A kind of cleaning agent for oil tanker and preparation method thereof

A cleaning agent and oil tanker technology, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problem of insufficient detergency and corrosion inhibition rate, low cleaning efficiency, and easy formation of rust film and other problems, to achieve the effect of improving corrosion and rust prevention, improving detergency, and high detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Sodium hydroxide 1.3%

[0022] Alkylbenzene sulfonic acid 18.7%

[0023] Sodium silicate 0.4%

[0024] Sodium carbonate 0.6%

[0025] Organic amine 1%

[0026] Coconut oil glycolamide 4%

[0027] Sorbitan oleate 1%

[0028] Fatty alcohol polyoxyethylene (3) ether 2%

[0029] Water margin.

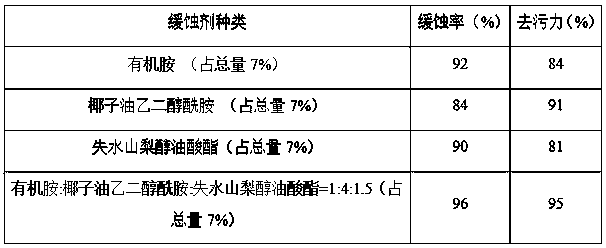

[0030] Compared with the corrosion inhibitor using organic amine (6% of the total) or coconut oil glycolamide (6% of the total) or sorbitan oleate (6% of the total), the results are as follows:

[0031]

[0032] Accurately measure sodium hydroxide and water, add to the blending kettle and stir to dissolve, then add alkylbenzene sulfonic acid and stir for about 60 minutes until the sodium alkylbenzene sulfonate solution is completely formed, and then add the measured sodium silicate, Sodium carbonate, organic amine, coconut oil glycol amide, sorbitan oleate and fatty alcohol polyoxyethylene (3) ether are stirred for 30 minutes, and then filtered to obtain an oil tank truck detergent.

Embodiment 2

[0034] Sodium hydroxide 2.1%

[0035] Alkylbenzene sulfonic acid 16.9%

[0036] Sodium silicate 0.5%

[0037] Sodium carbonate 0.5%

[0038] Organic amine 1%

[0039] Coconut oil glycolamide 4%

[0040] Sorbitan oleate 1.5%

[0041] Fatty alcohol polyoxyethylene (3) ether 2.5%

[0042] Water balance.

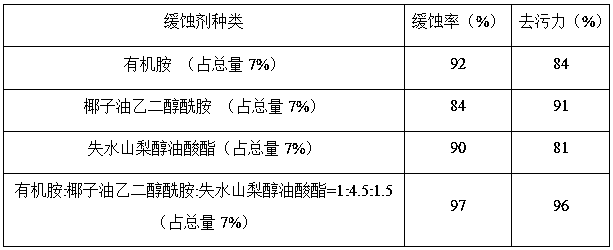

[0043] Compared with the corrosion inhibitor using organic amine (7% of the total) or coconut oil glycolamide (7% of the total) or sorbitan oleate (7% of the total), the results are as follows:

[0044]

[0045] Accurately measure sodium hydroxide and water, add to the blending kettle and stir to dissolve, then add alkylbenzene sulfonic acid and stir for about 60 minutes until the sodium alkylbenzene sulfonate solution is completely formed, and then add the measured sodium silicate, Sodium carbonate, organic amine, coconut oil glycol amide, sorbitan oleate and fatty alcohol polyoxyethylene (3) ether are stirred for 30 minutes, and then filtered to obtain an oil tank truck detergent.

Embodiment 3

[0047] Sodium hydroxide 2.2%

[0048] Alkylbenzene sulfonic acid 17.8%

[0049] Sodium silicate 0.6%

[0050] Sodium carbonate 0.4%

[0051] Organic amine 1%

[0052] Coconut oil glycolamide 4.5%

[0053] Sorbitan oleate 1.5%

[0054] Fatty alcohol polyoxyethylene (3) ether 2.5%

[0055] Water margin.

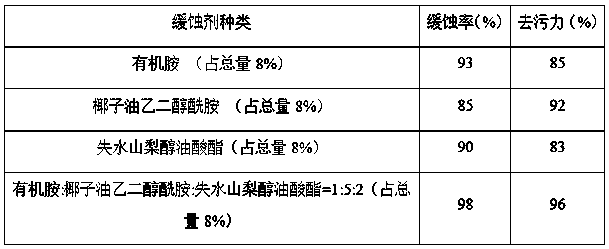

[0056] Compared with the corrosion inhibitor using organic amine (7% of the total) or coconut oil glycolamide (7% of the total) or sorbitan oleate (7% of the total), the results are as follows:

[0057]

[0058] Accurately measure sodium hydroxide and water, add them to the blending kettle and stir to dissolve, then add alkylbenzene sulfonic acid, stir for about 60 minutes, until the sodium alkylbenzene sulfonate solution is completely formed, and then add the measured sodium silicate, Sodium carbonate, organic amine, coconut oil glycol amide, sorbitan oleate and fatty alcohol polyoxyethylene (3) ether are stirred for 30 minutes, and then filtered to obtain an oil tank truck detergent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com