Thermoplastic starch and preparation method thereof

A technology of thermoplastic starch and corn starch, which is applied in the field of degradable polymer materials, can solve the problems of uneven distribution of components in the blend system, affecting the processing performance of thermoplastic starch, and affecting the dispersibility of starch, so as to reduce viscosity and achieve hydrophilicity properties, improve the plasticizing effect, improve the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

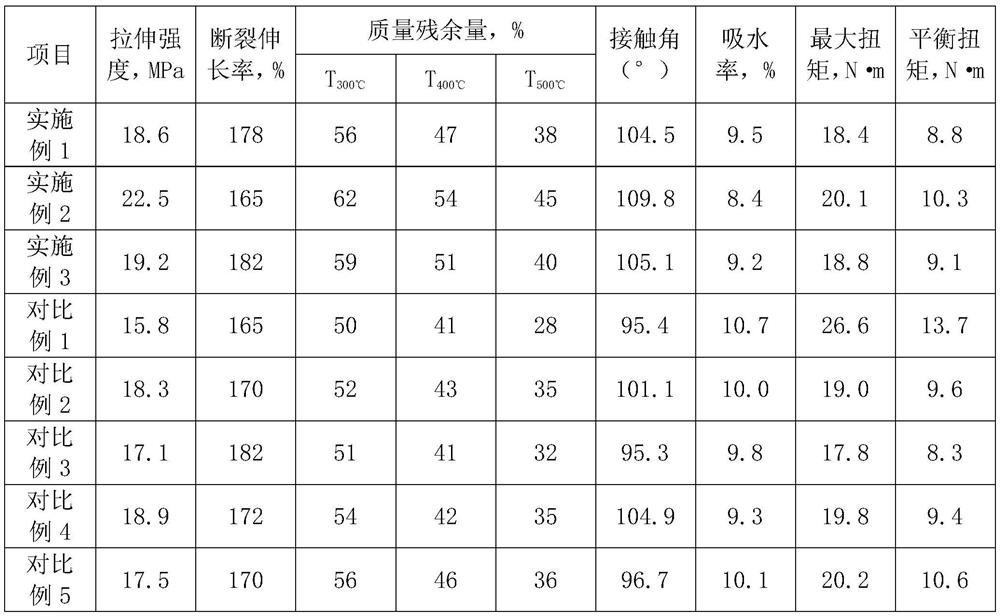

Examples

preparation example 1

[0040]Preparation example 1: ①Alkali gelatinization: Take 20kg of cassava residue with a fineness of 60 mesh and 100kg of water, heat to 80°C, then add 1kg of 5wt% sodium hydroxide solution, keep stirring at a speed of 200r / min for 10min, and then heat up To 90°C, keep stirring at a speed of 200r / min for 20min to obtain primary treated cassava residue;

[0041] ② Dispersion: After cooling down the primary treated cassava residue to 50°C, add 0.5 kg of sodium trimetaphosphate, and stir at a speed of 200 r / min for 3 minutes to obtain secondary processed cassava residue;

[0042] ③ Homogenization: Under the condition of 100Mpa, the secondary treated cassava residues were homogenized 3 times, each time for 20 minutes, to obtain three times processed cassava residues;

[0043] ④Modification: Add 3% of its weight of acetic anhydride and its weight of 1% of its weight of silane coupling agent KH550 to cassava residues treated three times, and stir and react at a speed of 1000r / min fo...

preparation example 2

[0045] Preparation example 2: 1. Alkali gelatinization: take 25kg of cassava residues with a fineness of 60 mesh and 100kg of water, heat to 85°C, then add 1.5kg of 6wt% sodium hydroxide solution, keep stirring at a speed of 200r / min for 15min, and then Raise the temperature to 95°C, keep stirring at a speed of 200r / min for 25min, and obtain primary processed cassava residue;

[0046] ②Dispersion: after cooling down the primary treated cassava residue to 52°C, add 0.75 kg of sodium trimetaphosphate, and stir at a speed of 200 r / min for 3 minutes to obtain secondary processed cassava residue;

[0047] ③ Homogenization: Under the condition of 110Mpa, the secondary treated cassava residues were homogenized 4 times, each time for 25 minutes, to obtain three times processed cassava residues;

[0048] ④Modification: add 4% acetic anhydride and 1.5% silane coupling agent KH550 to cassava residues treated three times, and stir at 1500r / min for 2-3 hours at a temperature of 75°C , to ...

preparation example 3

[0050] Preparation example 3: ①Alkali gelatinization: Take 30kg of cassava residue with a fineness of 60 mesh and 100kg of water, heat to 90°C, then add 2kg of 7wt% sodium hydroxide solution, keep stirring at a speed of 200r / min for 20min, and then heat up To 100°C, keep stirring at a speed of 200r / min for 30min to obtain primary treated cassava residue;

[0051] ② Dispersion: After cooling down the primary treated cassava residues to 55°C, add 1 kg of sodium trimetaphosphate, and stir for 3 minutes at a speed of 200 r / min to obtain secondary processed cassava residues;

[0052] ③ Homogenization: Under the condition of 120Mpa, the secondary treated cassava residues were homogenized 5 times, each time for 30 minutes, to obtain three times processed cassava residues;

[0053] ④Modification: Add 5% of its weight of acetic anhydride and its weight of 2% of its weight of silane coupling agent KH550 to cassava residues treated three times, and stir and react at a speed of 2000r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com