Preparation method of high-performance potassium-sodium niobate-based lead-free energy storage ceramic

A potassium-sodium niobate-based, high-performance technology, applied in fixed capacitor parts, fixed capacitor dielectrics, circuits, etc., can solve the problems of few researches on the characteristics of electric energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

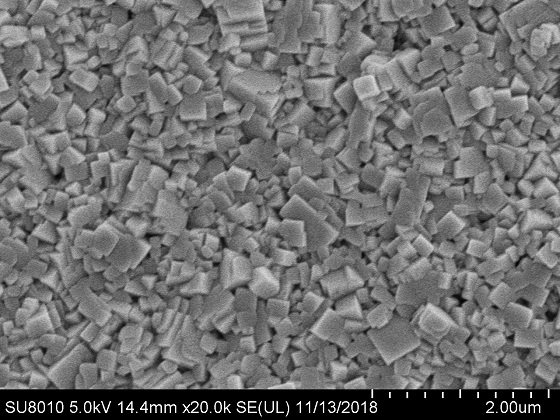

[0029] Example 1 Ceramic powder ball milled for 8 hours and KNN-based energy storage ceramics using a two-stage sintering method, the general chemical formula is 0.925 (K 0.5 Na 0.5 )NbO 3 –0.075Bi(Zn 2 / 3 (Ta 0.5 Nb 0.5 ) 1 / 3 )O 3 .

[0030] The specific preparation process of Example 1 includes the following steps.

[0031] (1) Weigh the raw materials according to the stoichiometric ratio of the general chemical formula, add them together with zirconia balls and absolute ethanol into a nylon ball mill jar, and place them on a planetary ball mill for ball milling and mixing for 12 hours.

[0032] (2) After drying the ball-milled mixture, place it in a muffle furnace for calcination at 850°C for 5 hours.

[0033] (3) After the pre-fired powder is ball milled for 8 hours and dried again, add an appropriate amount of polyvinyl alcohol binder for grinding and granulation, and unidirectional pressure molding at 2MPa to obtain a ceramic with a diameter of about 8mm and a thi...

Embodiment 2

[0036] Example 2 KNN-based energy storage ceramics with ceramic powder ball milled for 14 hours and two-stage sintering method, the general chemical formula is 0.925 (K 0.5 Na 0.5 )NbO 3 –0.075Bi(Zn 2 / 3 (Ta 0.5 Nb 0.5 ) 1 / 3 )O 3 .

[0037] The specific preparation process of Example 1 includes the following steps.

[0038] (1) Weigh the raw materials according to the stoichiometric ratio of the general chemical formula, add them together with zirconia balls and absolute ethanol into a nylon ball mill jar, and place them on a planetary ball mill for ball milling and mixing for 12 hours.

[0039] (2) After drying the ball-milled mixture, place it in a muffle furnace for calcination at 850°C for 5 hours.

[0040] (3) After the pre-fired powder is ball milled for 14 hours to dry again, add an appropriate amount of polyvinyl alcohol binder for grinding and granulation, and unidirectional pressure molding at 2MPa to obtain a ceramic with a diameter of about 8mm and a thickne...

Embodiment 3

[0043] Example 3 KNN-based energy storage ceramics with ceramic powder ball milled for 20 hours and two-stage sintering method, the general chemical formula is 0.925 (K 0.5 Na 0.5 )NbO 3 –0.075Bi(Zn 2 / 3 (Ta 0.5 Nb 0.5 ) 1 / 3 )O 3 .

[0044] The specific preparation process of Example 3 includes the following steps.

[0045] (1) Weigh the raw materials according to the stoichiometric ratio of the general chemical formula, add them together with zirconia balls and absolute ethanol into a nylon ball mill jar, and place them on a planetary ball mill for ball milling and mixing for 12 hours.

[0046] (2) After drying the ball-milled mixture, place it in a muffle furnace for calcination at 850°C for 5 hours.

[0047] (3) (3) After the calcined powder is ball milled for 20 hours and dried again, add an appropriate amount of polyvinyl alcohol binder for grinding and granulation, and unidirectional pressure molding at 2MPa to obtain a diameter of about 8mm and a thickness of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com