A kind of structure and preparation method of prebaked continuous independently reinforced carbon bowl anode carbon block

A technology of anode carbon block and carbon bowl is applied in the field of pre-baking continuous and independent strengthening of carbon bowl anode carbon block structure and preparation, which can solve the problems of reducing electrolysis efficiency, electrolyte power failure, heat waste, etc., so as to reduce environmental pollution and ensure stability. Work, avoid the effect of aluminum water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

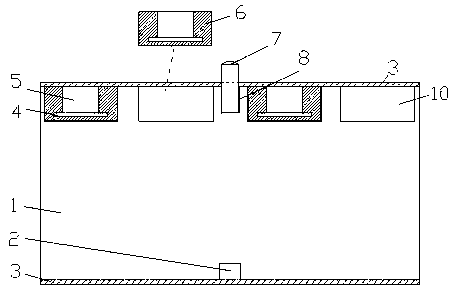

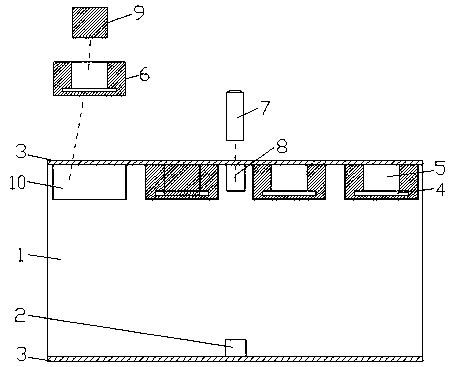

[0040] Example 1. A prebaked continuous independent reinforced carbon bowl anode carbon block structure and preparation method, the composition is as follows Figure 1-2 As shown, there is a carbon block body 1, the upper end of the carbon block body 1 is provided with a carbon bowl assembly connection pit 10, and the carbon bowl assembly connection pit 10 is provided with a reinforced carbon bowl assembly 6, and the reinforced carbon bowl assembly 6 A charcoal bowl 5 is arranged on the top, and the reinforced charcoal bowl assembly 6 at the bottom of the charcoal bowl 5 is provided with a mechanical steel claw connection ring groove 4.

[0041] The carbon bowl 5 on the reinforced charcoal bowl assembly 6 is provided with a prefabricated split charcoal bowl filling block 9 .

[0042] The middle of the upper part of the carbon block body 1 is provided with a connecting protrusion 7 through the bonding groove 8 of the connecting protrusion, and the middle of the bottom of the c...

Embodiment 2

[0052] Example 2. A prebaked continuous independent reinforced carbon bowl anode carbon block structure and preparation method, the composition is as follows Figure 1-2 As shown, there is a carbon block body 1, the upper end of the carbon block body 1 is provided with a carbon bowl assembly connection pit 10, and the carbon bowl assembly connection pit 10 is provided with a reinforced carbon bowl assembly 6, and the reinforced carbon bowl assembly 6 A charcoal bowl 5 is arranged on the top, and the reinforced charcoal bowl assembly 6 at the bottom of the charcoal bowl 5 is provided with a mechanical steel claw connection ring groove 4.

[0053] The carbon bowl 5 on the reinforced charcoal bowl assembly 6 is provided with a prefabricated split charcoal bowl filling block 9 .

[0054] The middle of the upper part of the carbon block body 1 is provided with a connecting protrusion 7 through the bonding groove 8 of the connecting protrusion, and the middle of the bottom of the c...

Embodiment 3

[0062] Example 3. A prebaked continuous independent reinforced carbon bowl anode carbon block structure and preparation method, the composition is as follows Figure 1-2As shown, there is a carbon block body 1, the upper end of the carbon block body 1 is provided with a carbon bowl assembly connection pit 10, and the carbon bowl assembly connection pit 10 is provided with a reinforced carbon bowl assembly 6, and the reinforced carbon bowl assembly 6 A charcoal bowl 5 is arranged on the top, and the reinforced charcoal bowl assembly 6 at the bottom of the charcoal bowl 5 is provided with a mechanical steel claw connection ring groove 4.

[0063] The carbon bowl 5 on the reinforced charcoal bowl assembly 6 is provided with a prefabricated split charcoal bowl filling block 9 .

[0064] The middle of the upper part of the carbon block body 1 is provided with a connecting protrusion 7 through the bonding groove 8 of the connecting protrusion, and the middle of the bottom of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com