Composite nano-montmorillonite complex modified epoxy anti-rust powder coating for automotive chassis and preparation method of composite nano-montmorillonite complex modified epoxy anti-rust powder coating

A technology of nano-montmorillonite and powder coatings, applied in powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of high construction equipment requirements, short protection period, high curing temperature, etc., to improve the anti-rust and anti-corrosion capabilities , excellent protection ability, and the effect of improving anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

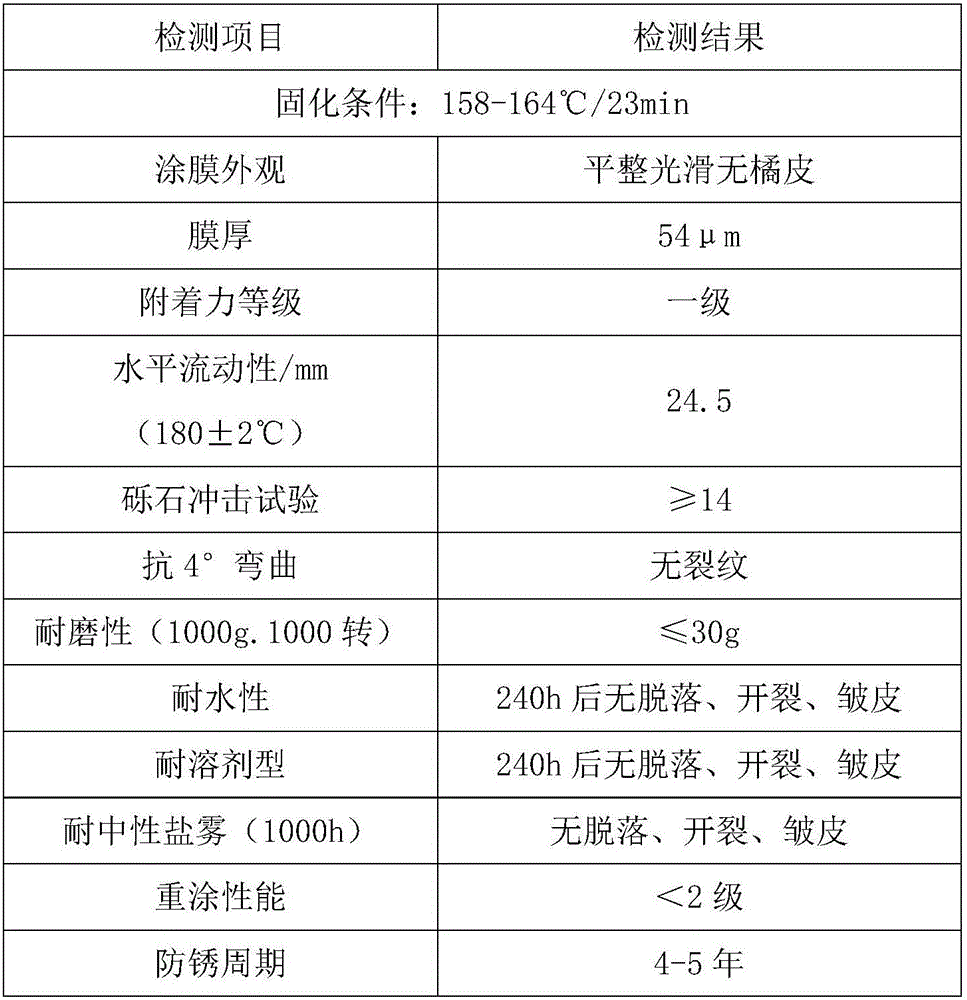

Image

Examples

Embodiment Construction

[0016] A composite nano-montmorillonite complex modified epoxy-based antirust powder coating for automobile chassis, the coating is made of the following raw materials in parts by weight: epoxy resin E-20 40, polyether modified epoxy Resin 20, organic fluorine epoxy resin 10, phenolic curing agent 30, nano-montmorillonite 3, phytic acid 1, polydiallyldimethylammonium chloride 0.4, aluminum tripolyphosphate / polymethyl methacrylate 10 microspheres, 0.5 benzoin, 0.5 antioxidant, 0.5 brightener, 20 deionized water, appropriate amount of dilute hydrochloric acid solution, and appropriate amount of 1% sodium hydroxide solution.

[0017] Wherein the aluminum tripolyphosphate / polymethyl methacrylate microspheres are made of the following raw materials in parts by weight: aluminum tripolyphosphate 4, methyl methacrylate 5, divinylbenzene 2, dibenzoyl peroxide 0.4, Deionized water 20, absolute ethanol 12, sodium lauryl sulfate 0.1, the preparation method is:

[0018] (1) First put sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com