Fresh-keeping storage method for grape grains

A grape and antistaling agent technology, which is applied in the fields of fruit and vegetable preservation, botanical equipment and methods, food preservation, etc., can solve problems such as endangering human health, threshing, environmental and food pollution, and achieve advanced and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

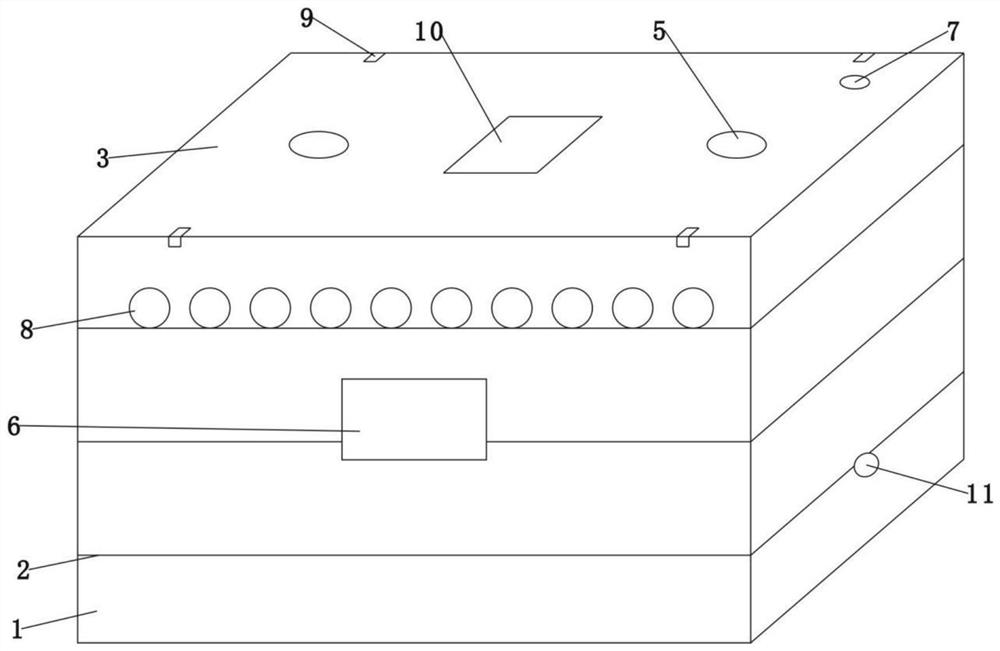

Method used

Image

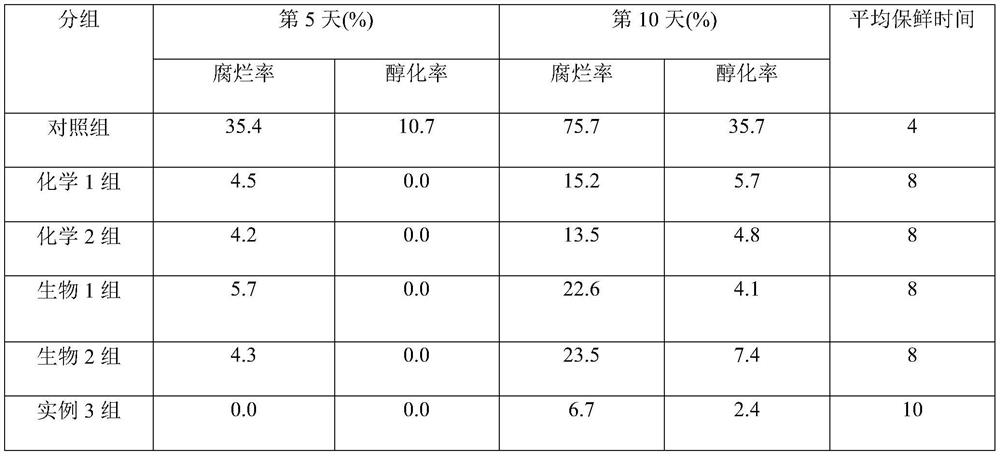

Examples

Embodiment 1

[0045] A method for fresh-keeping and storing grape grains, comprising:

[0046] (1) Spray fresh-keeping and water-retaining agent 3 days before harvesting, fresh-keeping agent is made by mixing chitosan 5%, 1-methylcyclopropene 50% (emulsifier), enzyme inhibitor 5%, and surplus deionized water become;

[0047] (2) Pre-cooling and water-retaining agent: Put the whole bunch of grapes into a water-retaining agent at 5°C and pre-cool for 1 minute. , 3% stearic acid, 5% soybean oil, and the rest of deionized water. First put the deionized water into the reactor, heat and melt the filler at 110°C and stir evenly. The stirring speed is 200r / min, and the stirring and emulsifying time is about After 30 minutes, a W / O emulsion is formed, and finally the temperature is rapidly cooled to 40°C;

[0048](3) Cutting and grading fresh-keeping treatment: the pre-cooled whole bunch of grapes, drained, then cut and grading, leaving the short fruit stalk above the fruit, removing the fruit wit...

Embodiment 2

[0053] A method for fresh-keeping and storing grape grains, comprising:

[0054] (1) Spraying fresh-keeping and water-retaining agent 3 days before harvesting, fresh-keeping agent is made by mixing chitosan 7%, 1-methylcyclopropene 50% (emulsifier), enzyme inhibitor 5%, deionized water;

[0055] (2) Pre-cooling and water-retaining agent: Put the whole bunch of grapes into a water-retaining agent at 5°C and pre-cool for 2 minutes. %, 6% stearic acid, 8% soybean oil, and the rest deionized water. First put the deionized water into the reactor, heat and melt the filler at 115°C and stir evenly. The stirring speed is 300r / min, and the emulsification time is For about 35 minutes, a W / O emulsion is formed, and finally cooled rapidly to 42°C;

[0056] (3) Cutting and grading fresh-keeping treatment: the pre-cooled whole bunch of grapes, drained, then cut and grading, leaving the short fruit stalk above the fruit, removing the fruit with rotten diseases and insect pests, and putting ...

Embodiment 3

[0061] A method for fresh-keeping and storing grape grains, comprising:

[0062] (1) Spraying fresh-keeping and water-retaining agent 3 days before harvesting, fresh-keeping agent is made by mixing chitosan 10%, 1-methylcyclopropene 55% (emulsifier), enzyme inhibitor 10%, and deionized water;

[0063] (2) Pre-cooling and water-retaining agent: put the whole bunch of grapes into a water-retaining agent at 5°C, and pre-cool for 3 minutes. %, 8% stearic acid, 10% soybean oil, and the rest deionized water. First put the deionized water into the reactor, heat and melt the filler at 120°C and stir evenly. The stirring speed is 400r / min, and the emulsification time is For about 40 minutes, a W / O emulsion is formed, and finally cooled rapidly to below 45°C;

[0064] (3) Cutting and grading fresh-keeping treatment: the pre-cooled whole bunch of grapes, drained, then cut and grading, leaving the short fruit stalk above the fruit, removing the fruit with rotten diseases and insect pests...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com