Antibacterial anti-ultraviolet thermochromic wax painting pigment and preparation method thereof

A thermochromic and anti-ultraviolet technology, applied in the field of pigments, can solve the problems of poor bonding fastness, precipitation, and poor wall material dispersibility, and achieve the effects of fast thermal response speed, improved thermal conductivity, and high bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

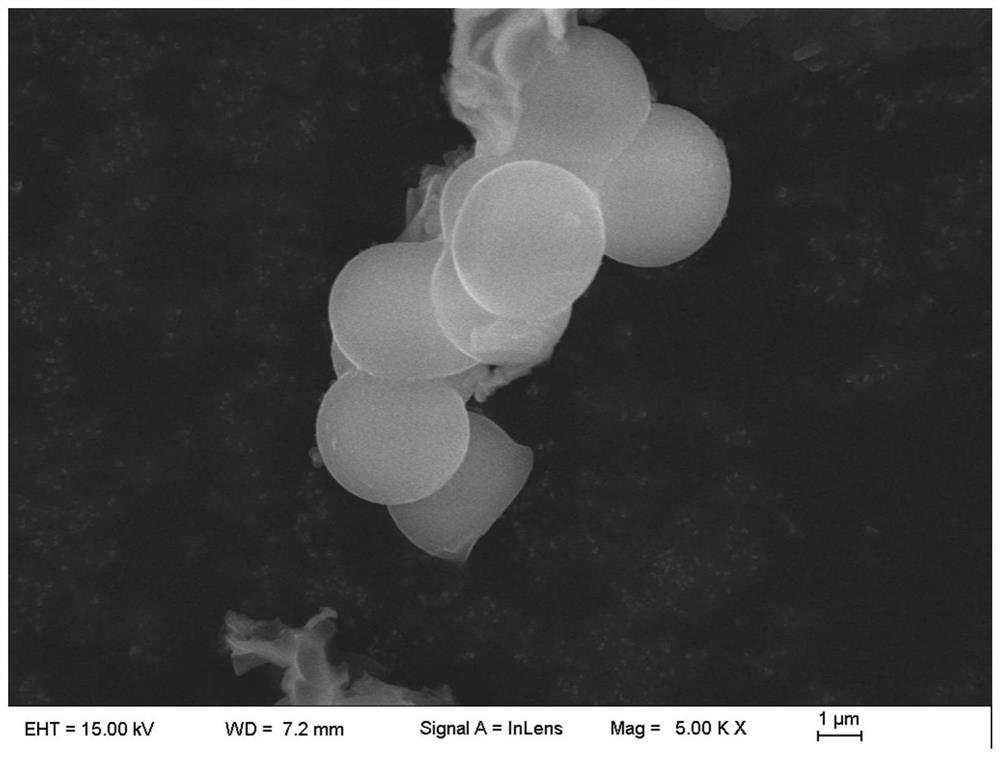

Image

Examples

preparation example Construction

[0064]A preparation method of wax color paint includes the following steps:

[0065](1) According to the mass ratio (65-75):1:(3-7), weigh the temperature control agent (fatty alcohol or lipid compound), color developing agent, organic thermochromic material, and color developing agent bisphenol A into the container Heat and stir in a water bath at 80-90°C for 1-2 hours to obtain a thermochromic compound; the organic thermochromic material is crystal violet lactone, thermosensitive red or thermosensitive green; the fatty alcohol is myristyl alcohol , The lipid compound is methyl stearate.

[0066](2) According to the mass ratio (0.8-1.2): (0.8-1.2), mix the thermosensitive color-changing compound with ethyl orthosilicate, stir at 30-45°C for 25-35 min, and add to the concentration with formamide as the solvent In the 1.1-1.2g / 80-120mL cetyltrimethylammonium bromide solution, the reaction is stirred at 1200-1500rpm for 3-5h to obtain a uniform dispersion emulsion. The solid-liquid ratio of...

Embodiment 1

[0074](1) Place 1 g of crystal violet lactone, 5 g of bisphenol A, and 70 g of tetradecanol in a beaker, heat and stir in a water bath at 90° C. for 2 hours to obtain a thermosensitive color-changing compound.

[0075](2) Add 7g of thermosensitive color-changing compound and 7g of ethyl orthosilicate into a container and mix, stir at 35°C for 35min, and add to 100mL 1.15g cetyltrimethylammonium bromide solution with formamide as solvent The reaction was carried out at 1500 rpm for 3 hours to obtain a uniform dispersion emulsion.

[0076](3) Adjust the rotation speed to 700 rpm, take 100 mL of 1 mol / L hydrochloric acid solution, add dropwise to the dispersion emulsion at 2 drops / s, and react for 5 hours to obtain a precipitate.

[0077](4) Stop stirring, keep the temperature at 50°C, mature for 18h, pour out, centrifuge, wash, and dry the product at 80°C after completion to obtain silica-coated thermochromic compound microcapsules.

[0078](5) Take 1.5 g of silica-coated thermochromic compound m...

Embodiment 2

[0083](1) Place 1g of thermosensitive red, 7g of bisphenol A, and 65g of methyl stearate in a beaker, heat and stir in a water bath at 80°C for 1.5 hours to obtain a thermosensitive compound.

[0084](2) Add 7.5g thermosensitive color-changing compound and 7.5g ethyl orthosilicate into the container and mix, stir at 40℃ for 30min, and add to 80mL 1.2g cetyltrimethyl bromide using formamide as solvent In the ammonium solution, react for 5 hours at 1200 rpm to obtain a uniform dispersion emulsion.

[0085](3) Adjust the speed to 500 rpm, take 100 mL of 1.2 mol / L hydrochloric acid solution, and add it dropwise to the dispersion emulsion at 2.5 drops / s, and react for 3 hours to obtain a precipitate.

[0086](4) Stop stirring, keep the temperature at 45°C, mature for 20h, pour out, centrifuge, wash, and dry the product at 75°C after completion to obtain silica-coated thermochromic compound microcapsules.

[0087](5) Take 1.3 g of silica-coated thermochromic compound microcapsules and mix with 100 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com