Light-weight high-strength heat-insulation composite material plate and preparation method thereof

A technology of composite materials and panels, applied in the field of light-weight and high-strength thermal insulation composite panels and their preparation, to achieve the effects of improving oil absorption value and interface bonding force, high and low thermal conductivity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

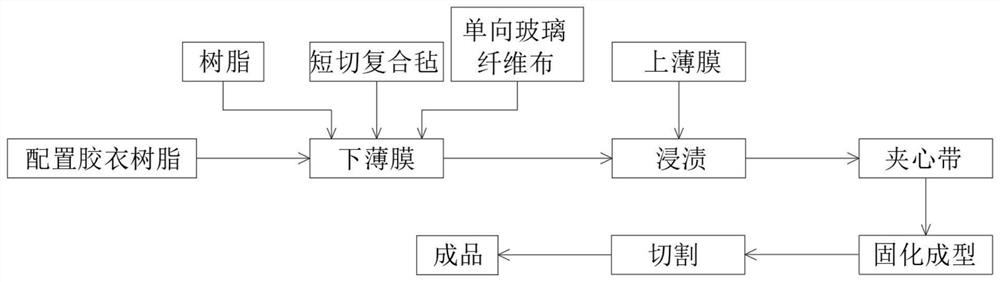

Method used

Image

Examples

example 1

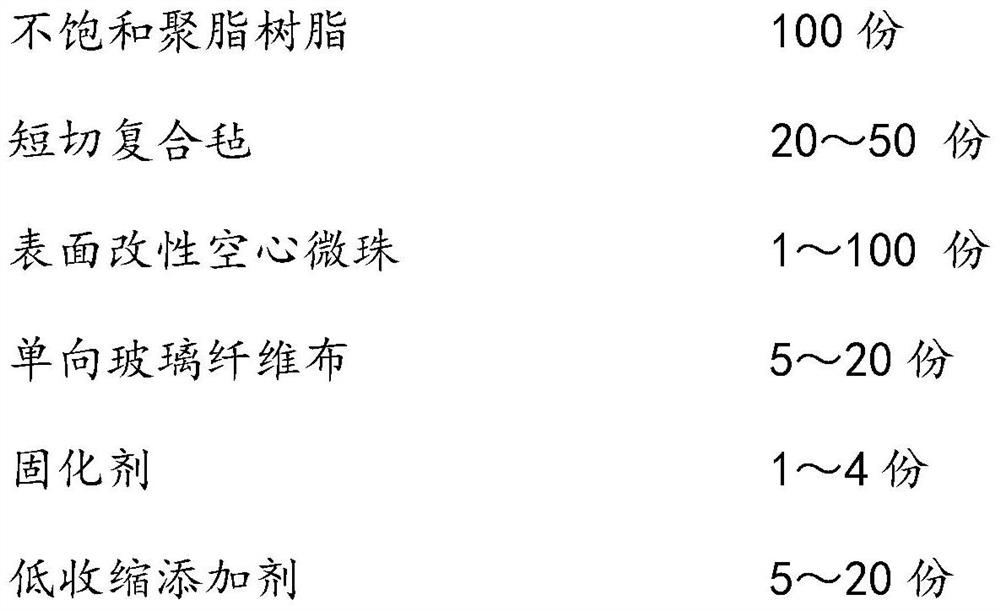

[0035] 1) Pour 10kg of o-phthalic unsaturated polyester resin, 1kg of polystyrene, 8kg of coupling agent KH550 surface-modified hollow microspheres, and 0.2kg of benzoyl peroxide into a blender to mix and stir Obtain resin paste evenly;

[0036] 2) Lay a layer of 0.3kg unidirectional glass fiber cloth on the surface of the polyester lower film, then flow the resin paste in 1) from the valve to the fiber cloth, and 2.75kg of chopped composite felt settles on the fiber cloth after cutting, Then lay a layer of 0.3kg unidirectional glass fiber cloth, first pass through the pressure roller, then cover the polyester film, and finally squeeze through the roller, and the fiber is impregnated with resin to obtain a prepreg;

[0037] 3) The prepreg enters the curing zone, and is cured and formed at 0.7MPa pressure and 80°C;

[0038] 4) After the curing is completed, the polyester upper film and the lower film are recycled, and the board is cut into a certain size to obtain a finished p...

example 2

[0043] 1) Pour 10kg of o-phthalic unsaturated polyester resin, 1kg of polystyrene, 8kg of coupling agent KH550 surface-modified ceramic microbeads, and 0.2kg of benzoyl peroxide into a blender to mix and stir Obtain resin paste evenly;

[0044] 2) Lay a layer of 0.3k unidirectional glass fiber cloth on the surface of the polyester lower film, then flow the resin paste in 1) from the valve to the fiber cloth, and 2.75kg of chopped composite felt settles on the fiber cloth after cutting, Then lay a layer of 0.3kg unidirectional glass fiber cloth, first pass through the pressure roller, then cover the polyester film, and finally squeeze through the roller, and the fiber is impregnated with resin to obtain a prepreg;

[0045] 3) The prepreg enters the curing zone, and is cured and formed at 0.7MPa pressure and 80°C;

[0046] 4) After the curing is completed, the polyester upper film and the lower film are recycled, and the board is cut into a certain size to obtain a finished pro...

example 3

[0051] 1) the benzoyl peroxide of the ortho-phthalic unsaturated polyester resin of 10kg, the polystyrene of 1kg, the coupling agent KH550 surface modification hollow glass microsphere of 4kg, 0.2kg are poured into the stirrer and mixed and Stir evenly to obtain a resin paste;

[0052] 2) Lay a layer of 0.3kg unidirectional glass fiber cloth on the surface of the polyester lower film, then flow the resin paste in 1) from the valve to the fiber cloth, and 2.75kg of chopped composite felt settles on the fiber cloth after cutting, Then lay a layer of 0.3kg unidirectional glass fiber cloth, first pass through the pressure roller, then cover the polyester film, and finally squeeze through the roller, and the fiber is impregnated with resin to obtain a prepreg;

[0053] 3) The prepreg enters the curing zone, and is cured and formed at 0.7MPa pressure and 80°C;

[0054] 4) After the curing is completed, the polyester upper film and the lower film are recycled, and the board is cut int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com