Rotor inertia type anti-side-rolling-force vibration absorber for railway vehicle

A technology for dynamic vibration absorbers and rail vehicles, applied in inertia force compensation, shock absorbers, non-rotational vibration suppression, etc., can solve problems affecting the safety and stability of train operation, increase the risk of train overturning, etc. Ease of performance, control method, and the effect of improving running stability and ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

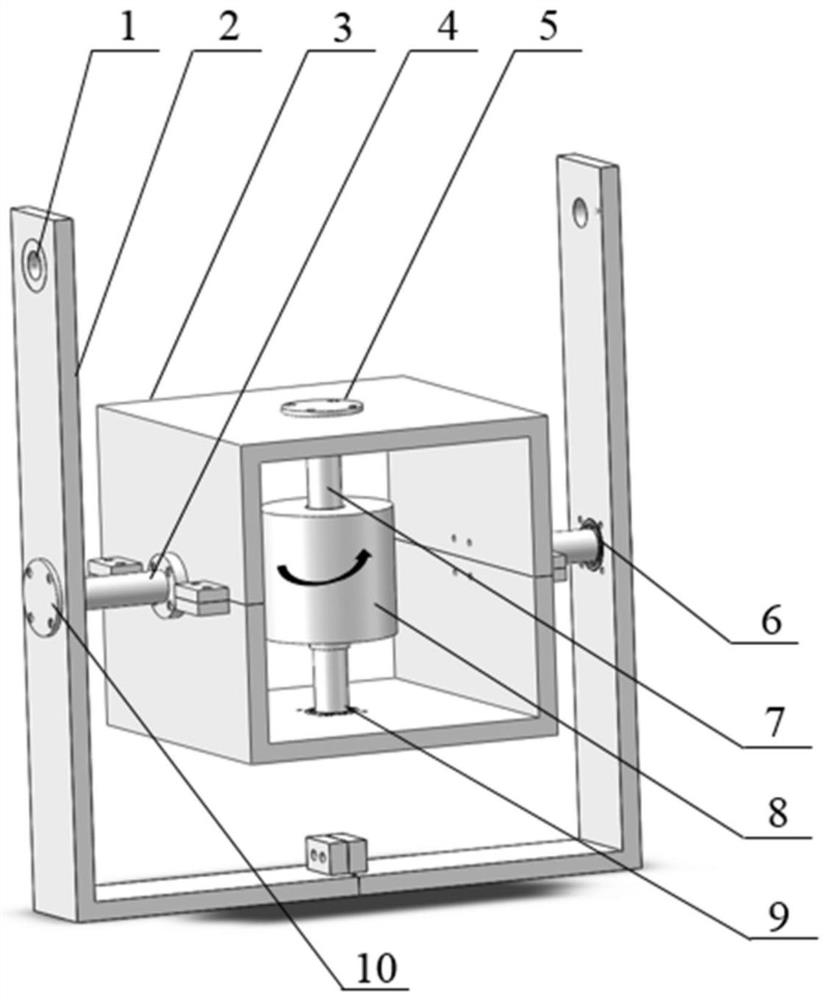

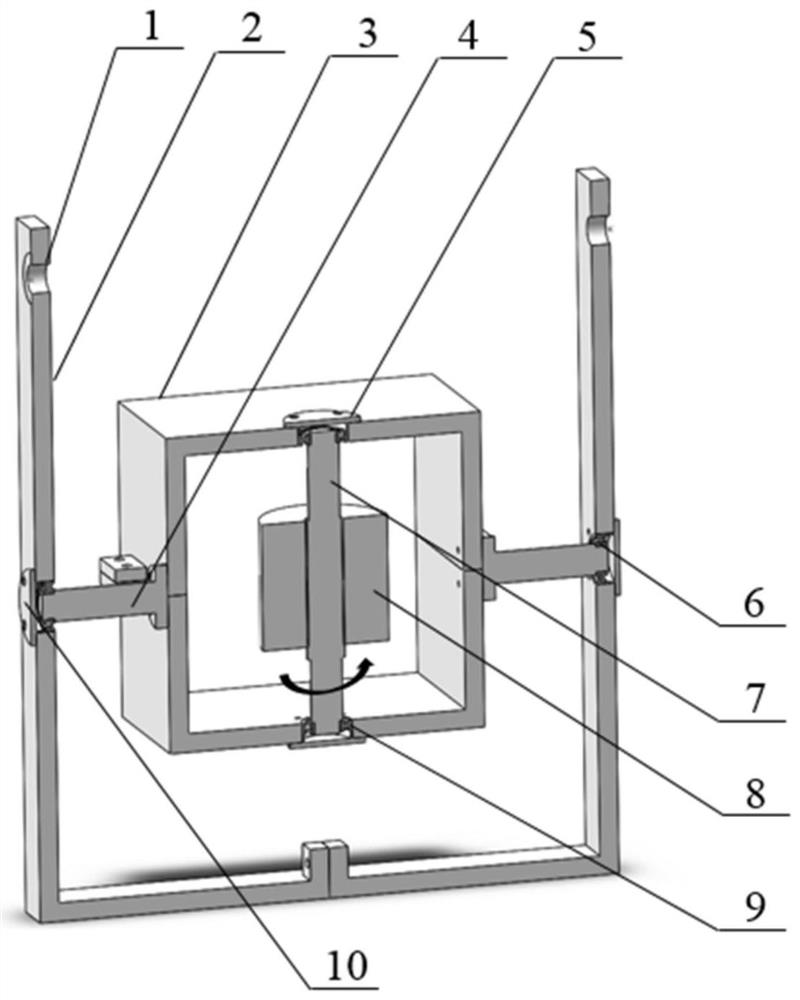

[0045] Such as figure 1 and figure 2 As shown, the present invention provides a rotor inertia type anti-rolling shock absorber for rail vehicles. For the installation on the above, the carrier frame 2 is U-shaped by two "L" beams connected by bolts, and connected with the underframe of the car body through the lifting hole 1; the rotor unit includes the rotor shaft 7 and the rotor mass 8, and the rotor unit can pass through Connecting electricity to realize rotation drive; the rotor mass 8 is a cylindrical structure with a through hole in the middle;

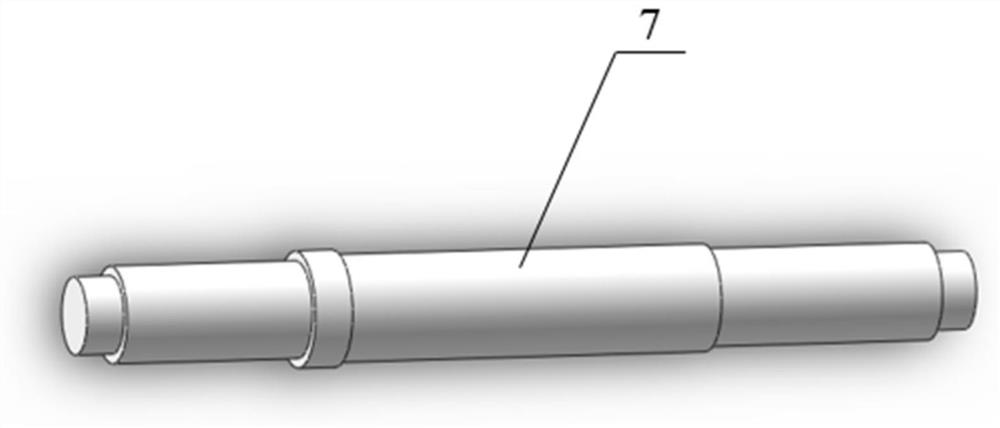

[0046] Such as image 3 As shown, the rotor shaft 7 is a stepped shaft structure; the rotor mass 8 and the rotor shaft 7 are interference fit to ensure that there is no relative rotation between them, and a rotor is arranged between the two ends of the rotor shaft 7 and the balance frame 3 Shaft bearing 9, the outer ring of the rotor shaft bearing 9 is fixed with the balance frame 3, so that the rotor unit can rotate relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com