Two-stage superheater desuperheating water system capable of independently taking water

A secondary superheater and superheater technology, applied in the control of superheated temperature, steam superheating, lighting and heating equipment, etc., can solve the problem of increasing the operating workload of operators, small pressure difference between desuperheating water and superheated steam, and superheating desuperheating water. Problems such as the inability to put into operation normally, to achieve the effect of not affecting the cooling effect, improving the steam temperature, and not increasing the operation switching operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

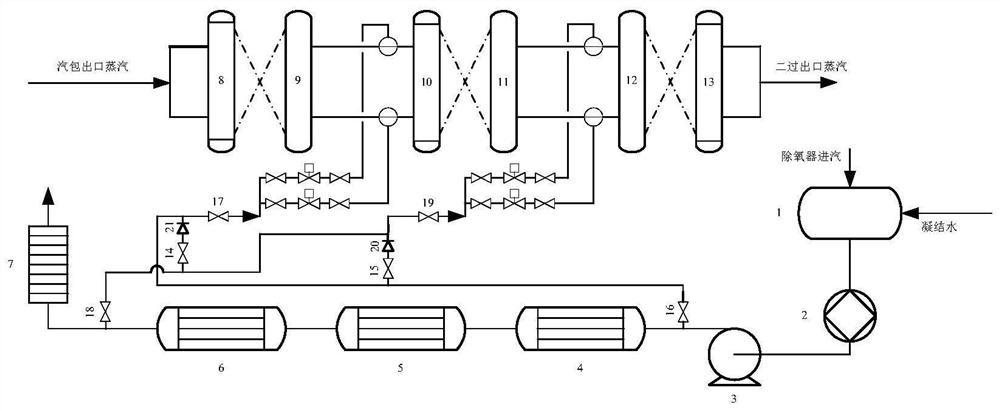

[0018] refer to figure 1 , the two-stage superheater desuperheating water system for independently taking water according to the present invention includes a deaerator 1, a front pump 2, a feed water pump 3, a No. 3 high-pressure heater 4, a first main pipe electric gate valve 16, and a No. 2 high-pressure heating Device 5, No. 1 high-pressure heater 6, economizer 7, second main pipe electric gate valve 18, first electric contact gate valve 15, first contact main pipe check valve 20, main pipe of secondary water supply system under separate water intake mode Electric gate valve 19, separate water intake mode, the main pipe electric gate valve of the next stage water supply system 17, the second electric contact gate valve 14, the second contact main pipe check valve 21, the inlet header of the panel superheater 10, the inlet header of the second stage superheater Box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com