Mixer capable of improving ozone dissolution efficiency and electrolytic ozone medical waterway sterilizer

A mixer and sterilizer technology, applied in mixers, fluid mixers, dissolving and other directions, can solve problems such as easy breeding of bacteria, slow water flow, and pathogenic microorganism infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

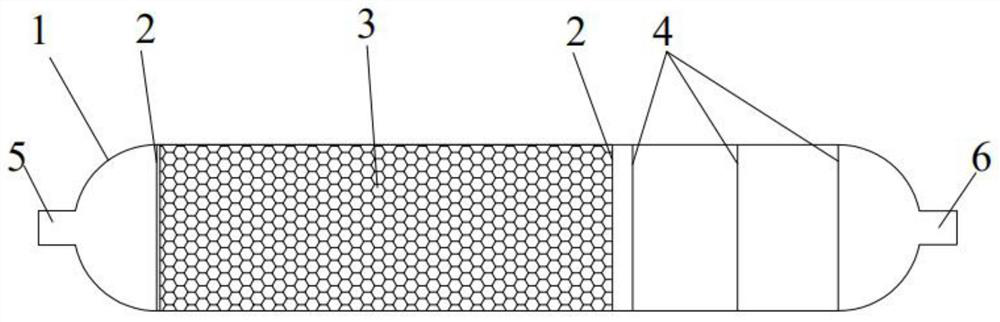

[0028] Such as figure 1 As shown, this embodiment provides a mixer for improving ozone dissolution efficiency, including a housing 1, a screen 2, a contact filler 3 and a microporous screen 4, and the two ends of the housing 1 are respectively provided with a mixer water inlet 5 and a mixer Water outlet 6, two net plates 2 and at least one microporous net plate 4 are sequentially arranged on the inner wall of the shell 1 along the direction from the mixer water inlet 5 to the mixer water outlet 6, and the inside of the shell 1 between the two net plates 2 Filled with contact filler 3 , the aperture on the microporous screen 4 is smaller than the aperture on the screen 2 .

[0029] The mixed fluid of ozone and water enters from the water inlet 5 of the mixer. Under the action of the mesh plate 1, the large air bubbles are initially divided into small air bubbles, and under the action of the contact filler 3, the contact area between ozone and water is increased to improve The ...

Embodiment 2

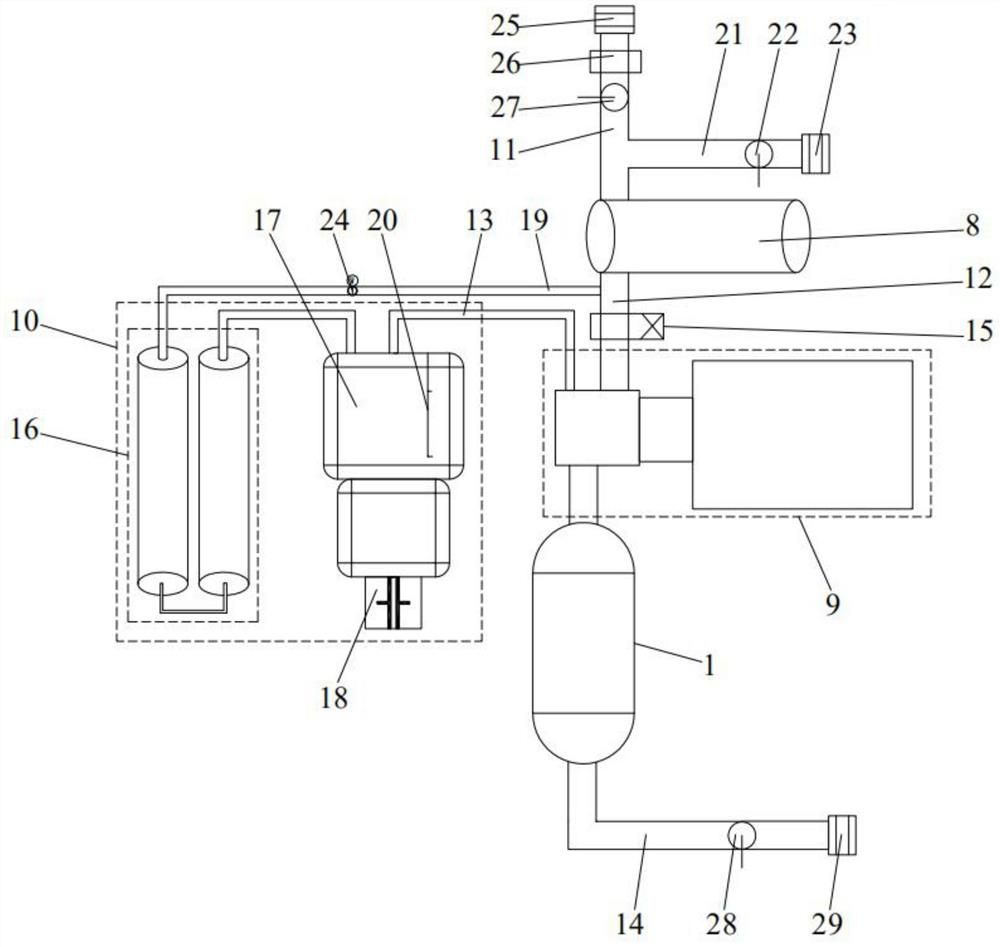

[0032] Such as Figure 2~4As shown, the present embodiment provides an electrolytic ozone medical waterway disinfection machine, including the mixer for improving the ozone dissolution efficiency in Embodiment 1, and also including a cabinet 7 and a pre-filter 8 fixedly arranged in the cabinet 1, a gas Liquid mixing device 9 and electrolytic ozone generator 10, one end of the pre-filter 8 is connected to the water inlet pipe 11, and the water inlet pipe 11 is used to pass into tap water, and the other end of the pre-filter 8 is mixed with gas and liquid through the filtered water outlet pipe 12 The water inlet of the device 9 is connected, the ozone outlet pipe 13 of the electrolytic ozone generator 10 is connected with the air inlet of the gas-liquid mixing device 9, the water outlet of the gas-liquid mixing device 9 is connected with the water inlet 5 of the mixer through a pipeline, and the water outlet of the mixer 6 is connected with the disinfection outlet pipe 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com