Bionic lamellar thermal insulation material

A heat insulation material and bionic layer technology, applied in the field of refractory materials, can solve the problems of reducing heat convection and heat radiation, limiting heat conduction, and inability to use, so as to reduce thermal conductivity and thickness of heat insulation layer, reduce heat conduction, and reduce sintering shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the bionic layered thermal insulation material of this embodiment is as follows: Weigh alumina micropowder (86% by weight, particle size is 0.03 mm), aluminum silicate fiber (10% by weight), starch (10% by weight 1 %) and BBP (3% by weight), put them all into a mixer, stir at a speed of 1000 r / min for 30 min, mix thoroughly to obtain a slurry with a certain viscosity, and then mix well Thin-layer units of the slurry were prepared using the spin-coating method with a thickness of 2 mm.

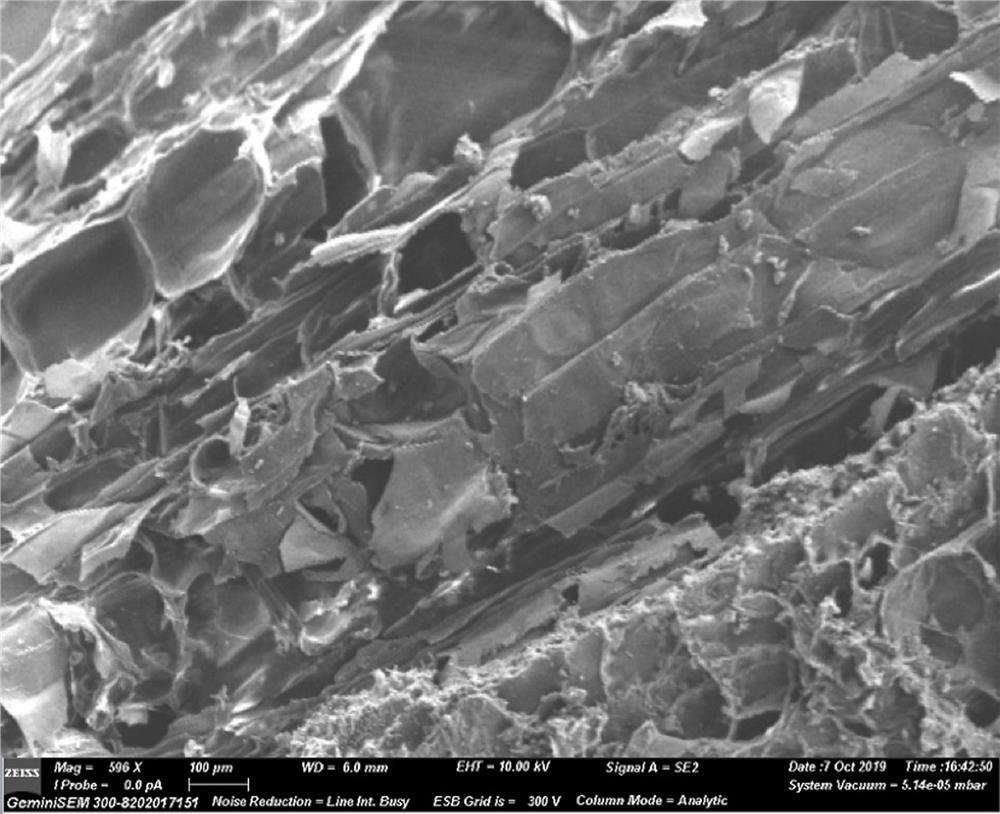

[0028] The prepared thin-layer units are bonded and laminated, and a silica sol adhesive is added between the units to obtain a green body. Dry the obtained body in a drying oven at 100 °C for 12 hours to obtain a bionic layered thermal insulation material 1 with a thickness of 40 mm and a layered structure (the same structure as the bark of the American redwood tree, both of which are layered structure, such as figure 2 shown), including 20 thin-layer units ...

Embodiment 2

[0031] The preparation method of the biomimetic layered thermal insulation material in this example is: weigh the mixture of fumed silica and alumina micropowder (the weight ratio of the two is 1:1, the total weight ratio is 88%, and the particle size is 0.04 mm) , mullite fiber (9% by weight), silicon carbide (1% by weight) and PEG-400 (2% by weight), put them all into a mixer and set the temperature at 1000 r / min Stir at a high speed for 30 min, mix thoroughly to obtain a slurry with a certain viscosity, and then use the scraping method to prepare a thin-layer unit with a thickness of 3 mm.

[0032] The prepared thin-layer units are bonded and laminated, and polyvinylpyrrolidone adhesive is added between the units to obtain a green body. The green body obtained was dried in a drying oven at 90°C for 12 hours to obtain a biomimetic layered thermal insulation material 1 with a thickness of 45 mm and a layered structure including 15 thin-layer units 2 .

[0033] Then the therm...

Embodiment 3

[0035] The preparation method of the biomimetic layered thermal insulation material of this embodiment is as follows: Weigh alumina micropowder (90% by weight, particle size is 0.03mm), zirconia fiber (5% by weight), silicon carbide ( 1 %) and BBP (4% by weight), put them all into a mixer, stir at a speed of 1000 r / min for 30 min, mix thoroughly to obtain a slurry with a certain viscosity, and then mix well Thin-layer units of the slurry were prepared using the spin-coating method with a thickness of 2 mm.

[0036] The prepared thin-layer units are bonded and laminated, and a silica sol adhesive is added between the units to obtain a green body. The obtained body was dried in a drying oven at 150 °C for 12 hours to obtain a biomimetic layered thermal insulation material 1 with a thickness of 40 mm and a layered structure including 20 thin-layer units 2 .

[0037] Then the thermal conductivity of the obtained product is tested, which can be used in the temperature range below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com