Forming method of metal strip sealing tape

A forming method and a metal sealing technology, which are applied in the field of mechanical processing, can solve the problems of not finding the forming mold or forming method of the metal strip sealing tape parts, increasing the difficulty of processing and the cost of tooling, and achieving simple forming molds and fast manufacturing cycles. Effect of reducing and ensuring straightness and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

[0020] The present invention is achieved through the following technical solutions:

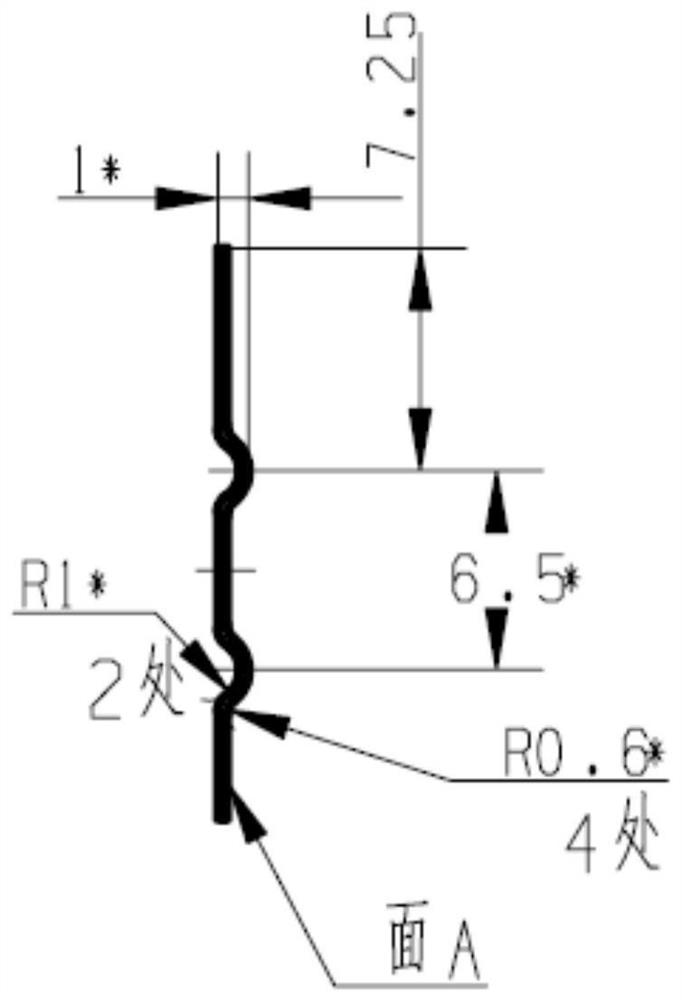

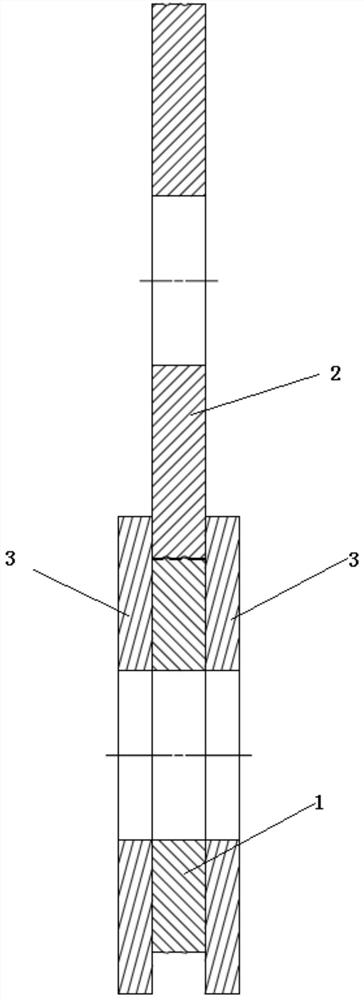

[0021] (1) Make the roller: design and manufacture the roller mold according to the structure of the parts, the roller is composed of upper and lower surface rollers and baffles 3 on both sides;

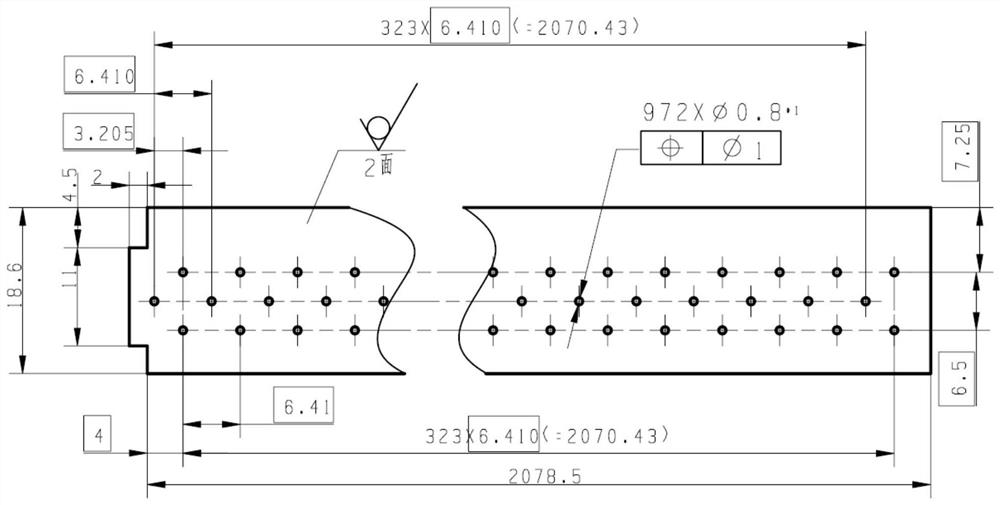

[0022] (2) Preparation of molding wool: the length of the wool is calculated by adding the reserved part length, and the width is calculated by multiplyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com