A supply chain carbon footprint information automatic collection and management system

A management system and automatic collection technology, applied in the field of energy conservation and environmental protection, can solve the problems of long cycle, time-consuming acquisition of carbon emission inventory data, etc., achieve the effect of reducing evaluation cycle and cost, realizing automatic collection and management, and facilitating certification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

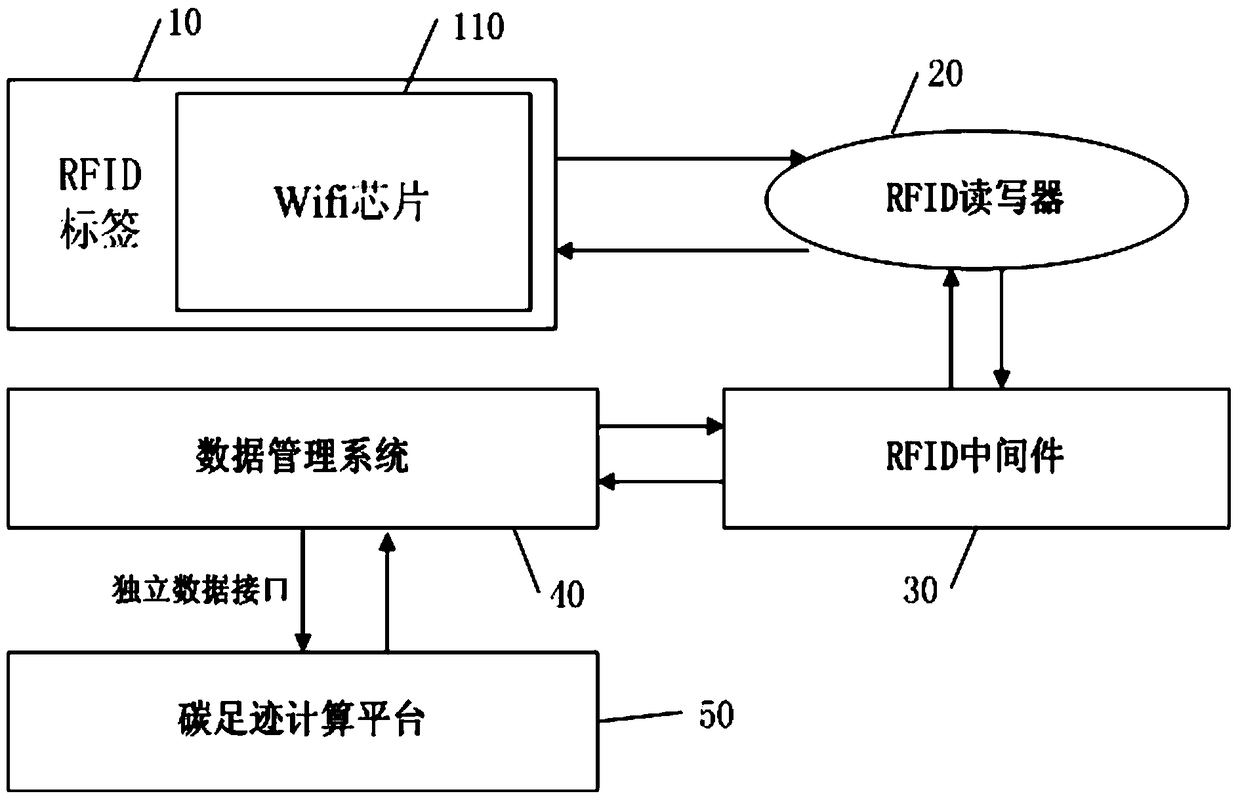

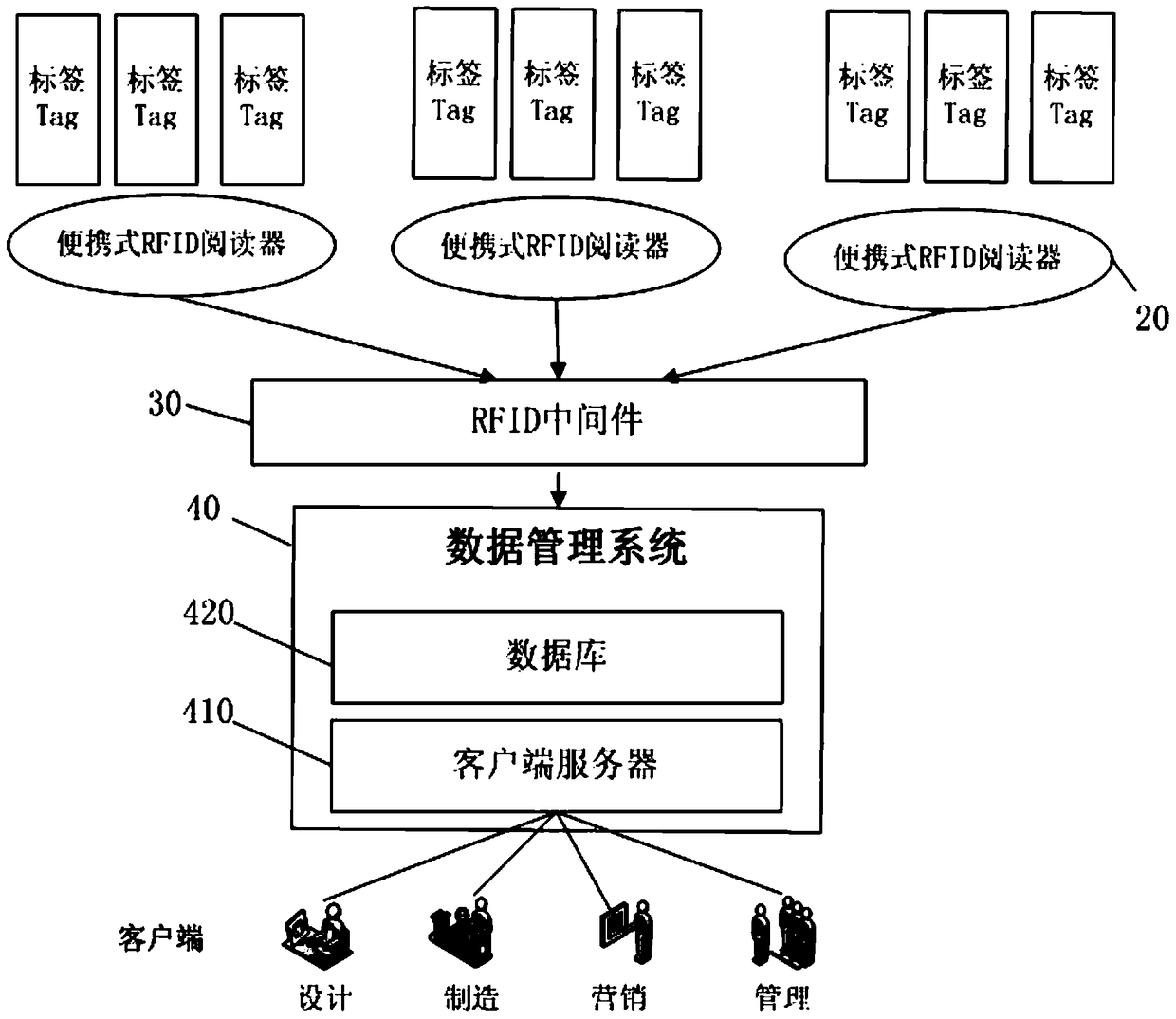

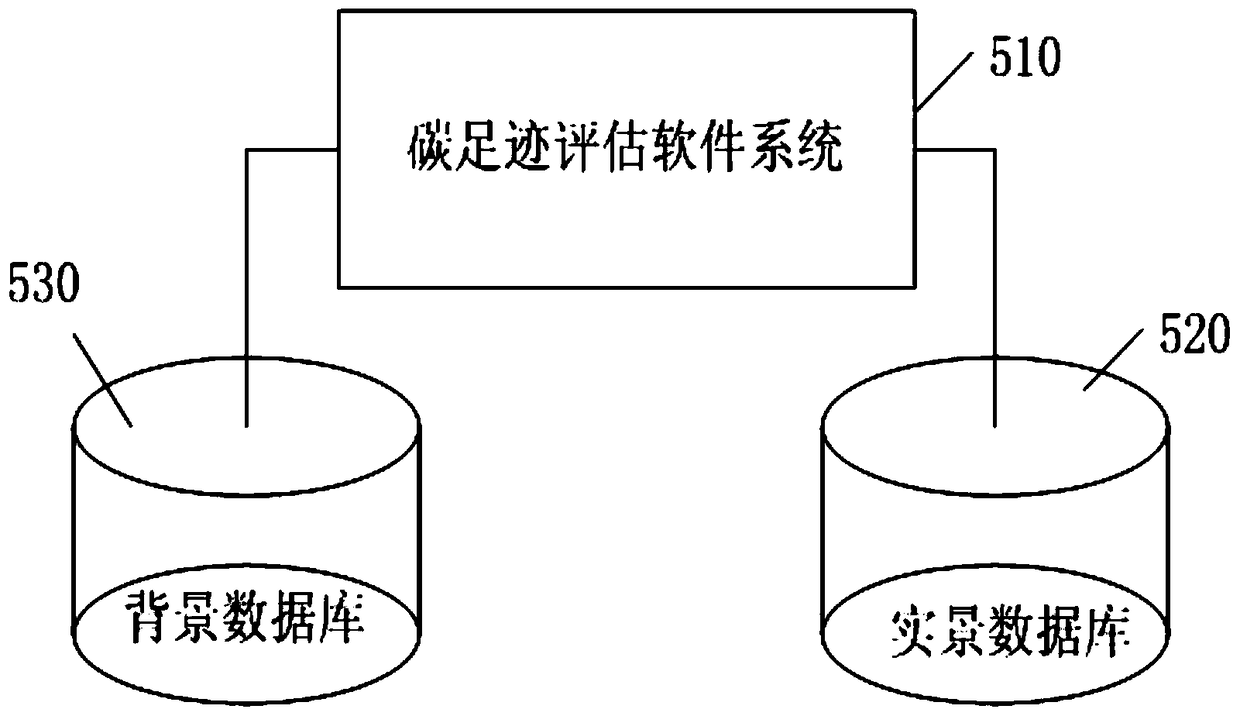

Method used

Image

Examples

Embodiment

[0043] Taking the automatic collection and management of carbon footprint information of a refrigerator supply chain of a refrigerator company as an example, the system is used to collect the carbon footprint information of purchased parts and realize the calculation of the carbon footprint of refrigerators.

[0044] (1) The storage manager of the refrigerator material uses the RFID portable reader to read the carbon footprint information of the various parts supplied. The RFID tags of the supplied parts should include the part name, model, carbon footprint, and supplier name , transportation distance and other data. For example, taking the refrigerator compressor as an example, the RFID tag records that its name is compressor, its model is HYS69MKUa, and its carbon footprint is 8.24kgCO 2 e, the supplier is Jiacibera, the transportation distance is 442km, and the transportation method is automobile.

[0045] (2) Storage and review of carbon footprint information of purchased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com