A CNC lathe for rough machining of planetary gears

A technology of CNC lathes and planetary gears, applied in the field of CNC lathes, can solve the problems of low work efficiency of staff, achieve the effects of saving manpower and time, simple structure, and ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

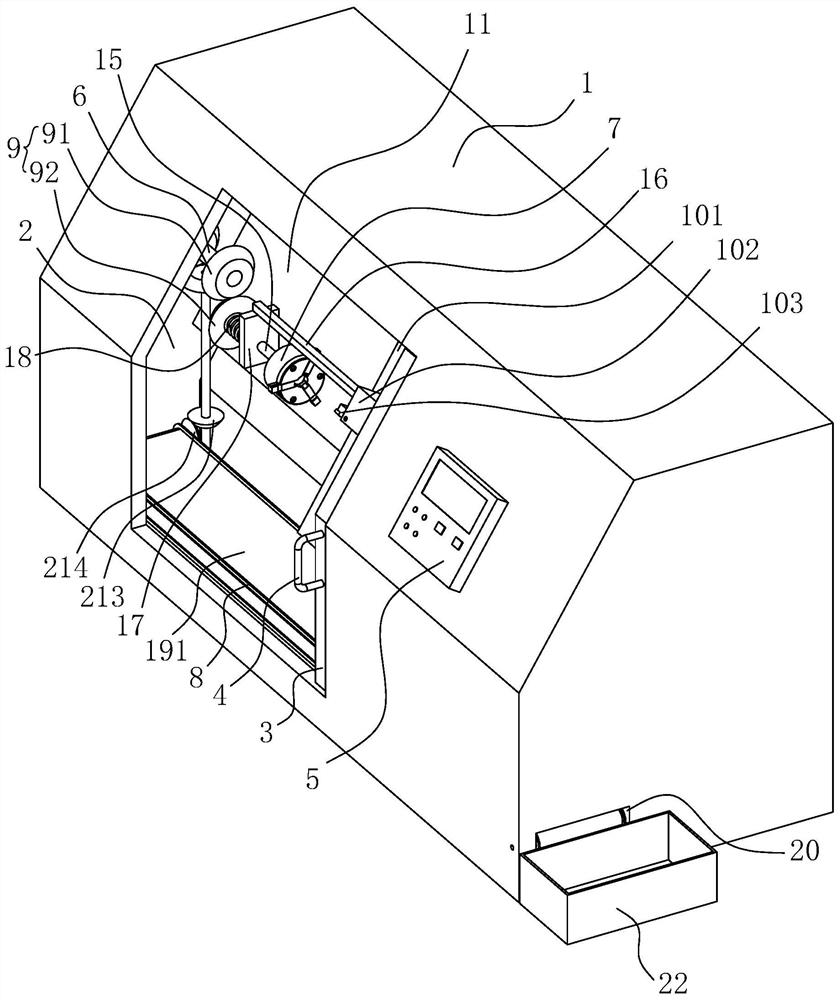

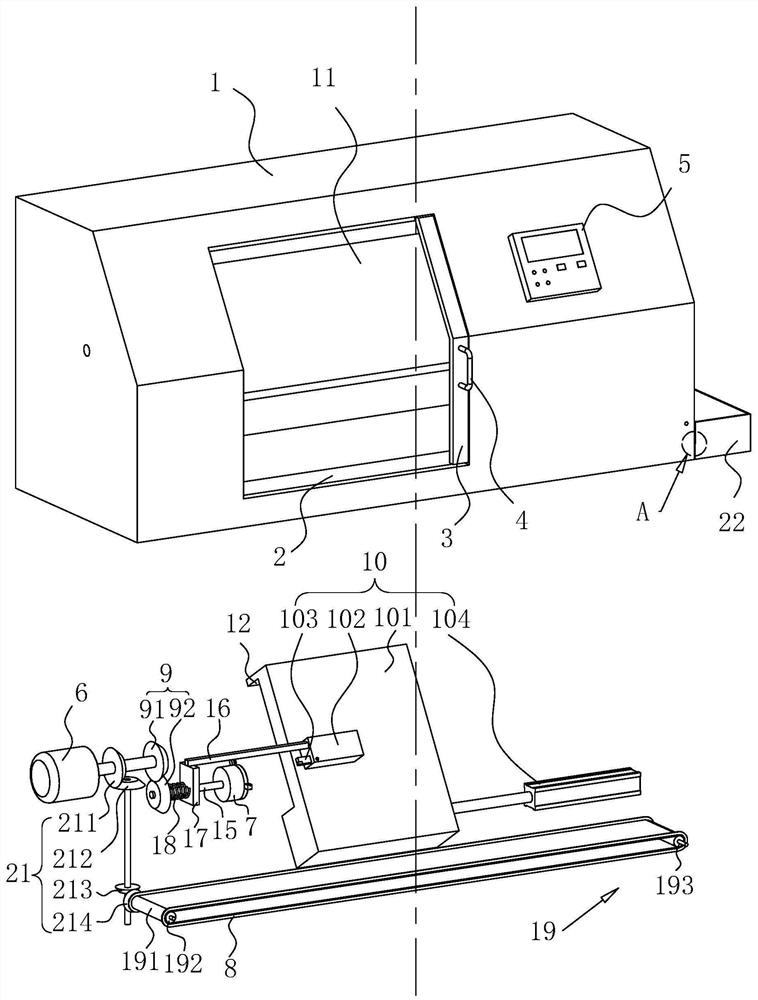

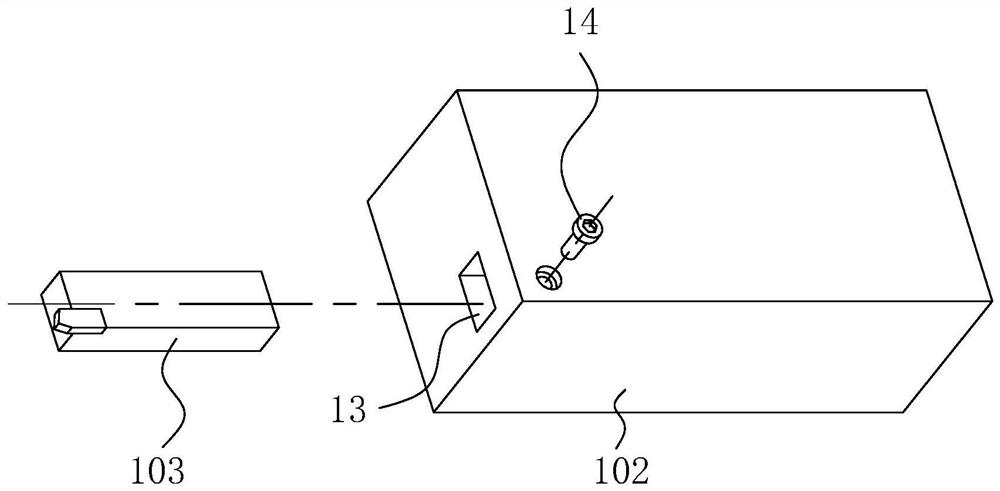

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses a numerically controlled lathe for rough machining of planetary gears. refer to figure 1 and figure 2 , the planetary gear rough machining CNC lathe includes a square body 1, a cavity-shaped working room 2 is provided in the body 1, and a rectangular parallelepiped protective door 3 is welded at the opening of the working room 2, and the protective door 3 is far away from the A U-shaped handle 4 is arranged on the side wall of the working chamber 2 . A cuboid operation panel 5 is arranged on the side wall where the protective door 3 outside the body 1 is located.

[0036] A rotary drive mechanism 6 is fixedly arranged on the outer wall of the body 1, and the output shaft of the rotary drive mechanism 6 penetrates the side wall of the body 1 and goes deep into the working chamber 2. The rotary drive mechanism 6 in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com