3D printing minced shrimp-edible gum composition and preparation method thereof

A 3D printing and composition technology, which is applied in the field of 3D printing shrimp minced meat-edible glue composition and its preparation, can solve problems such as poor stability, and achieve the effects of reducing clogging, high economic benefit and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and comparative example 3D

[0031] Embodiment and comparative example 3D printing shrimp mince-edible glue composition

[0032] The 3D printed shrimp mince-edible gum composition of the embodiment and the comparative example consists of shrimp mince, 3% salt of shrimp mince quality, 3% cooking wine, 1% monosodium glutamate, 1% white granulated sugar and edible gum (carrageenan KC, Konjac Gum KG, Xanthan Gum XG, Curdlan Gum (CU), and the edible gum and its addition amount are shown in Table 1.

Embodiment 1~9

[0033] Table 1 The edible glue and the amount added of the 3D printed shrimp minced meat-edible glue composition of Examples 1-9

[0034]

[0035]

[0036] The preparation method of described 3D printing shrimp minced meat-edible gum composition comprises the following steps:

[0037] Under the condition of 2-5°C, remove the heads, shells, and guts of fresh shrimps to obtain shrimp meat, first empty the ground for 5 minutes, add 3% of the mass of the shrimp meat and grind for 2 minutes, and then add the mass of the shrimp meat 3% % cooking wine, 1% monosodium glutamate, 1% white granulated sugar and grind for 2 minutes, and finally add edible rubber and grind for 2 minutes to get it.

experiment example 1

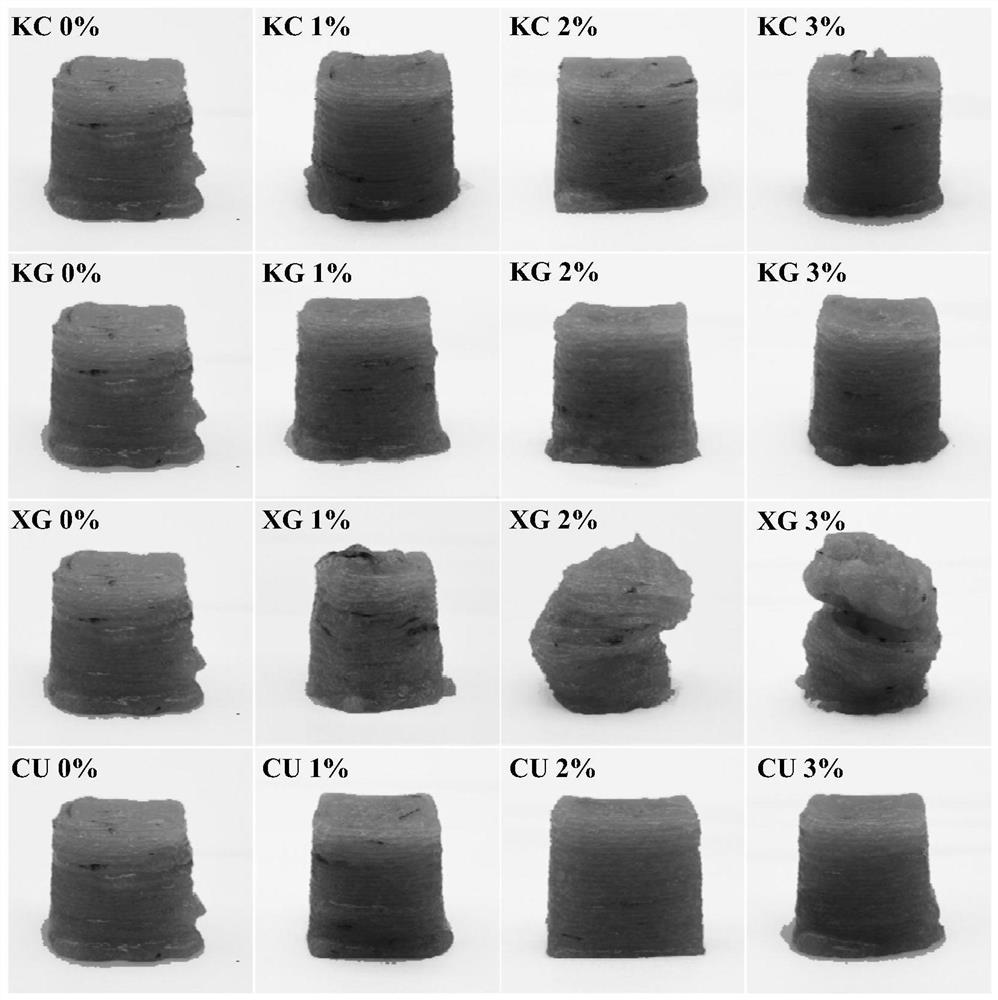

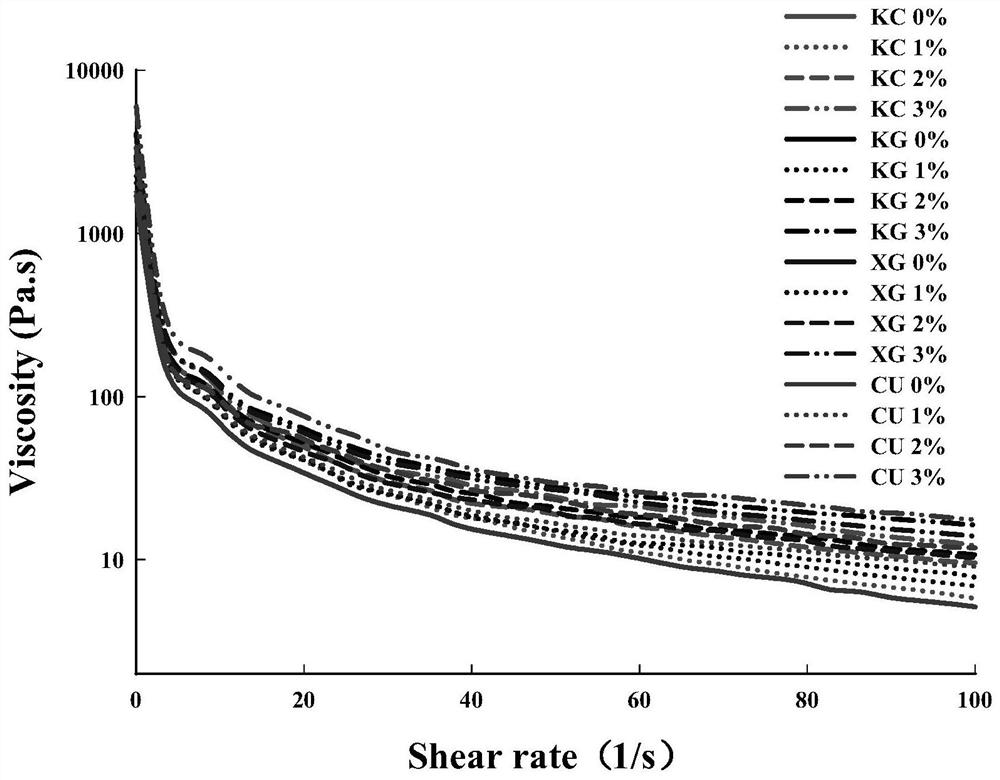

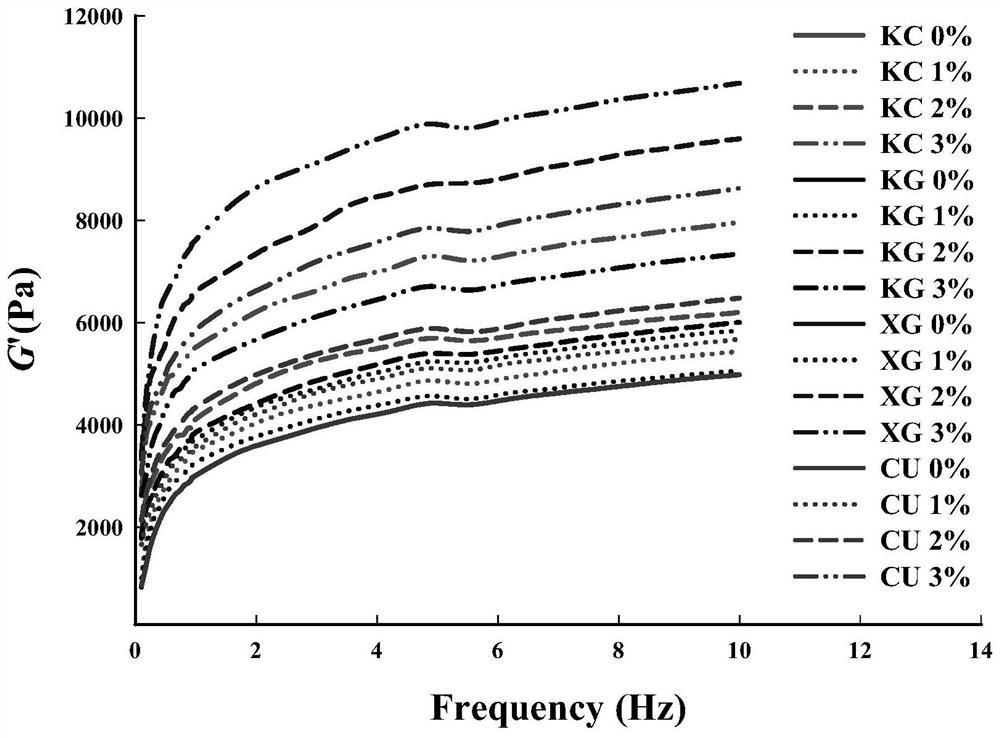

[0038] Experimental Example 1 Composition 3D Printing Accuracy and Stability

[0039] The 3D printed shrimp minced meat-edible glue compositions of Examples 1-9 and Comparative Examples 1-4 were 3D printed with a nozzle with a diameter of 1.20 mm, and the molding effect of the printed product was recorded in an LED light box, and the thickness of the printed product was measured with a vernier caliper. The side length and height are compared with the ideal size of the target model, and the printing accuracy is evaluated by the ratio of the length of the printed object to the length of the model. All printed products were placed in a room temperature environment of 25°C for 60 minutes to measure the height and calculate the printing stability index of the product.

[0040]

[0041]

[0042] In the formula: L s is the side length of the sample (mm); L m is the side length of the model (mm); H 0min The height of the sample at 0min (mm); H 60min It is the height (mm) of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com