High-strength low-shrinkage lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery, low-shrinkage technology, applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of easy shrinkage and low strength, and achieve reduced thermal shrinkage, improved mechanical strength, and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

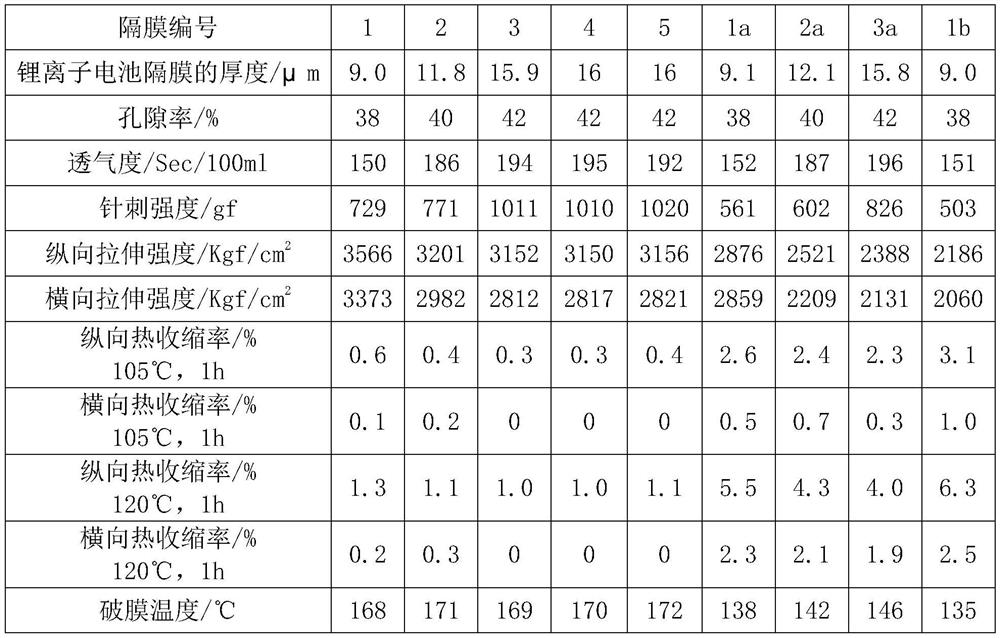

Examples

Embodiment 1

[0025] A preparation method of a lithium-ion battery diaphragm with high strength and low shrinkage, comprising the following steps:

[0026] Step 1: High molecular weight polyethylene (VH150U / VH035, Daehan Petrochemical Co., Ltd.), calcium sulfate whiskers (SXY-S-011 Sinopec), rare earth coupling agent (DN-9311, Nanjing Daoning Chemical Co., Ltd. company) and paraffin oil (Zhejiang Zhengxin Petroleum Technology Co., Ltd.) were added to the stirring tank according to the mass-to-number ratio of 25:2:1:72, and mixed at 80°C to obtain a mixture;

[0027] Among them, the weight-average molecular weight of high molecular weight polyethylene is 600,000, and the average aspect ratio of the whiskers of calcium sulfate whiskers is 20-40;

[0028] Step 2: extruding the obtained mixture through a twin-screw extruder to form a homogeneous blend;

[0029] Wherein, the temperature of the twin-screw extruder is 190° C., and the screw speed is 60 rpm;

[0030] Step 3: cooling and shaping t...

Embodiment 2

[0045] A preparation method of a lithium-ion battery diaphragm with high strength and low shrinkage, comprising the following steps:

[0046] Step 1: Add high molecular weight polyethylene, calcium sulfate whiskers, rare earth coupling agent and paraffin oil into the mixing tank according to the ratio of parts by mass of 25:3:2:70, and mix at 80°C to obtain a mixture;

[0047] Wherein, the weight-average molecular weight of high molecular weight polyethylene is 1 million, and the whisker average aspect ratio of calcium sulfate whisker is 20-40;

[0048] Step 2: extruding the obtained mixture through a twin-screw extruder to form a homogeneous blend;

[0049] Wherein, the temperature of the twin-screw extruder is 195° C., and the screw speed is 68 rpm;

[0050] Step 3: cooling and shaping the obtained homogeneous blend through cooling and shaping rollers to obtain cast sheets;

[0051] The temperature of the cooling and setting roller is 18°C, and the speed of the cooling and...

Embodiment 3

[0065] A preparation method of a lithium-ion battery diaphragm with high strength and low shrinkage, comprising the following steps:

[0066] Step 1: Add high molecular weight polyethylene, calcium sulfate whiskers, rare earth coupling agent and paraffin oil into the mixing tank according to the ratio of parts by mass of 26:4:2:68, and mix at 80°C to obtain a mixture;

[0067] Wherein, the weight-average molecular weight of high-molecular-weight polyethylene is 1.2 million, and the average aspect ratio of the whiskers of calcium sulfate whiskers is 20-40;

[0068] Step 2: extruding the obtained mixture through a twin-screw extruder to form a homogeneous blend;

[0069] Wherein, the temperature of the twin-screw extruder is 205° C., and the screw speed is 70 rpm;

[0070] Step 3: cooling and shaping the obtained homogeneous blend through cooling and shaping rollers to obtain cast sheets;

[0071] The temperature of the cooling and setting roller is 15°C, and the speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com