Microbial fuel cell cathode catalyst CaFe1-XCuXO3 as well as preparation method and application thereof

A fuel cell cathode and microbial technology, applied in the field of bioelectrochemistry, can solve the problems of poor efficiency and stability, high cost, and low output power, and achieve the effects of stable output, low cost, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

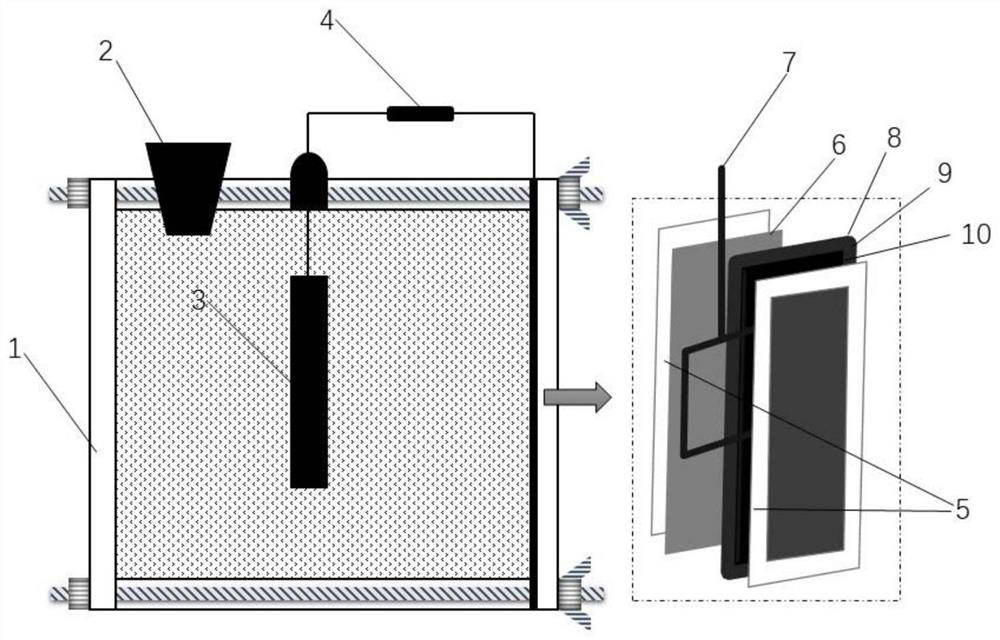

[0040] The present invention CaFe 0.9 Cu 0.1 o 3 An embodiment of the catalyst, the reactor of the microbial fuel cell described in this embodiment is as figure 1 As shown: No. 1 is marked as the plastic shell of the reactor, one side is open, and the rest are sealed; No. 2 is marked as the rubber plug of the liquid change port; No. 3 is marked as the anode carbon felt, soaked in the anolyte; No. 4 is marked Resistor (1000Ω) connecting the anode and cathode, the connecting wire is polished titanium wire; No. 5 is marked as a rubber gasket; No. 6 is marked as a PEM film; No. 7 is marked as a conductive metal coil connecting the resistance; No. 8 is marked as containing CaFe 0.9 Cu 0.1 o 3 The catalytic layer of the catalyst; No. 9 is marked as the carbon cloth cathode; No. 10 is marked as the carbon base layer.

[0041] Cathode Catalyst for Microbial Fuel Cells 0.9 Cu 0.1 o 3 , the preparation process is as follows:

Embodiment 2

[0056] The structure of this embodiment and the preparation method of carbon cloth are exactly the same as those in Example 1, except that the catalyst preparation method is different, and its preparation method is as follows:

[0057] (1) Mix calcium acetate monohydrate, iron nitrate nonahydrate, ethylenediaminetetraacetic acid and citric acid, according to the ratio of the amount of substances: calcium acetate monohydrate: iron nitrate nonahydrate: ethylenediaminetetraacetic acid: citric acid =1:1:2:4, add deionized water and stir to obtain a mixed solution;

[0058] (2) Heating and stirring the mixed solution in step (1), the stirring rate is 400 rpm, the heating temperature is 95°C, ammonia water is added dropwise during the heating and stirring process, and the sol is obtained after 5 hours;

[0059] (3) Place the sol in step (2) in a tube furnace at 200°C and keep it warm for 7 hours to obtain a solid, which is ground into powder;

[0060] (4) Take the powder in step (3...

Embodiment 3

[0063] The structure of this embodiment and the preparation method of carbon cloth are exactly the same as those in Example 1, except that the catalyst preparation method is different, and its preparation method is as follows:

[0064] (1) Calcium acetate monohydrate, ferric nitrate nonahydrate, copper nitrate trihydrate, ethylenediaminetetraacetic acid and citric acid are mixed, and the ratio according to the amount of substances is: calcium acetate monohydrate: iron nitrate nonahydrate: nitric acid trihydrate Copper: ethylenediaminetetraacetic acid: citric acid = 1:0.7:0.3:2:4, add deionized water and stir to obtain a mixed solution;

[0065] (2) Heating and stirring the mixed solution in step (1), the stirring rate is 600 rpm, the heating temperature is 105°C, ammonia water is added dropwise during the heating and stirring process, and the sol is obtained after 7 hours;

[0066] (3) Place the sol in step (2) in a tube furnace at 300°C and keep it warm for 9 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com