Halogenated solid electrolyte material, flexible solid electrolyte membrane, lithium battery and preparation methods thereof

A solid electrolyte membrane and solid electrolyte technology, applied in the field of lithium ion batteries, can solve the problems of large thickness of solid electrolyte layer, unstable lithium metal, lack of flexibility, etc., and achieve good chemical/electrochemical stability, stable crystal structure, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The second aspect of the present invention provides a method for preparing a halogenated solid electrolyte material, comprising the following steps:

[0049] S1. Mixing and reacting the weighed raw materials to obtain a preliminary crystallization mixture;

[0050] S2. Under an inert atmosphere and / or a vacuum atmosphere, heat-treat and cool the primary crystallized mixture to obtain the halogenated solid electrolyte material;

[0051] Wherein, the raw material is at least one of halides, sulfates and silicates containing lithium, halides, sulfates and silicates containing M, and halides, sulfates and silicates containing M'; M is selected from group IIIB elements and / or group IIIA elements, and M' is selected from at least one of group IIA elements, group IB elements, group IIB elements, group IVB elements, group VIII elements and group VIII elements;

[0052] The consumption of described raw material makes the obtained halogenated solid electrolyte material have the ...

Embodiment 1

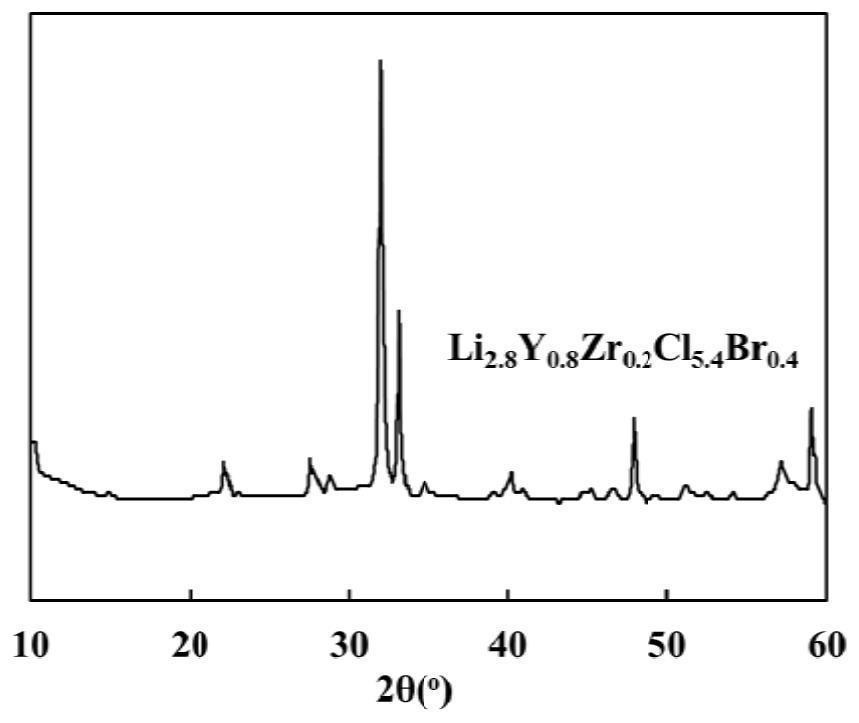

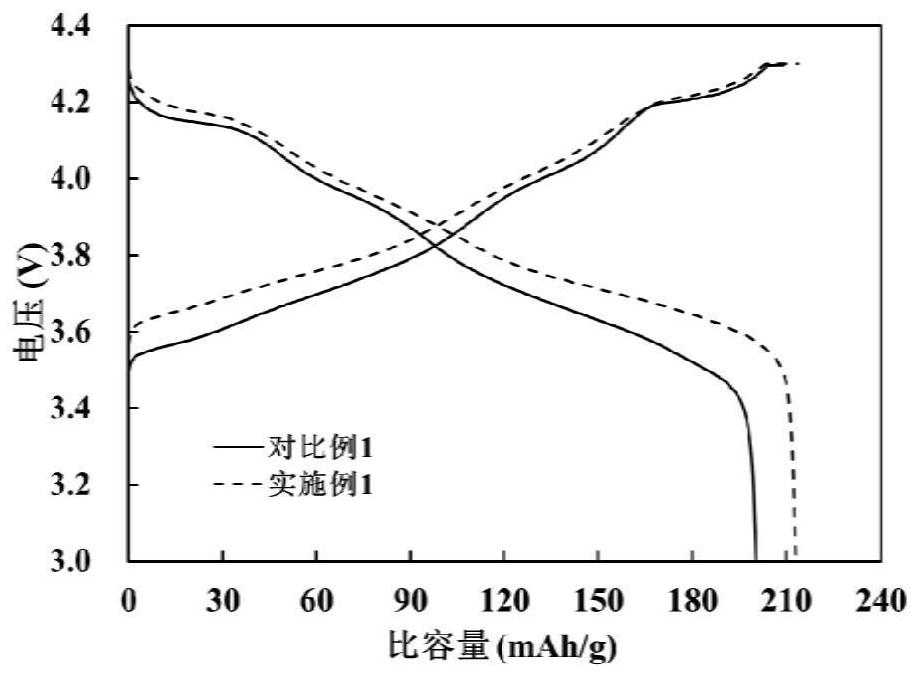

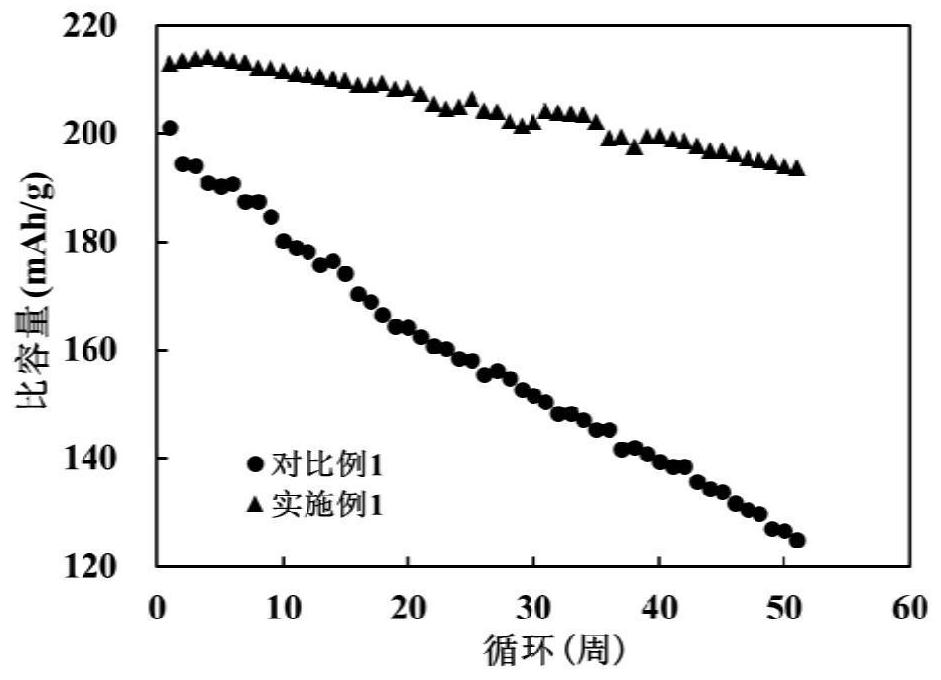

[0101] Step 1. Li 2.8 Y 0.8 Zr 0.2 Cl 5.4 Br 0.4 Preparation: Weigh YCl according to the stoichiometric ratio 3 , ZrCl 4 , LiBr and LiCl raw materials are placed in a ball mill tank, and ball milled with zirconia balls. The ratio of small balls to large balls is 1:1, the ratio of balls to materials is 2:1, and the rotation speed is 550rpm. After separation, it was placed in a corundum porcelain boat, calcined at 460°C for 12 hours in a tube furnace with a nitrogen atmosphere, and cooled with the furnace to obtain Li 2.8 Y 0.8 Zr 0.2 Cl 5.4 Br 0.4 .

[0102] Step 2, preparation of flexible halide electrolyte membrane: the Li obtained in step 1 2.8 Y 0.8 Zr 0.2 Cl 5.4 Br 0.4 , LiTFSI and PEO were uniformly mixed in a stirrer at a mass ratio of 8:1:1, and then the above mixture was laminated on a polyester film using a hot press to obtain a halide electrolyte membrane containing a substrate.

[0103] Step 3, preparation of membrane electrode: positive electrode ma...

Embodiment 2

[0108] Step 1. Li 3 InCl 3 Br 3 Preparation: Weigh InCl according to the stoichiometric ratio 3 , LiBr and LiCl raw materials are placed in a ball mill tank, and ball milled with zirconia balls, the ratio of small balls to large balls is 1:1, the ratio of balls to materials is 2:1, the speed is 500rpm, and the samples are taken out after ball milling for 6 hours, and the balls are sieved After separation, it was placed in a corundum porcelain boat, calcined at 580°C for 4 hours in a tube furnace with a nitrogen atmosphere, and cooled with the furnace to obtain Li 3 InCl 3 Br 3 .

[0109] Step 2, preparation of flexible halide electrolyte membrane: the Li obtained in step 1 3 InCl 3 Br 3 , LiTFSI, PMMA and PEO were uniformly mixed in a mixer at a mass ratio of 50:28:10:12, and then the above mixture was laminated on a polyester film using a hot press to obtain a halide electrolyte membrane containing a substrate.

[0110] Step 3, preparation of membrane electrode: posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com