Treatment method of desulfurization solid waste

A treatment method, sulfur salt technology, applied in the field of desulfurization, can solve problems such as backlog, secondary pollution, and stacking space occupation, and achieve the effects of less tail gas, smooth materials, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

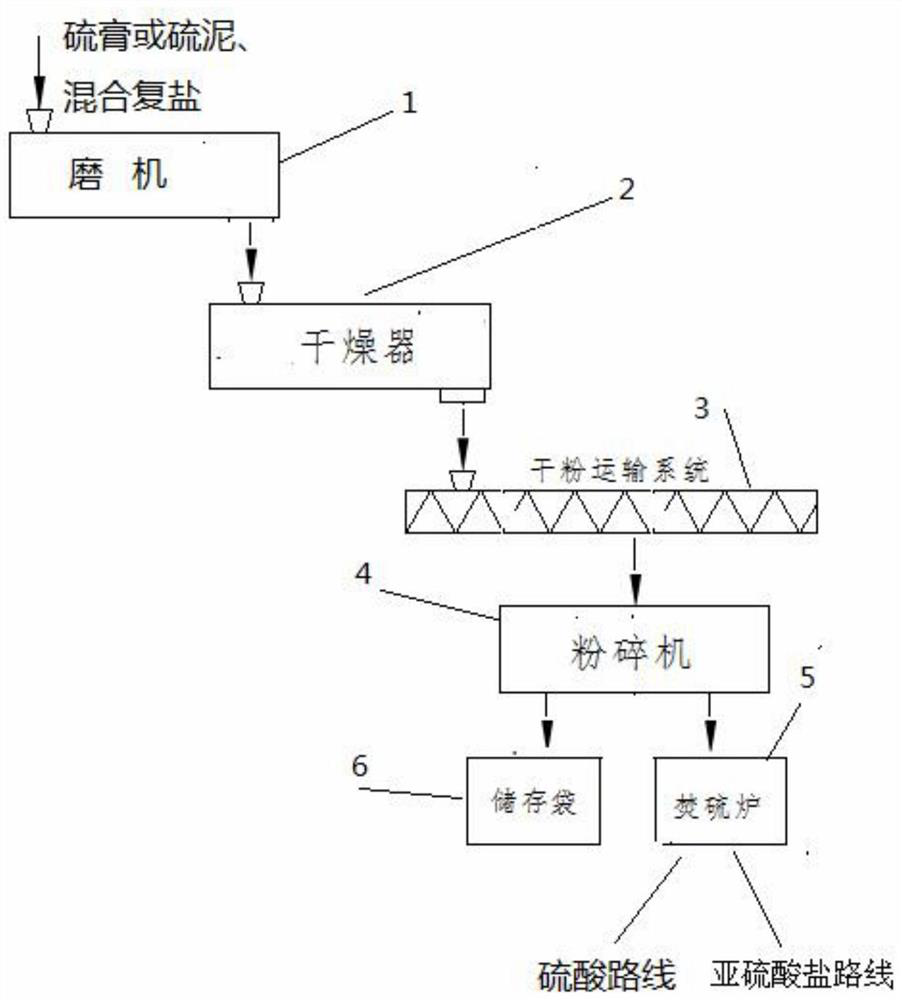

Method used

Image

Examples

Embodiment 1

[0026] In step a, the sulfur paste with a mass ratio of 1:1 and the mixed double salt are put into the mill 1 for mixing to obtain a porridge or pasty slurry sulfur salt mixture. Among them, the sulfur paste and the mixed double salt are directly selected from the sulfur paste and the mixed double salt of solid salt and sulfide produced by the coking enterprise through the desulfurization of the sulfur foam. Double salts are mixed.

[0027] In this embodiment, an automatic ball mill is selected to grind and mix the sulfur paste and the mixed double salt to ensure the mixing uniformity of the sulfur paste and the mixed double salt. Similarly, in other embodiments, according to the existing equipment conditions of the enterprise, also Mills with other structural forms can be selected for grinding and mixing sulfur paste and mixed double salts, such as colloid mills, stone wheel mills or other mechanical crushing machines.

Embodiment 2-4

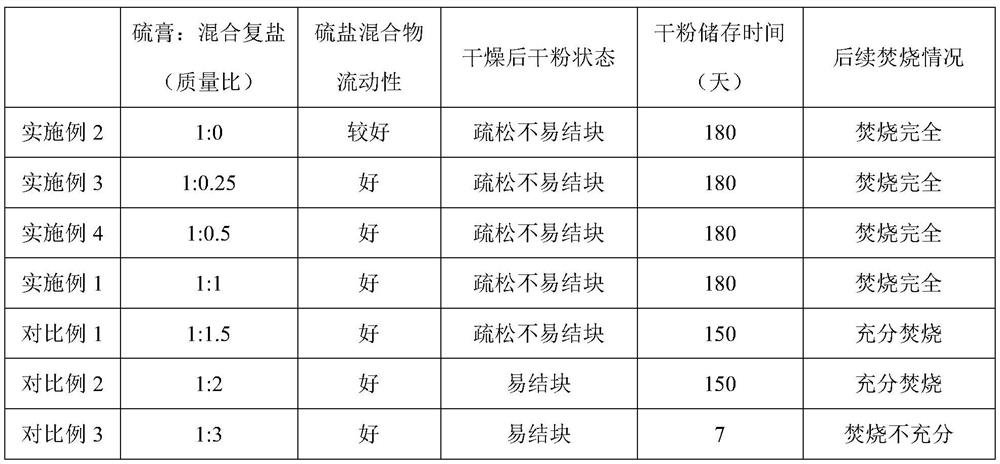

[0034] The processing method of embodiment 2-4 is identical with the method of embodiment 1, difference is that the mixing ratio of sulfur paste and mixed double salt is different, see table 1 for details.

Embodiment 5-7

[0041] The treatment method of Examples 5-7 is the same as that of Example 1, except that the amount of gram sulfur added is different, see Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com