High-thermal-conductivity flame-retardant polyolefin-based composite material and preparation method thereof

An olefin-based composite material and a composite material technology are applied in the field of high thermal conductivity flame-retardant polyolefin-based composite materials and their preparation, which can solve the problem of not significantly improving the interface interaction between filler and filler, filler and matrix, difficult to obtain comprehensive performance, The problem of poor compatibility between filler and matrix can achieve the effect of surface hydrophobic modification, strong force, and promotion of interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment relates to a method for preparing a high thermal conductivity and flame-retardant polyolefin-based composite material, which specifically includes the following steps:

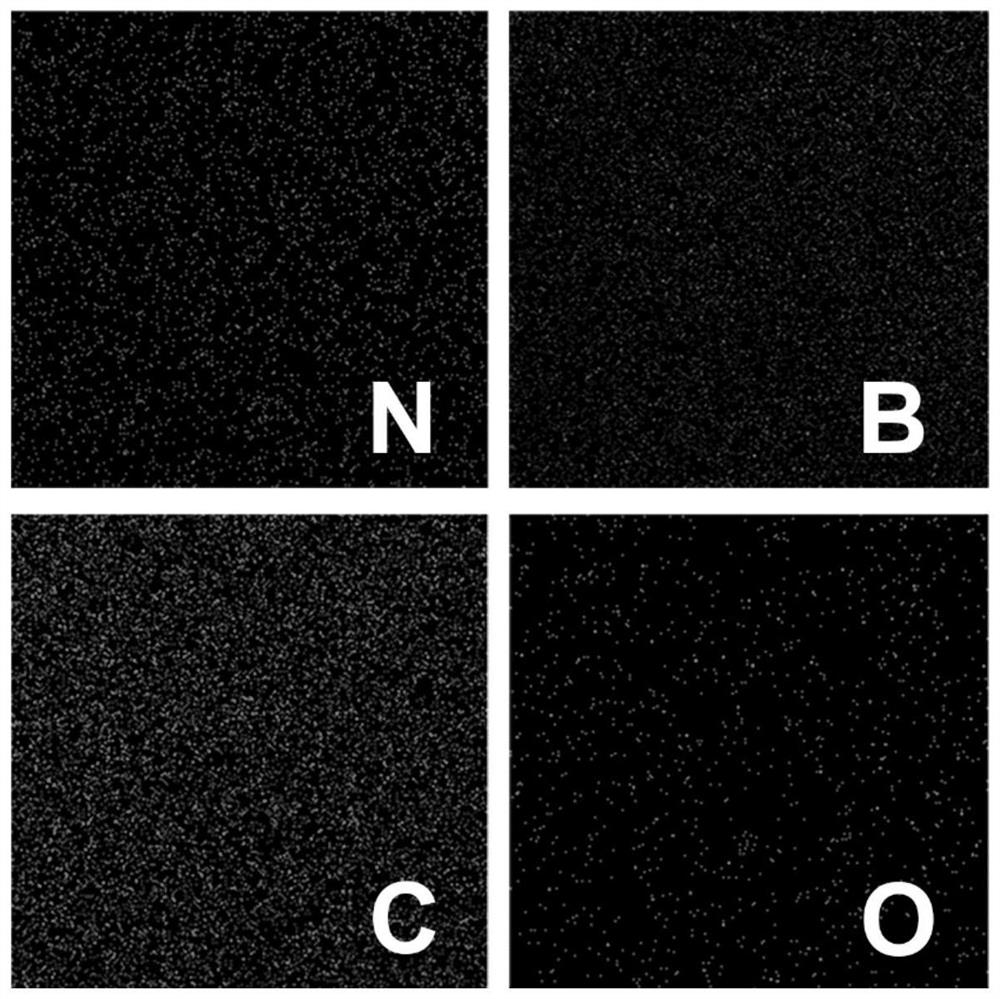

[0050] 1. Treat 100 parts by weight of boron nitride and 50 parts by weight of concentrated sulfuric acid through a hydrothermal method at 100°C for 5 hours, filter and wash to obtain a surface-functionalized boron nitride product, the reagent can be reused, and then in toluene solvent at 90°C Reflux treatment with 10 parts by weight of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate for 0.5 h to obtain pretreated boron nitride.

[0051] 2. Pretreated boron nitride with a concentration of 5 mg / ml and 0.1 parts by weight of graphene oxide with a concentration of 5 mg / ml are stirred to obtain an aqueous dispersion of self-assembled boron nitride coated with graphene oxide , the intermediate.

[0052] 3. Mix the prepared intermediate with 0.05 parts by weight of dodecyl...

Embodiment 2

[0056] This embodiment relates to a method for preparing a high thermal conductivity and flame-retardant polyolefin-based composite material, which specifically includes the following steps:

[0057] 1. Treat 100 parts by weight of boron nitride and 200 parts by weight of concentrated hydrochloric acid by hydrothermal method at 120°C for 5 hours, filter and wash to obtain surface-functionalized boron nitride, the reagent can be reused, and then mix it with toluene solvent at 90°C 10 parts by weight of isopropyl triisostearate titanate were refluxed for 2 hours to obtain pretreated boron nitride.

[0058] 2. The pretreated boron nitride aqueous dispersion with a concentration of 10 mg / ml and 2 parts by weight of a graphene oxide aqueous dispersion with a concentration of 2 mg / ml are stirred to obtain self-assembled nitrogen coated with graphene oxide. The aqueous dispersion of boron chloride, that is, the intermediate.

[0059] 3. Mix the prepared intermediate with 4 parts by ...

Embodiment 3

[0063] This embodiment relates to a method for preparing a high thermal conductivity and flame-retardant polyolefin-based composite material, which specifically includes the following steps:

[0064] 1. Treat 100 parts by weight of boron nitride and 100 parts by weight of concentrated nitric acid by hydrothermal method at 150 ° C for 10 h, filter and wash to obtain surface functionalized boron nitride, the reagent can be reused, and then mix it with toluene solvent at 100 ° C 5 parts by weight of γ-glycidyl etheroxypropyltrimethoxysilane were refluxed for 5 hours to obtain pretreated boron nitride.

[0065] 2. The pretreated boron nitride aqueous dispersion with a concentration of 20 mg / ml and 5 parts by weight of a graphene oxide aqueous dispersion with a concentration of 6 mg / ml are stirred to obtain self-assembled nitrogen coated with graphene oxide. The aqueous dispersion of boron chloride, that is, the intermediate.

[0066] 3. Mix the prepared intermediate with 3 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com