Antirust corrosion-resistant rosin phenolic resin paint and preparation method thereof

A technology of rosin phenolic resin and phenolic resin, which is applied in the field of anti-rust and anti-corrosion rosin phenolic resin paint and its preparation, can solve the problems of poor corrosion resistance and anti-rust performance, poor water resistance and impermeability of oil-based paint, etc., to achieve Improvement of anti-rust and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preferably, the preparation method of the α-zirconium phosphate nanoplate modified by nitrile group comprises the following steps:

[0050] S1. Prepare a methylamine solution with a concentration of 0.2mol / L, weigh quantitative α-zirconium phosphate, disperse it in deionized water at a solid-to-liquid ratio of 100mL / g, and add the methylamine solution dropwise to the α-zirconium phosphate In the aqueous solution, wherein the molar ratio of the amount of methylamine added to the α-zirconium phosphate is 2.5:1, 300W ultrasound for 5 to 8 minutes after the decrease is completed for preliminary dispersion, and the precipitate is filtered out, and deionized water and N, N - washing with dimethylformamide to obtain product A;

[0051] S2. Disperse the product A in N,N-dimethylformamide at a solid-to-liquid ratio of 50 mL / g, and add dicyandiamide, the amount of which is 4.8% of the mass of α-zirconium phosphate, The temperature of the solution was raised to 80°C, and the reac...

Embodiment 1

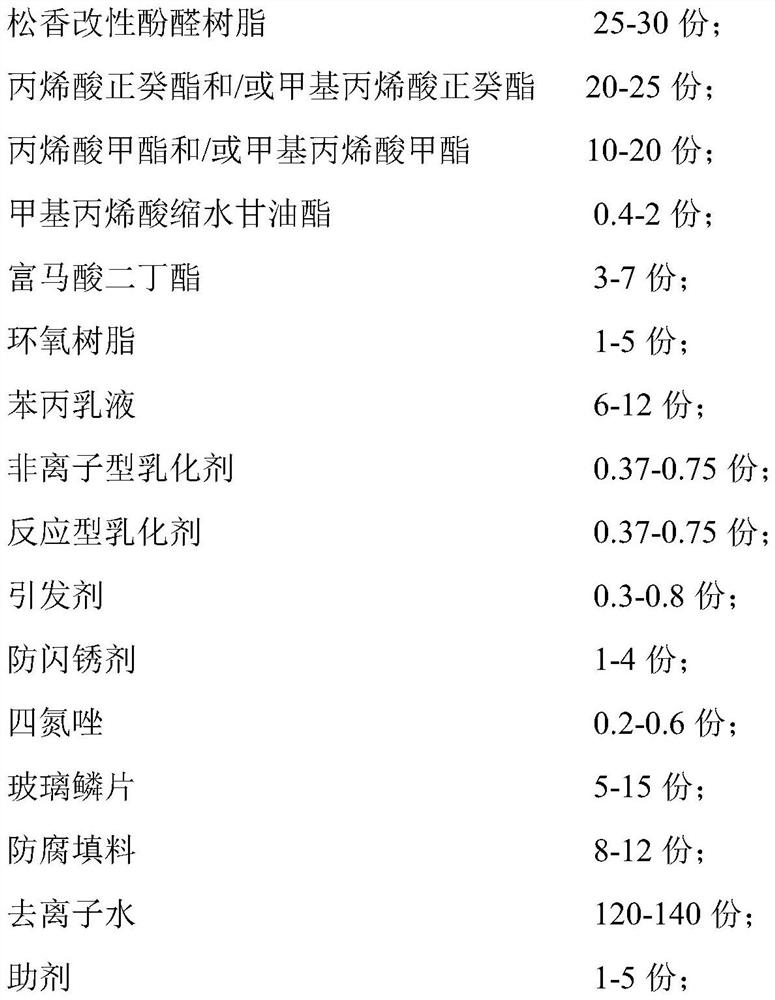

[0069] A kind of anti-rust anti-corrosion rosin phenolic resin paint, has the component composition of following weight:

[0070]

[0071] Wherein, the anti-corrosion filler is α-zirconium phosphate nanosheets modified by cyanoguanidine;

[0072] Described epoxy resin is glycidyl ether epoxy resin;

[0073] The nonionic emulsifier is an APEO type nonionic emulsifier; the reactive emulsifier is 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ammonium ether sulfate;

[0074] Described initiator is ammonium persulfate or potassium persulfate;

[0075] The anti-flash rust agent is organic zinc chelate or nitrite;

[0076] Described auxiliary agent is dispersant, defoamer and leveling agent;

[0077] The preparation method of the α-zirconium phosphate nanosheet modified by the nitrile group comprises the following steps:

[0078] S1. Prepare a methylamine solution with a concentration of 0.2mol / L, weigh quantitative α-zirconium phosphate, disperse it in deioniz...

Embodiment 2

[0086] A kind of anti-rust anti-corrosion rosin phenolic resin paint, has the component composition of following weight:

[0087]

[0088]

[0089] Wherein, the anti-corrosion filler is α-zirconium phosphate nanosheets modified by cyanoguanidine;

[0090] Described epoxy resin is glycidyl ether epoxy resin;

[0091] The nonionic emulsifier is an APEO type nonionic emulsifier; the reactive emulsifier is 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ammonium ether sulfate;

[0092] Described initiator is ammonium persulfate or potassium persulfate;

[0093] The anti-flash rust agent is organic zinc chelate or nitrite;

[0094] Described auxiliary agent is dispersant, defoamer and leveling agent;

[0095] The preparation method of the α-zirconium phosphate nanosheet modified by the nitrile group comprises the following steps:

[0096] S1. Prepare a methylamine solution with a concentration of 0.2mol / L, weigh quantitative α-zirconium phosphate, disperse i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com