Road guardrail reinforcing device and reinforcing method thereof

A reinforcement device and road guardrail technology, which is applied to road safety devices, roads, roads, etc., can solve problems such as inability to maintain, insufficient strength of the buried deep part of the column, corrosion, etc., so as to make up for the lack of anti-collision ability and prevent vehicles from rushing out of the guardrail , Enhance the effect of anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

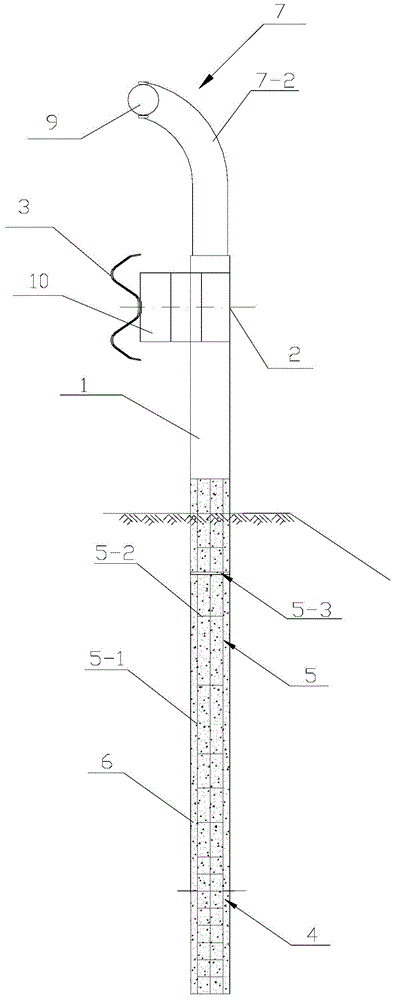

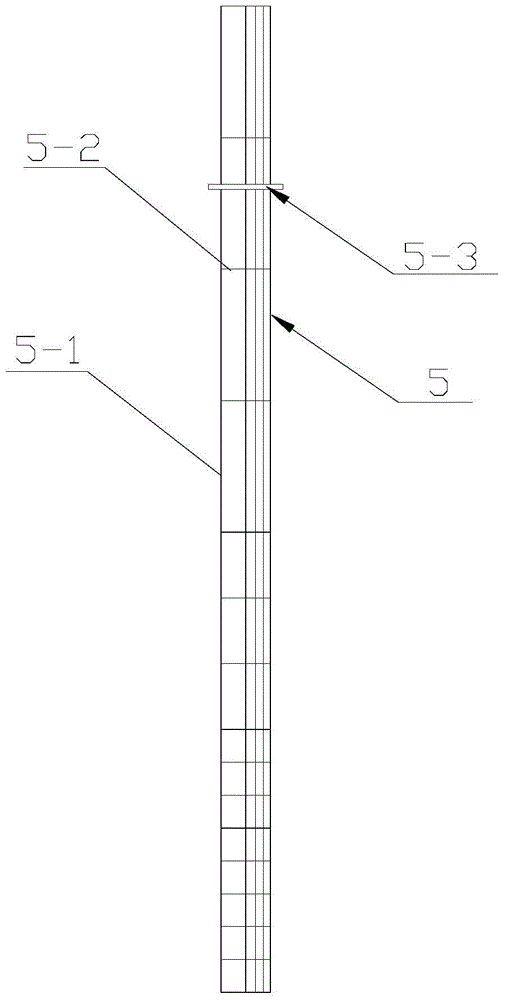

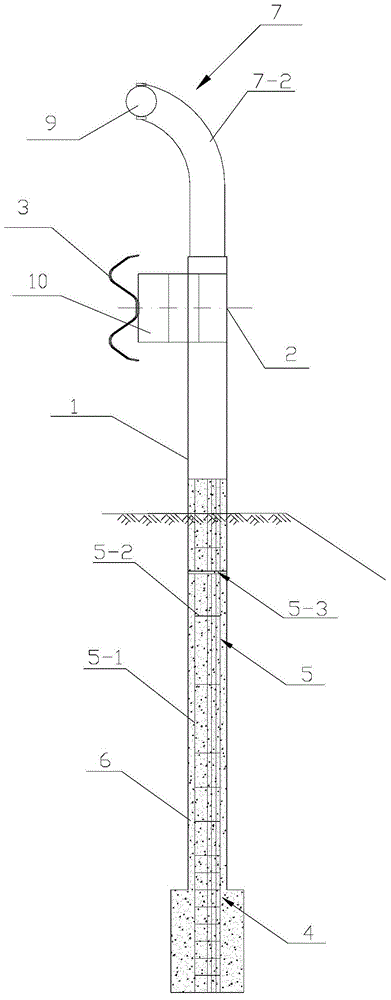

[0035] see figure 1 and figure 2 , a highway guardrail reinforcement device, including a hollow foundation guardrail post 1 embedded on the foundation outside the expressway, the so-called basic guardrail post can be considered as an old guardrail post, or a new guardrail post; it is installed through a fastener 2 On the corrugated guardrail plate 3 on the side of the guardrail column on the highway, a reinforcement hole 4 is drilled toward the foundation along the center of the hollow foundation guardrail column. The depth of the reinforcement hole is 100 mm to 600 mm from the bottom section of the guardrail column; Arrange a reinforcement cage 5, the reinforcement cage is filled with concrete blocks 6, the longitudinal height of the rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com