Method for inhibiting mining damage depth based on clay-based slurry advanced grouting modified bottom plate hard rock

A technology of advanced grouting and mining damage, applied in earth-moving drilling, ground mining, mining equipment, etc., can solve problems such as the depth or range of floor damage, and achieve the effect of inhibiting or reducing the depth or range of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

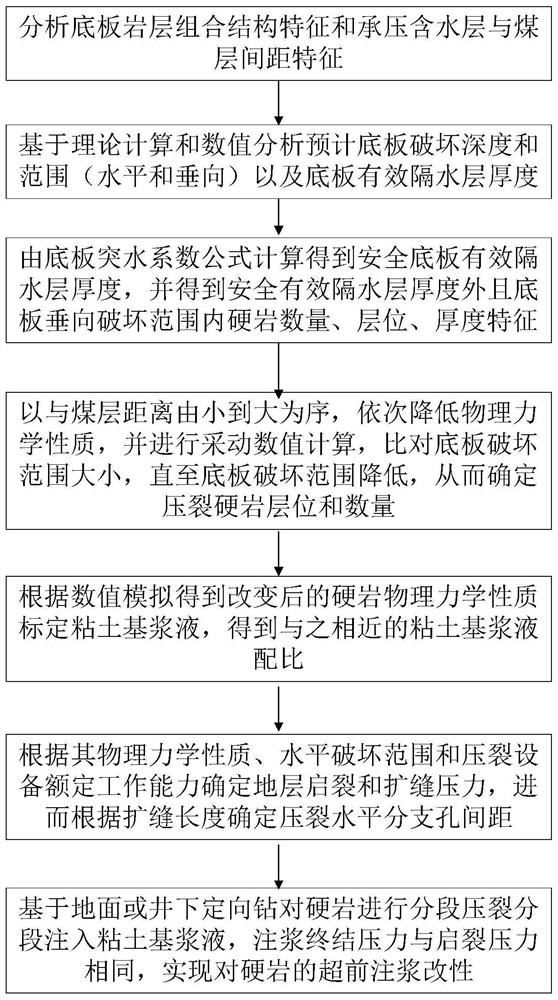

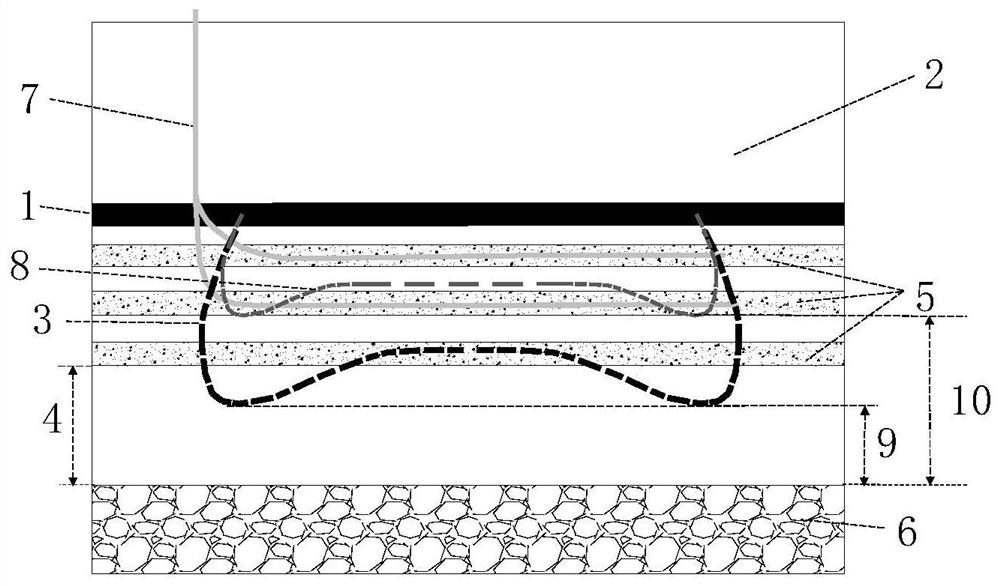

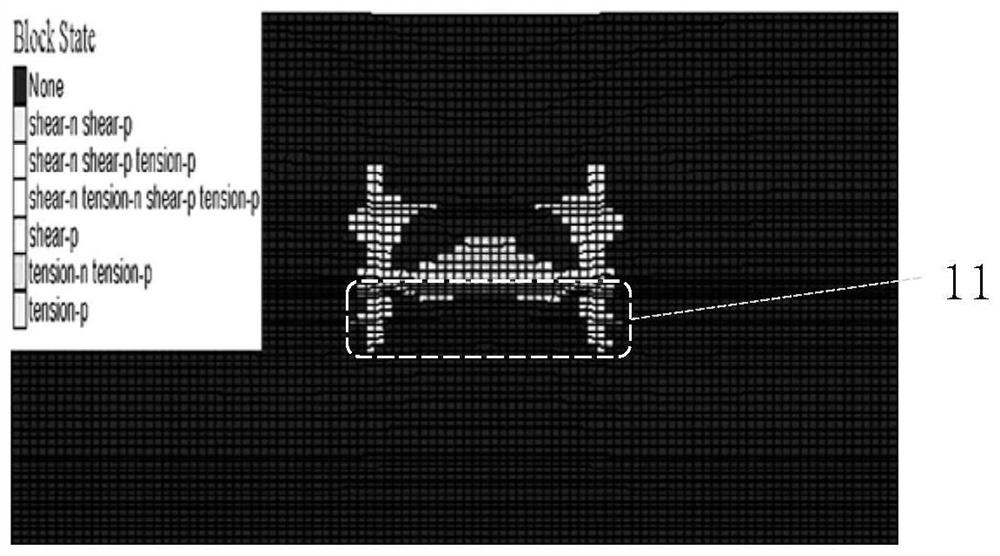

[0045] see figure 1 , figure 2 with image 3 , shows the method of the present invention based on the advance grouting of clay-based grout to modify the bottom plate to suppress the mining damage depth.

[0046] The method for suppressing mining failure depth based on clay-based grout advanced grouting modified floor hard rock comprises the following steps:

[0047] Step 1: Analyze and determine the damage range and depth of the mining floor and the thickness of the effective water-resisting layer of the floor before the fracturing grouting modification.

[0048] According to the geological and hydrogeological data, combined with the columnar drilling, the lithology, thickness and combination structure characteristics of the floor strata were analyzed, and the spatial distribution of the distance between the confined aquifer 6 and the coal seam 1 was obtained according to the occurrence characteristics of the confined aquifer 6 below the working face feature.

[0049] Due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com