Fabricated steel structure manufacturing and machining process

A processing technology and steel structure technology, which is applied in the field of fabricated steel structure manufacturing and processing technology, can solve problems such as air pollution, high production costs, and large emissions of harmful gases, so as to achieve a clear manufacturing process, improve production quality, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

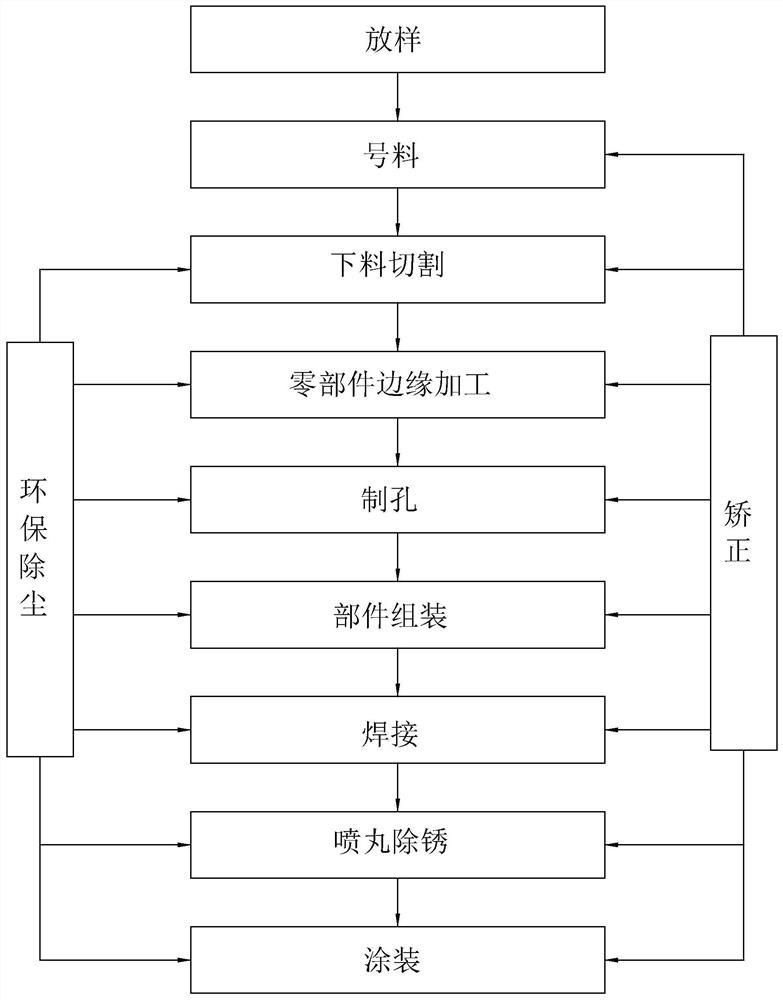

[0021] The following is attached figure 1 The application is described in further detail.

[0022] The embodiment of this application discloses a fabrication and processing technology of fabricated steel structure, refer to figure 1 , including the following steps: a. lofting; b. material number; c. blanking and cutting; d. edge processing of parts; e. hole making; f. correction; g. component assembly; h. welding and re-correction; i. Shot blasting and derusting; j, painting. Strictly follow the above steps to process the steel to obtain a better quality steel structure.

[0023] In step a, during the stakeout process, the following operations should be performed:

[0024] 1) When making the model, use a metal stylus to stake out to ensure the precision and accuracy of the model. Stakeout pops up a large sample on the sample platform at a ratio of 1:1. When the size of the large sample is too large, it can be popped up in sections; if the component only requires its nodes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com