Manufacturing process of super-wear-resistant sound-absorbing soft floor

A manufacturing process, ultra-wear-resistant technology, applied in the manufacture of tools, wooden veneer joints, flat products, etc., can solve the problems of glue opening and deformation impact resistance, poor sound insulation effect, high production cost, etc., to achieve anti-glue opening Deformation, saving process, avoiding the effects of glue opening and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

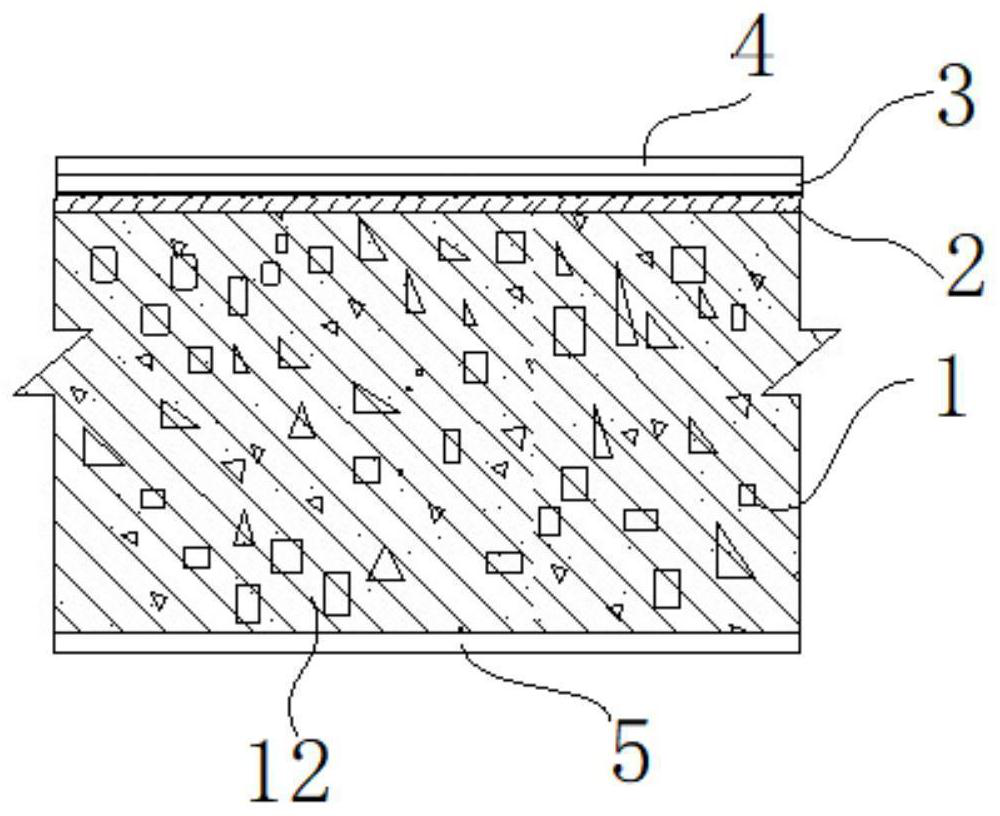

[0039] Such as figure 1 As shown, the manufacturing process of the super wear-resistant and sound-absorbing soft floor in this embodiment, the steps are:

[0040] S1. Mixing materials: mix straw section 12, glue, additives and other components; additives include acrylamide (ACR), stabilizer calcium zinc composite heat stabilizer, PE wax, SP60 hard acid, plasticizer , carbon black, paraffin wax, etc., and other components include calcium powder, green powder, polyvinyl chloride, recycled materials and resin powder, etc., accounting for 60% by weight. The weight ratio of straw segment 12 and glue solution in the components is respectively 10-20% and 8-12%, preferably 20% and 10% respectively; others are various additives; recycled material refers to the leftovers in the process of board making, which can be recycled; green powder is used on the body of bottled drinking water The powder made by grinding the packaging label film, the main component is polyvinyl chloride, which is...

Embodiment 2

[0049] The production process of the ultra-wear-resistant and sound-absorbing soft floor in this embodiment is further improved on the basis of Embodiment 1. In step S1, the straw segment 12 is first mixed with the glue, and then the additives and other components are mixed in order. uniform. The segmented straw and the glue are mixed first, so that the glue can be temporarily stored in the hollow structure of the straw section 12, especially the wheat straw, which has a larger hollow volume, and the glue adheres to the hollow core due to its viscosity. In the structure, the temporary storage capacity of the glue can be more, so that the slow-release effect of the glue is better in the later roll forming and pressing of the press.

[0050] After testing, the super wear-resistant and sound-absorbing soft floor prepared in this example has a tensile bond strength between layers ≥ 0.3 MPa; impact resistance ≥ 15J; wear-resistant rotation speed ≥ 9900 revolutions, "GB / T 18102-2007...

Embodiment 3

[0052] The manufacturing process of the super wear-resistant, super wear-resistant and sound-absorbing soft floor of this embodiment is further improved on the basis of embodiment 2. The pressing roller in the pressing roller unit is a hot pressing roller; the pressing machine is a hot pressing machine, It can keep the glue at a certain high temperature to improve its fluidity, improve the slow-release effect, and avoid sticking to the roller as much as possible. The temperature of the press and the pressure roller is 130-150°C, and the fluidity of the glue is better in this temperature range; the pressure of the press is 100-130bar, and the pressing time is 10-20min, according to the thickness of each layer of the board. Adjust accordingly.

[0053] After testing, the ultra-wear-resistant and sound-absorbing soft floor prepared in this example has a tensile bond strength between layers ≥ 0.35MPa; impact resistance ≥ 18J; wear-resistant rotation speed ≥ 9900 revolutions, "GB / T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com