Semiconductor chip cleaning agent, preparation method and application thereof

A semiconductor and cleaning agent technology, applied in semiconductor/solid-state device manufacturing, preparation of detergent mixture composition, detergent composition, etc., can solve the problems of environmental operators' health hazards, wafer cracks, unfriendly environment, etc. Achieve the effect of good industrialization potential, excellent cleaning performance and excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

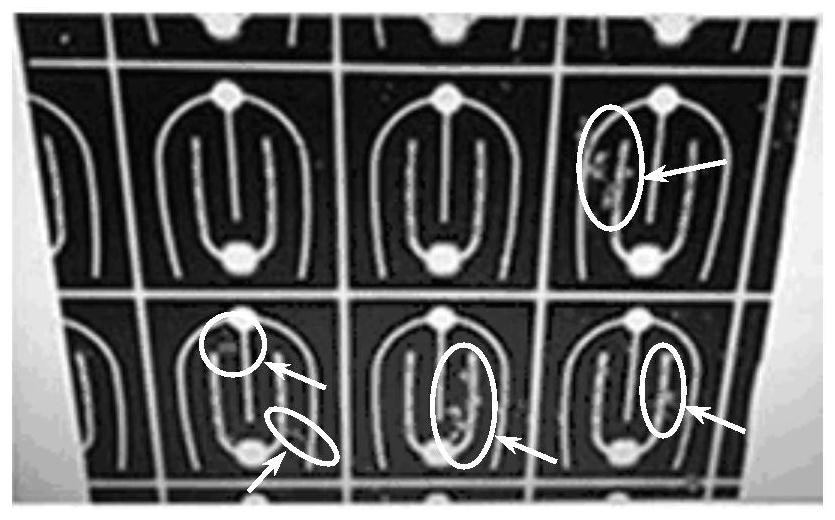

Image

Examples

Embodiment 1

[0068] S1: Based on the total mass percentage of 100%, weigh the following components in mass percentage: 4% of the wet-strip agent of the above formula (I) (wherein x=6), 3% of the perfluorinated terminal Base polyoxyethylene ether (where m=4 and n=8), 0.1% penetrant sodium 1,4-di(2-ethylhexyl) succinate sulfonate, 12% solubilizer n-dodecane , 2% composite functional agent 9,10-dihydroxystearic acid methyl ester, 2% nitrogen-containing complexing agent o-phenanthroline, 0.5% organic auxiliary diethanolamine and the high-purity water of the remainder (that is, the mass percentage is 76.4%);

[0069] S2: Add all components except pure water into the container, and heat it to 40°C under stirring until all materials are completely dissolved, then add 1 / 2 amount of composite functional agent (that is, 1% by mass percentage) while keeping stirring. said composite functional agent) and all ultrapure water, then heated up to 68°C, then added the remaining 1 / 2 amount of composite fun...

Embodiment 2

[0071] S1: Based on the total mass percentage of 100%, weigh the following components in mass percentage: 8% of the wet-strip agent of the above formula (I) (wherein x=6), 2% of the perfluorinated terminal Base polyoxyethylene ether (where m=4 and n=8), 0.5% penetrant sodium 1,4-di(2-ethylhexyl) succinate sulfonate, 6% solubilizer n-octadecane , 5% composite functional agent 9,10-dihydroxystearic acid methyl ester, 1% nitrogen-containing complexing agent o-phenanthroline, 1.5% organic auxiliary agent diglycolamine and the high-purity water of the remainder (that is, quality percentage is 76%);

[0072]S2: Add all components except pure water into the container, and heat to 50°C under stirring until all the materials are completely dissolved, then add 1 / 2 amount of composite functional agent (that is, 2.5% by mass percentage) while keeping stirring The composite functional agent) and all the ultrapure water are then heated up to 60°C, and then the remaining 1 / 2 amount of the c...

Embodiment 3

[0074] S1: Based on the total mass percentage of 100%, weigh the following components in mass percentage: 6% of the wet-strip agent of the above formula (I) (wherein x=6), 2.5% of the perfluorinated terminal base polyoxyethylene ether (where m=4 and n=8), 0.3% penetrant sodium 1,4-bis(2-ethylhexyl)succinate sulfonate, 9% solubilizer n-pentadecane , 3.5% composite functional agent 9, 10-dihydroxystearic acid methyl ester, 1.5% nitrogen-containing complexing agent o-phenanthroline, 1% organic additive diethanolamine laurate and the high-purity water (that is, quality percentage of 76.2%);

[0075] S2: Put all the components except pure water into the container, and heat it to 45°C under stirring until all the materials are completely dissolved, then add 1 / 2 amount of composite functional agent (that is, 1.75% by mass percentage) while keeping stirring. The composite functional agent) and all the ultrapure water, then heated up to 64°C, then added the remaining 1 / 2 amount of com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com