Preparation method of oxacillin sodium and oxacillin sodium for injection

A technology of oxacillin sodium and crystal seed is applied in the field of oxacillin sodium preparation, and can solve the problems of poor fluidity of oxacillin sodium powder, low yield of injection oxacillin sodium sub-packaging, etc. Achieve uniformity and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

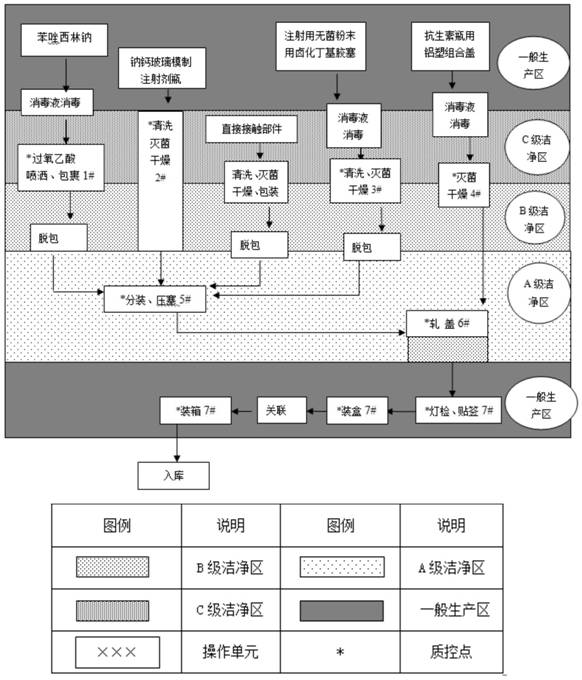

Image

Examples

Embodiment 1

[0037] 1. Condensation:

[0038] Prepare the buffer first: add 840L high-purity water to the crystallization tank, control the temperature of the water at 26-27°C, start stirring, then add 3.5kg sodium dihydrogen phosphate and 0.33kg ammonium chloride to dissolve, and add 18kg6- APA was stirred until completely dissolved to obtain a clear and transparent solution, then 20 kg of acid chloride was added, and the pH was adjusted to 6.8-7.0 with NaOH solution, and the reaction was carried out for 2 hours.

[0039] 2. Acidification extraction:

[0040] After the condensation reaction is completed, add activated carbon, stir and filter, add 240L butyl acetate to the filtrate, add dropwise H 2 SO 4 , adjust PH=2.0 left and right, stir, stand and separate layers, collect the upper layer filtrate, then add 80L butyl acetate to the upper layer filtrate, again use H 2 SO 4 Adjust the pH to about 2.0, stir, and let stand for the second time to separate layers, collect the upper layer ...

Embodiment 2

[0056] 1. Condensation:

[0057]Prepare the buffer first: add 840L high-purity water to the crystallization tank, control the temperature of the water at 26-27°C, start stirring, then add 3.5kg sodium dihydrogen phosphate and 0.33kg ammonium chloride to dissolve, and add 18kg6- APA was stirred until completely dissolved to obtain a clear and transparent solution, then 20 kg of acid chloride was added, and the pH was adjusted to 6.8-7.0 with NaOH solution, and the reaction was carried out for 2 hours.

[0058] 2. Acidification extraction:

[0059] After the condensation reaction is completed, add activated carbon, stir and filter, add 240L butyl acetate to the filtrate, add dropwise H 2 SO 4 , adjust PH=2.0 left and right, stir, stand and separate layers, collect the upper layer filtrate, then add 80L butyl acetate to the upper layer filtrate, again use H 2 SO 4 Adjust the pH to about 2.0, stir, and let stand for the second time to separate layers, collect the upper layer f...

Embodiment 3

[0073] The difference between this embodiment and Example 2 is that oxacillin sodium seed crystals are added in the crystallization process, and the introduction of crystal seeds is beneficial to ensure the number and uniformity of crystal nuclei, and ensure the uniformity of the particle size of the grown crystals. Specifically, the extract is added to a crystallization tank, and a seed crystal is added, and then sodium acetate solution is added for a crystallization reaction.

[0074] The preparation method of the oxacillin sodium seed crystal is as follows: the sodium acetate solution with a concentration of 10-12% is slowly added dropwise to the extract solution, the dropping speed is 2L / min, and the dropping speed is such that the crystallization temperature is controlled at 40- 50°C, react for 8-10min, wash the crystals, and dry.

[0075] The added amount of the seed crystal is 2% based on oxacillin sodium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com