A kind of wear-resistant and oxidation-resistant high-entropy alloy coating and preparation method thereof

A technology of alloy coating and oxidation high entropy, which is applied in the direction of metal material coating process and coating, can solve the problems of high preparation cost, easy cracks at the interface, high alloy content, etc., to ensure service life, guarantee engineering application, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

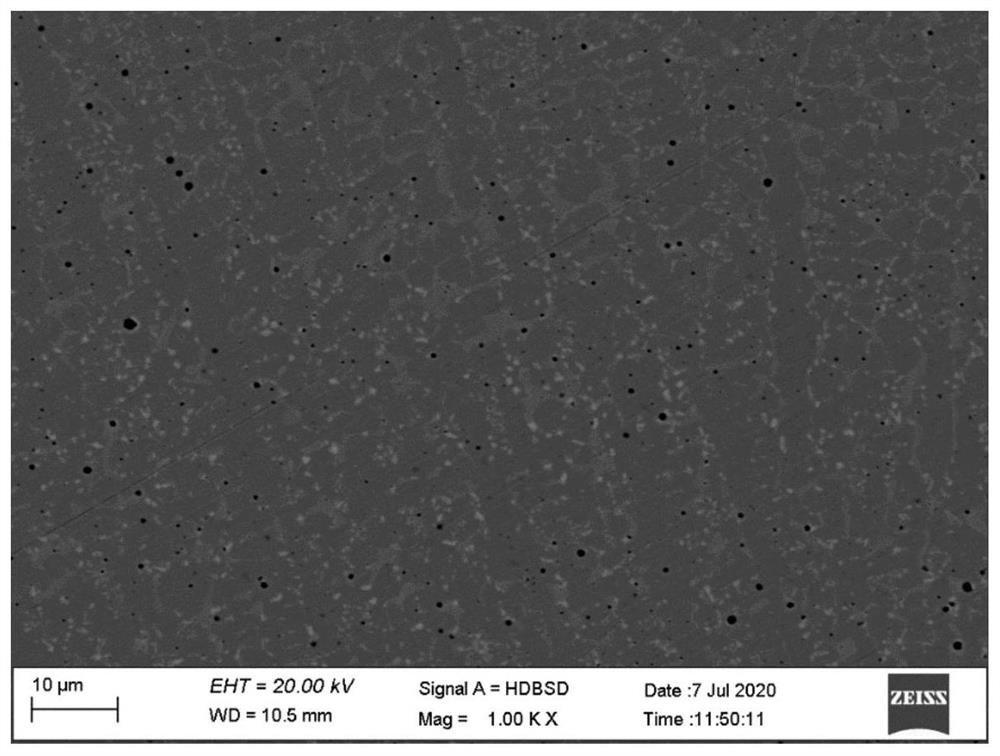

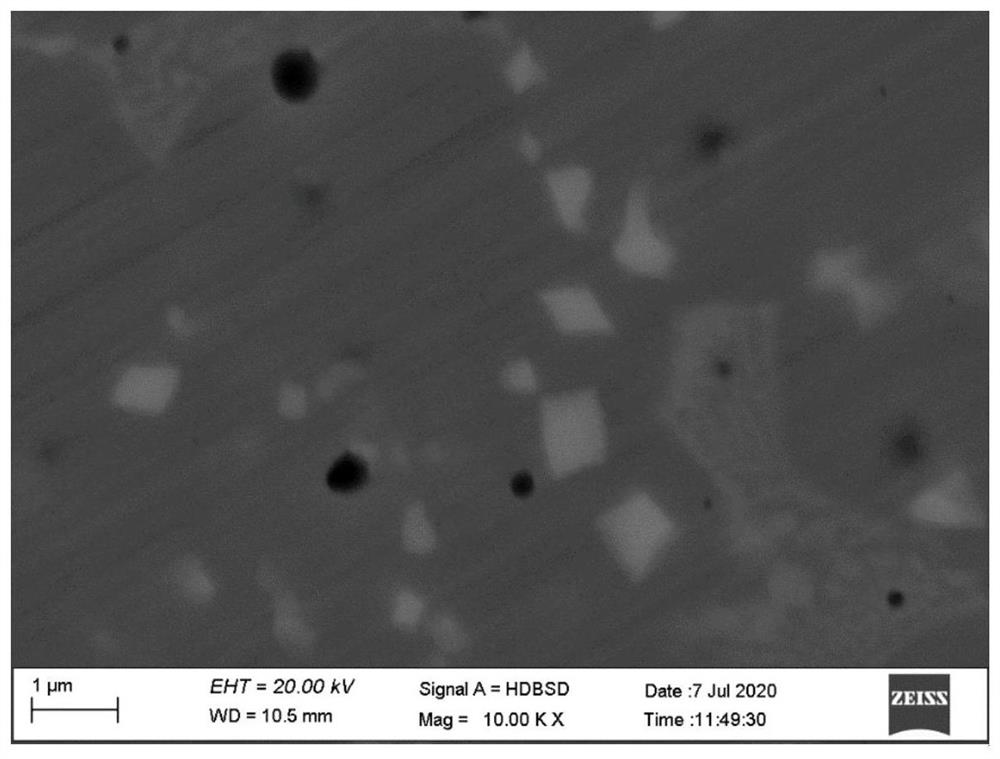

Embodiment 1

[0032] 13% Fe powder, 17% Co powder, 23% Cr powder, 18% Ni powder, 14% Nb powder, 4% FeSi75-A powder (containing Si 74-80%), 10% FeCr55C10 powder (containing Cr 60-65%, containing C10%, Fe balance) and 1% CeO 2 Put the powder into a ball mill with a size of 75 μm, a ball-to-material ratio of 5:1, and a rotation speed of 80 r / min, and mix uniformly for 10 hours. Mix the mixed powder with shellac alcohol solution to make a paste, and apply it on the surface of H13 steel. Using a multi-mode fiber laser, the beam diameter is 3mm, the laser power is 1200W, the scanning speed is 400mm / min, and the overlap rate 40%, cladding is carried out, and the hardness of the obtained coating is about 890HV. The coating was oxidized in air at 700°C for 100 hours, and the weight gain was only 0.07%.

Embodiment 2

[0034] The high-entropy alloy powder was prepared by atomization forming method, and the chemical quality of the coating composition was 17% Fe, 18% Co, 30% Cr, 17% Ni, 14% Nb, 3% Si and 1% c. Then add 1% CeO to the high entropy alloy powder 2 The powder is loaded into a dual-motion powder mixer at a speed of 30r / min, and mixed uniformly for 20 hours. Put the mixed powder into the powder feeding gas, the powder feeding gas is N 2 , using a multi-mode fiber laser, the powder feeding rate is 10g / min, the beam diameter is 3mm, the laser power is 2000W, the scanning speed is 300mm / min, the overlap rate is 40%, and the coating hardness is 920HV. about. The coating at 700°C N 2 , CO 2 with H 2 Oxygenated in a mixed gas for 100 hours, the weight gain is only 0.09%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com