Green colistin extraction method

A colistin and green technology, applied in the field of medicine, can solve the problems of high cost of sewage treatment, high environmental pollution, long process, etc., and achieve the effects of low cost of sewage treatment, short process and less waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

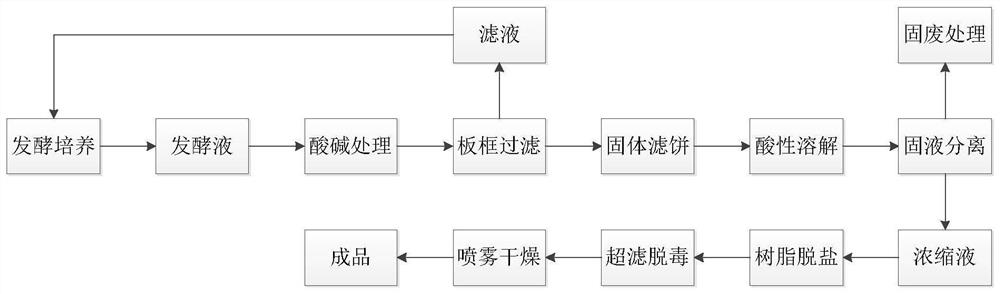

Method used

Image

Examples

Embodiment 1

[0024]The potency of the fermentation broth is 645,000 u / mL, heated to 70℃, acidified to 1.8 with oxalic acid, stirred for 30 minutes, then added calcium hydroxide to adjust the pH value to 9.5, stirred for 30 minutes, precipitation occurs, filter with a plate and frame, and save the filtrate for next Batch fermentation water; add the solid filter cake to the sulfuric acid solution of 1 / 10 volume of the fermentation broth, stir to dissolve, and dissolve the pH value of 6.2; add activated carbon and purifying agent to the dissolving solution, filter through the plate and frame to obtain the colistin concentrate; concentrate After resin desalination, ultrafiltration to remove endotoxin, and finally spray-dried to obtain the finished product.

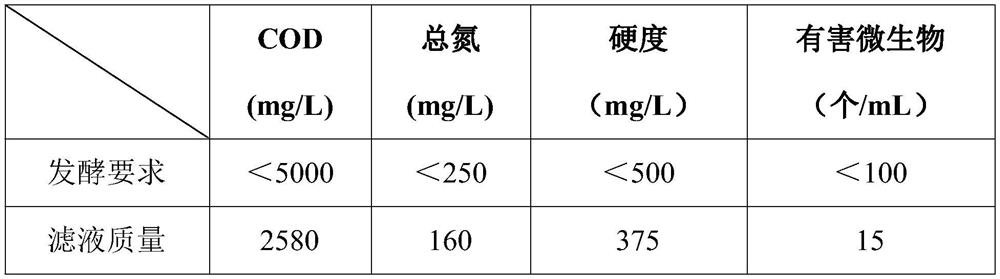

[0025]The filtrate is used as the next batch of fermentation water. The quality of the test is shown in Table 1:

[0026]

Embodiment 2

[0028]The filtrate in Example 1 was adjusted to pH 7.0 and used as fermentation water for fermentation. The pot had a potency of 647,000 u / mL. It was diluted with the ultrafiltration retentate in Example 1, heated to 45°C, and acidified by adding oxalic acid. To 1.6, stir for 30 minutes, then add calcium oxide to adjust the pH to 10.5, stir for 30 minutes, precipitation occurs, filter with a plate and frame, and reserve the filtrate as the next batch of fermentation water; add the solid filter cake to the sulfuric acid solution of 1 / 15 volume of the fermentation broth, Stir and dissolve to dissolve the pH value of 5.7; add activated carbon and purifying agent to the dissolving solution, and filter through plate and frame to obtain a colistin concentrate; the concentrate is desalinated by resin, ultrafiltration to remove endotoxin, and finally spray dried to obtain a finished product.

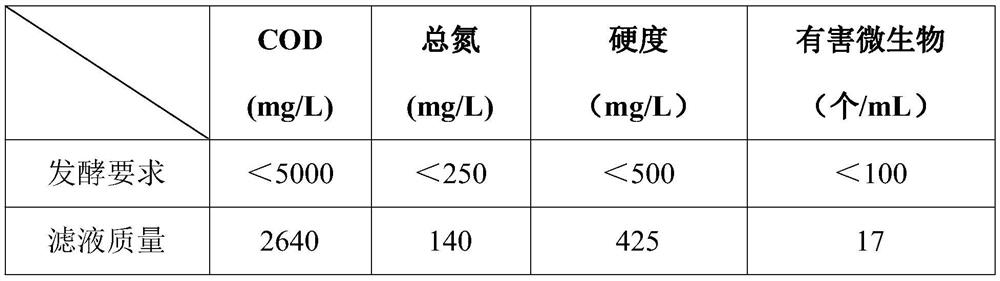

[0029]The filtrate is used as the next batch of fermentation water, and the tested quality is shown i...

Embodiment 3

[0032]The filtrate in Example 2 was adjusted to pH 6.0 and used as fermentation water for fermentation. The pot had a potency of 643,000 u / mL. It was diluted with the ultrafiltration retentate in Example 2, heated to 60°C, and acidified by adding phosphoric acid. To 2.0, stir for 30 minutes, then add calcium hydroxide to adjust the pH to 11.0, stir for 30 minutes, precipitation occurs, filter with a plate and frame, and reserve the filtrate as the next batch of fermentation water; add the solid filter cake to the sulfuric acid solution of 1 / 12 volume of the fermentation broth , Stir and dissolve to dissolve the pH value of 6.0; add activated carbon and purification agent to the dissolving solution, and filter through plate and frame to obtain a colistin concentrate; the concentrate is desalted by resin, ultrafiltration to remove endotoxin, and finally spray-dried to obtain the finished product.

[0033]The filtrate is used as the next batch of fermentation water, and the quality of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com