Carbon nanotube foam material with electromagnetic shielding performance, and preparation method and application thereof

A technology of carbon nanotubes and foam materials, applied in the fields of magnetic/electric field shielding, metal material coating technology, electrical components, etc., can solve the problem of reduced mechanical properties of shielding materials, inability to meet the requirements of light weight, and inability to have both mechanical properties, etc. problems, to achieve the effect of expanding mass production, controllable density and thickness, and excellent shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

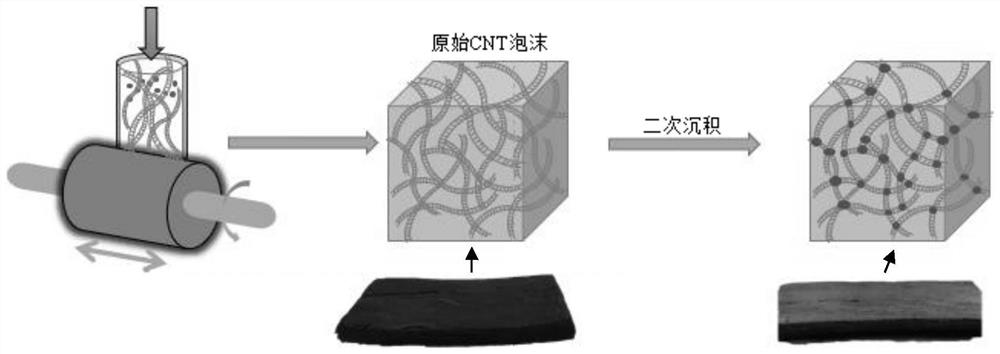

[0032] The preparation principle of the present invention is: the present invention utilizes the carbon nanotube foam grown by the floating CVD method, uses ethylene, etc. as the carbon source, and passes through the carrier and the carbon source to perform secondary deposition of amorphous carbon on the original carbon nanotube foam. After secondary deposition, the carbon nanotube foam changed from the original collapsible network structure to a self-supporting 3D network structure. Due to the excellent electrical conductivity of carbon nanotubes, the foam has a high reflection of electromagnetic waves, and the remaining electromagnetic waves enter the interior of the foam. absorption efficiency.

[0033] One aspect of the embodiments of the present invention provides a method for preparing a carbon nanotube foam material with electromagnetic shielding properties, comprising:

[0034] Provide carbon nanotube foam;

[0035] placing the carbon nanotube foam in a reaction cham...

Embodiment 1

[0057] Example 1 as figure 1 As shown, a preparation method of a carbon nanotube foam material with electromagnetic shielding properties comprises the following specific technical steps:

[0058] 1) Raw carbon nanotube foam: the carbon nanotube fibers produced by floating CVD are collected and wound on a collecting shaft.

[0059] 2) Sample preparation: Cut the pristine carbon nanotube foam into regular rectangles with a laser.

[0060] 3) Preparing original carbon nanotube foams with different thicknesses: Prepare spacers with standard sizes (1mm, 2mm, 3mm, 5mm, 10mm), and press the original carbon nanotube foams into different thicknesses respectively.

[0061] 4) Secondary deposition: Put the foam in 3) into the quartz boat, push the quartz boat into the middle of the quartz tube, install the flanges at both ends of the quartz tube, and then pass argon gas to remove the air in the quartz tube. The flow rate of argon gas is 200-250 sccm, the temperature is raised to 1000-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com