A broadband piston compressor

A compressor and piston technology, applied in the field of compressors, can solve the problems of unstable low-frequency drive, increased cooling output, increased electromagnetic noise of aerodynamic noise motors, etc., achieving obvious noise reduction effect, reducing speed fluctuations, and improving low-frequency efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

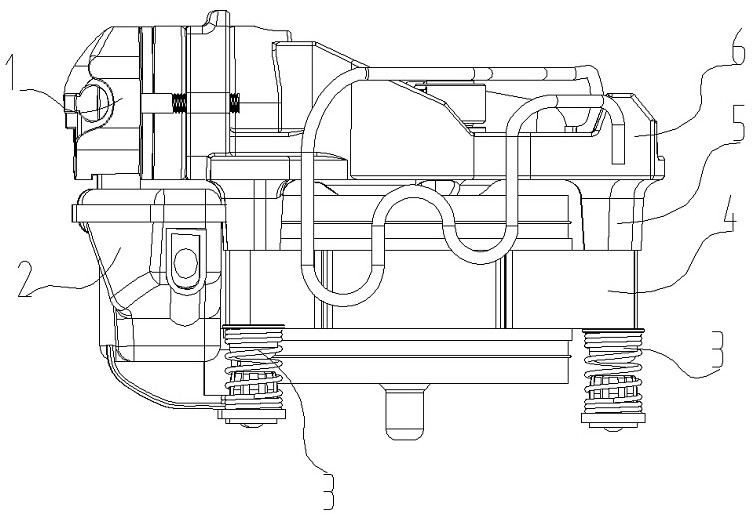

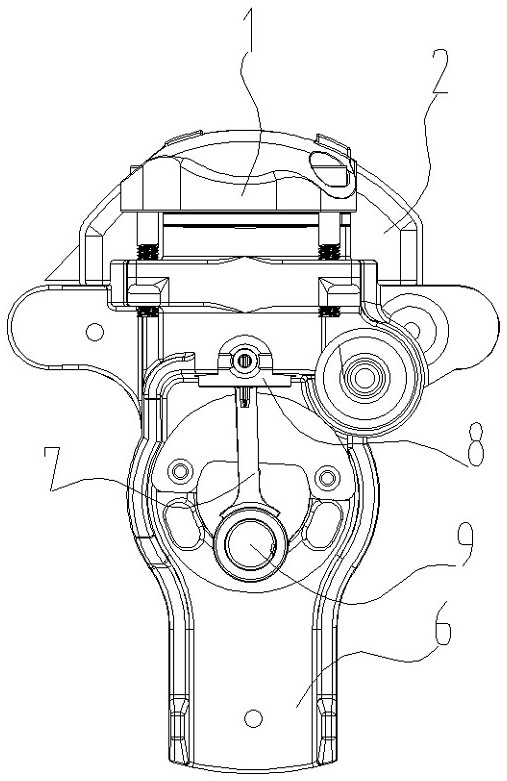

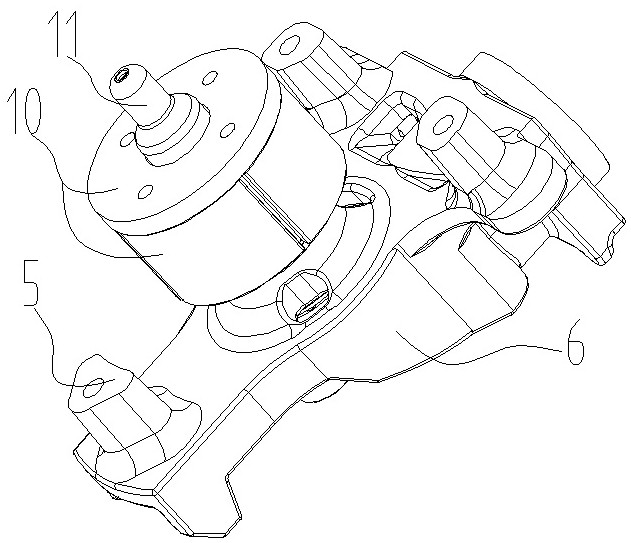

[0025] This embodiment provides a broadband piston compressor, such as figure 1 As shown, the wide-band piston compressor includes a cylinder head assembly 1, a muffler 2, a bolt 3, a stator iron core 4, a frame mounting foot 5 and a frame 6, wherein the stator iron core 4 is arranged on the frame 6 through the bolt 3. The frame is mounted on the feet 5 so that the stator core 4 is fixed with the frame 6 . The piston and connecting rod of the broadband piston compressor are as figure 2 As shown, the piston 8 is connected with the connecting rod 7 through a pin, and the connecting rod 7 is sleeved on the crankshaft 9. The crankshaft 9 is driven by the rotor to make a circular motion and the connecting rod 7 drives the piston 8 to reciprocate to compress the gas. The rotor components of the broadband piston compressor are as image 3 As shown, the rotor assembly 10 is installed on the pump body structure, the oil pump 11 is sleeved on one end of the crankshaft 9, the rotor as...

Embodiment 2

[0030] This embodiment provides a broadband piston compressor, and the structure of the broadband piston compressor is the same as that of the broadband piston compressor in Embodiment 1. In the broadband piston compressor provided in this embodiment, the ratio of the moment of inertia J of the rotor assembly 10 to the total mass M of the connecting rod 7 and the piston 8 is: J / M=0.116. The noise test of the broadband piston compressor provided in this embodiment and the existing piston compressor, the results are as follows Figure 4 shown, Figure 4 The line segment A marked in is the noise test result of the existing piston compressor, Figure 4 The B line segment marked in the noise test result of the broadband piston compressor provided in this embodiment. Compared with the existing piston compressor, the broadband piston compressor provided by this embodiment can reduce the torque fluctuation by adjusting the value of J / M, effectively improve the motor efficiency, and ...

Embodiment 3

[0035] This embodiment provides a broadband piston compressor, the maximum operating frequency of the broadband piston compressor exceeds 100 Hz, the components and structure of the broadband piston compressor are the same as the existing piston compressor, compared with the existing piston compressor The wide-band piston compressor is also provided with a compressor suction valve plate.

[0036] The ratio of the moment of inertia J of the rotor assembly 10 of the broadband piston compressor to the total mass M of the connecting rod 7 and the piston 8 is: 0.16>J / M>0.08, and simultaneously satisfies the moment of inertia J of the rotor assembly 10 and the broadband piston compressor The ratio of the stiffness A of the compressor suction valve sheet is: 0.0038>J / A>0.0024, where the unit of the stiffness A of the compressor suction valve sheet is N / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com