Lithium niobate up-conversion luminescent material with core-shell structure and preparation method of lithium niobate up-conversion luminescent material

A technology of luminescent materials and core-shell structure, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low phonon energy, unfavorable up-conversion luminous efficiency, and failure to maintain, achieve excellent performance and improve up-conversion luminous efficiency , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

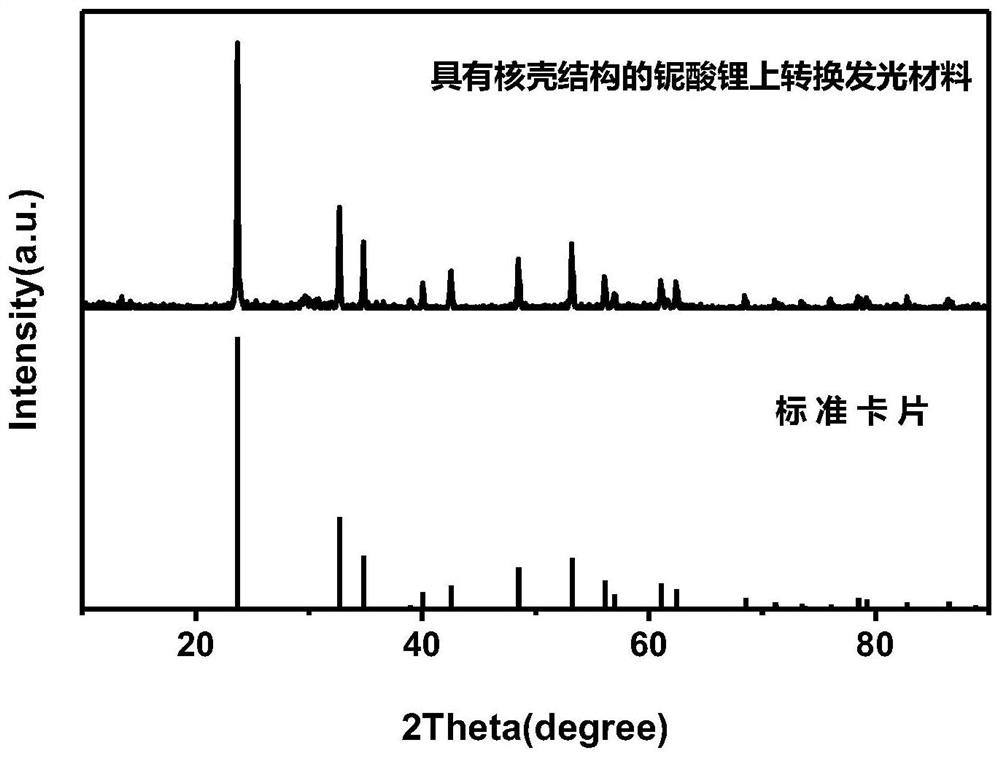

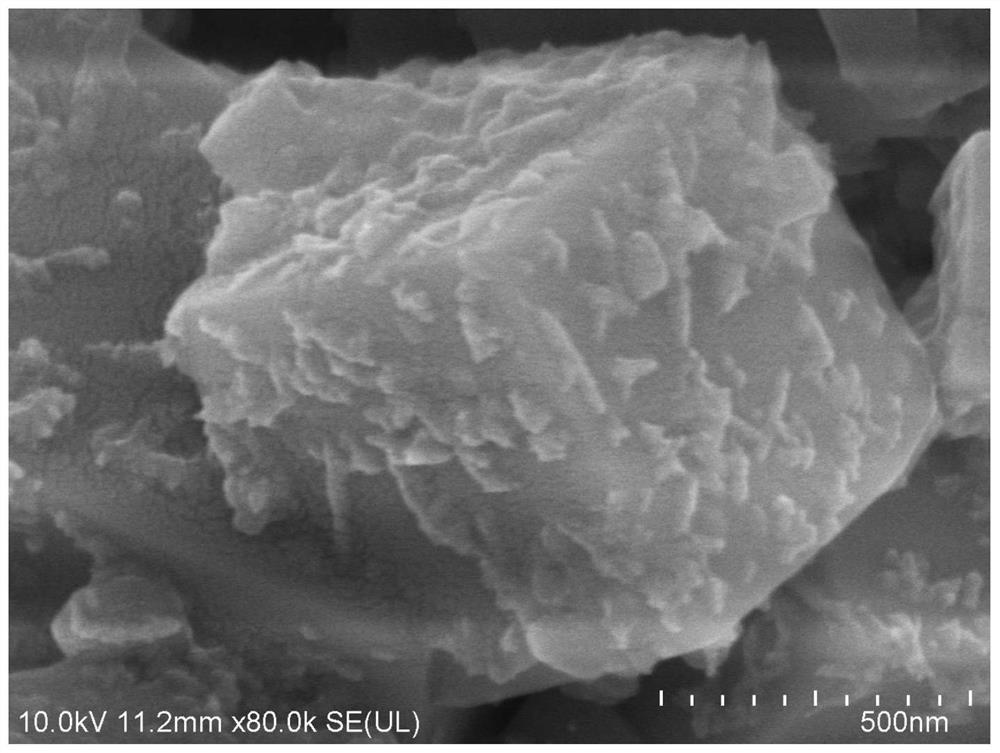

Embodiment 1

[0038](1) Weigh 0.5351g of lithium hydroxide monohydrate, 1.0359g of niobium pentoxide, 0.1214g of ytterbium nitrate pentahydrate and 0.0399g of erbium nitrate pentahydrate, add them to the reactor, and add 40ml deionized water and 40ml ethylene glycol . Incubate at 270°C for 24h. When the reactor is cooled to room temperature, it is centrifuged to dry and ground. Calcined in a muffle furnace at 1100°C for 2h. When the muffle furnace is cooled to room temperature, the lithium niobate upconversion luminescent material is obtained by grinding again.

[0039](2) Weigh 0.0546g of lithium hydroxide monohydrate, 0.1331g of niobium pentoxide and 0.0123g of ytterbium nitrate pentahydrate, and then weigh 0.1g of the lithium niobate upconversion luminescent material obtained in step (1) into the reactor And add 40ml deionized water and 40ml ethylene glycol. The reaction kettle was sonicated for 30 minutes. Then keep it at 270°C for 24h. When the reactor is cooled to room temperature, it is centr...

Embodiment 2

[0042](1) Weigh 0.5351g of lithium hydroxide monohydrate, 1.0359g of niobium pentoxide, 0.1214g of ytterbium nitrate pentahydrate and 0.0399g of erbium nitrate pentahydrate, add them to the reactor, and add 40ml deionized water and 40ml ethylene glycol . Incubate at 270°C for 24h. When the reactor is cooled to room temperature, it is centrifuged to dry and ground. The lithium niobate up-conversion luminescent material is obtained.

[0043](2) Weigh 0.0546g of lithium hydroxide monohydrate, 0.1331g of niobium pentoxide and 0.0123g of ytterbium nitrate pentahydrate, and then weigh 0.1g of the lithium niobate material obtained in step (1) into the reactor, and Add 40ml deionized water and 40ml ethylene glycol. The reaction kettle was sonicated for 30 minutes. Then keep it at 270°C for 24h. When the reactor is cooled to room temperature, it is centrifuged to dry and ground. Calcined in a muffle furnace at 1100°C for 2h. When the muffle furnace is cooled to room temperature, it is ground ag...

Embodiment 3

[0046](1) Weigh 0.5351g of lithium hydroxide monohydrate, 1.0359g of niobium pentoxide, 0.1214g of ytterbium nitrate pentahydrate and 0.0399g of erbium nitrate pentahydrate, add them to the reactor, and add 40ml deionized water and 40ml ethylene glycol . Incubate at 270°C for 24h. When the reactor is cooled to room temperature, it is centrifuged to dry and ground. Calcined in a muffle furnace at 800°C for 2h. When the muffle furnace is cooled to room temperature, it is ground again to obtain a lithium niobate upconversion luminescent material.

[0047](2) Weigh 0.0546g of lithium hydroxide monohydrate, 0.1331g of niobium pentoxide and 0.0123g of ytterbium nitrate pentahydrate, and then weigh 0.1g of the lithium niobate upconversion luminescent material obtained in step (1) into the reactor And add 40ml deionized water and 40ml ethylene glycol. The reaction kettle was sonicated for 30 minutes. Then keep it at 270°C for 24h. When the reactor is cooled to room temperature, it is centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com