Preparation method of epoxy compound

A technology of epoxy compounds and compounds, applied in the direction of organic chemistry, etc., can solve the problems of oxidant and product decomposition, reduced selectivity of epoxidized products, large reaction heat, etc., achieve high conversion rate, improve process safety, and improve selectivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0056] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

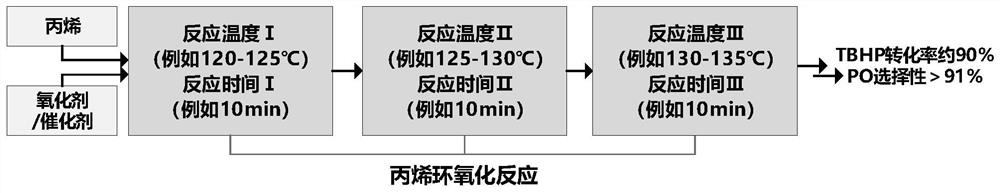

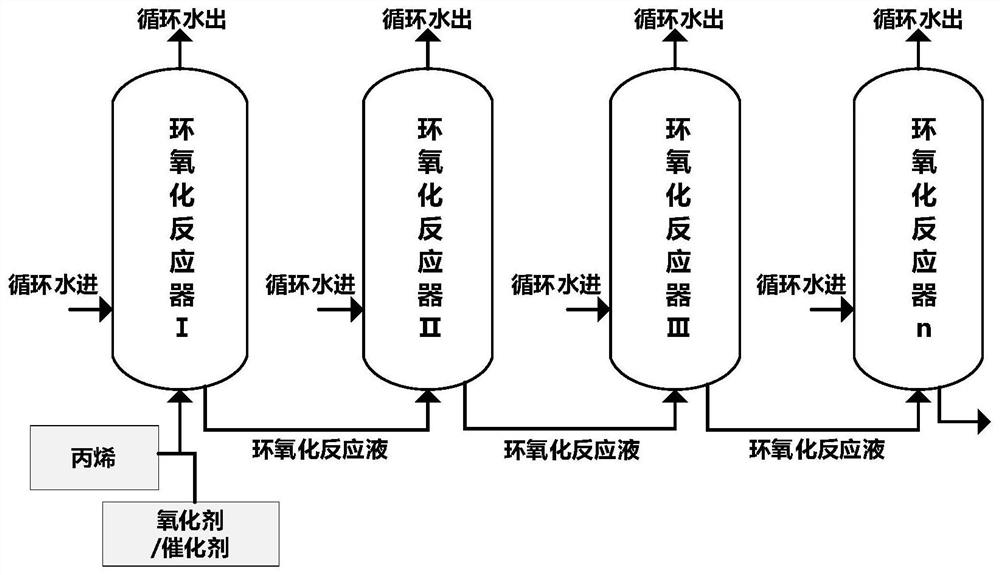

[0057] The schematic diagram of the epoxidation reaction device used in the following examples and comparative examples is as follows figure 2 As shown, each reactor represents a 1st order reaction. According to the flow direction of the reaction...

Embodiment 1

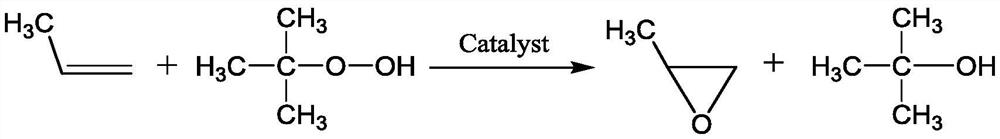

[0059] Using tert-butyl alcohol as a solvent, the concentration of oxidant tert-butyl hydroperoxide is 20wt%, the molar ratio of propylene to tert-butyl hydroperoxide is 3:1, and the concentration of molybdenum polyol catalyst is 300ppm.

[0060] Put the above materials in the figure 2 Mix well in the epoxidation reaction device shown, carry out the propylene epoxidation reaction at 120-125°C within the reaction residence time of 0-10 minutes, and carry out the propylene epoxidation reaction at 125-130°C and higher than the reaction residence time of 10-20 minutes The propylene epoxidation reaction is carried out at the temperature of the previous stage, and the propylene epoxidation reaction is carried out at a temperature of 130-135° C. and higher than the reaction temperature of the previous stage within the reaction residence time of 20-30 minutes.

[0061] After the 30-minute reaction in the first stage, the product propylene oxide was separated by rectification, and the...

Embodiment 2

[0086] Using tert-butyl alcohol as a solvent, the concentration of oxidant tert-butyl hydroperoxide is 20wt%, the molar ratio of 1-butene to tert-butyl hydroperoxide is 3:1, and the concentration of molybdenum polyol catalyst is 300ppm.

[0087]Mix the above materials evenly in the epoxidation reaction device, carry out the 1-butene epoxidation reaction at 120-125°C within the reaction residence time of 0-10 minutes, and carry out the 1-butene epoxidation reaction at 125-130°C within the reaction residence time of 10-20 minutes The 1-butene epoxidation reaction is carried out at a temperature higher than that of the previous paragraph, and the 1-butene epoxidation reaction is carried out at a temperature of 130-135° C. and higher than that of the previous paragraph within the reaction residence time of 20-30 minutes.

[0088] After the 30-minute reaction in the first stage, the product 1,2-epoxybutane was separated by rectification, and then a part of the by-product tert-butano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com