Method for evaluating filamentous corrosion resistance of aluminum wheel finish turning surface

A technology for filiform corrosion and aluminum wheels, which is applied in the field of evaluating the filiform corrosion resistance of aluminum wheels, can solve problems such as node lag, uneven coating, and the inability to effectively evaluate quality risks in the development stage of parts, so as to reduce The effect of the evaluation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

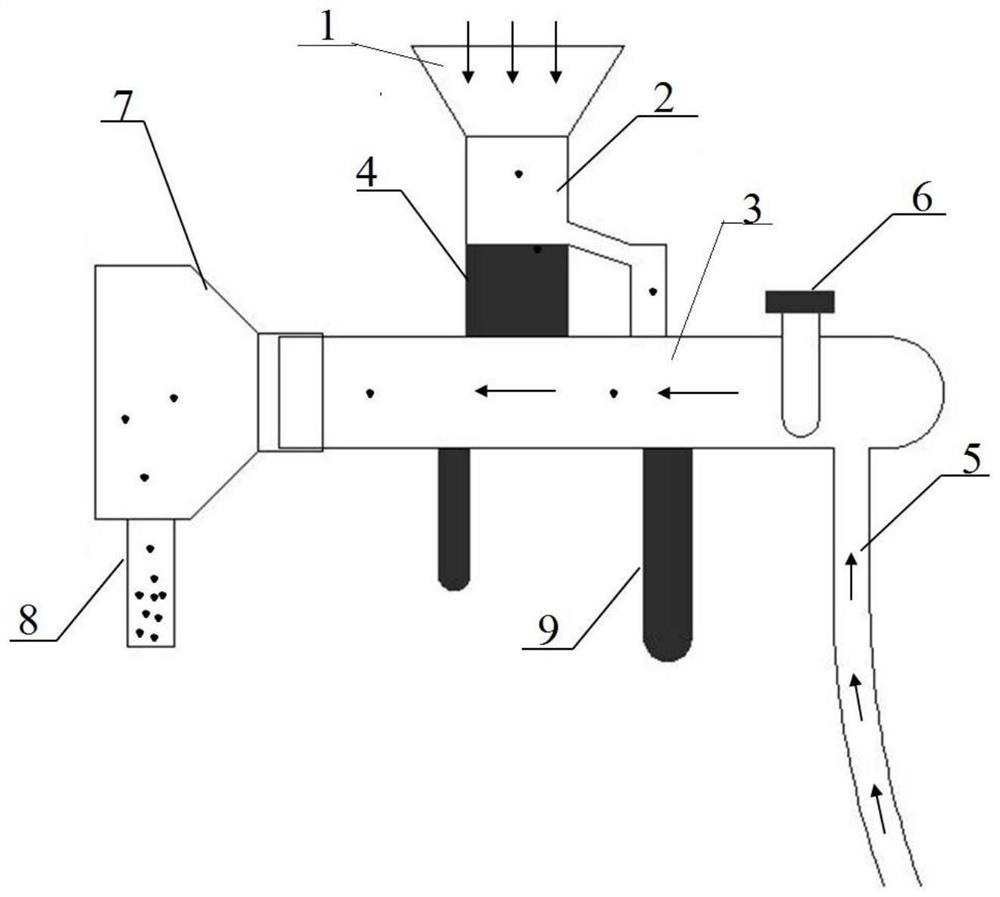

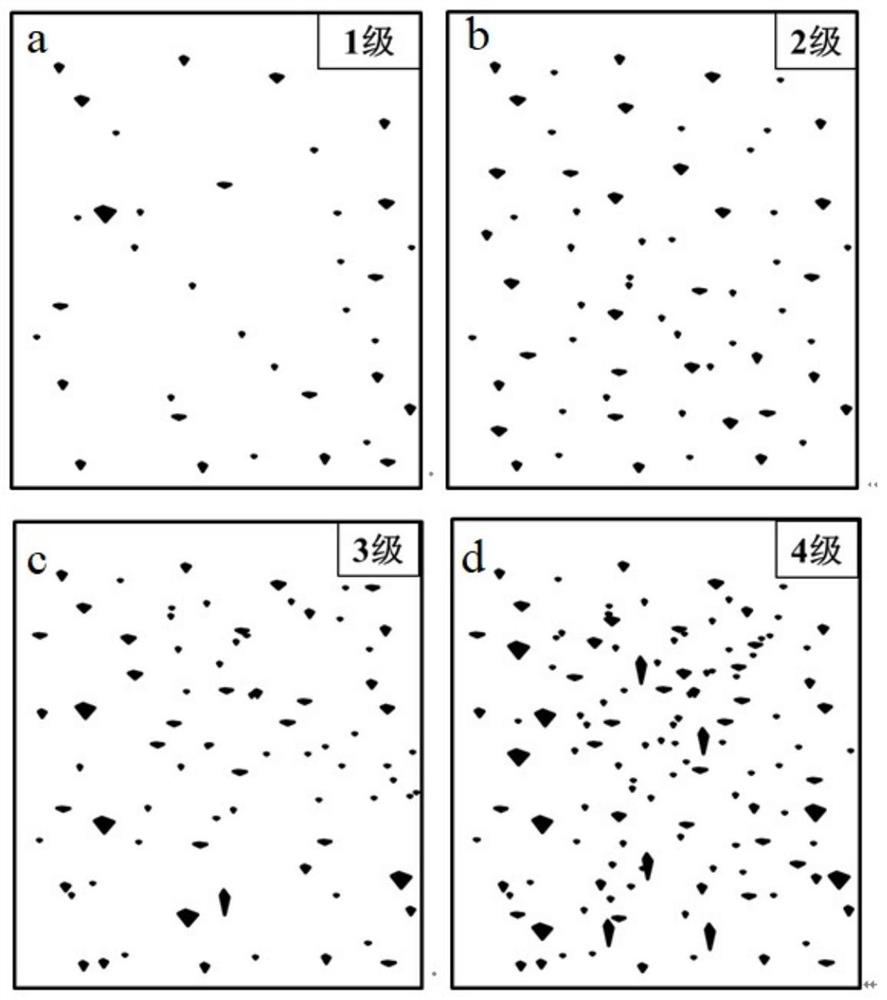

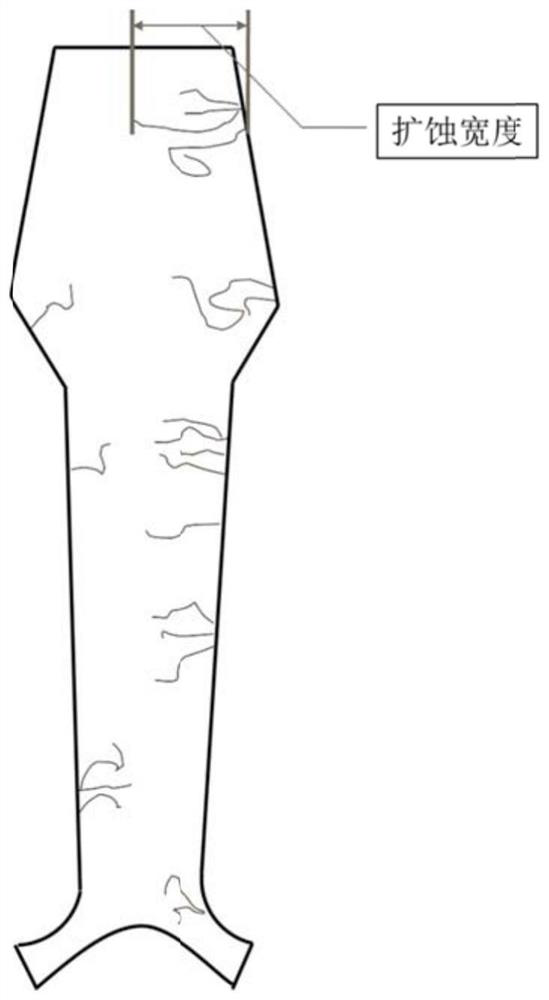

Method used

Image

Examples

Embodiment

[0073] In order to further illustrate that the evaluation method designed by the present invention does have guiding significance for the actual production of aluminum wheels, this embodiment explores the fine surface of aluminum wheels with different edge paint film thicknesses to simulate the above-mentioned stone impact and salt spray tests, and the corrosion conditions obtained are shown in the table 1 shown;

[0074] Table 1 Corrosion of aluminum wheel finish surface with different paint film thickness

[0075]

[0076]It can be seen from the above examples that the evaluation method designed by the present invention is closely related to the actual production of aluminum wheels, and the accuracy of the final evaluation result is relatively good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com