Odor-removing anticorrosive finishing paint coating and preparation method thereof

A technology for deodorization and coatings, applied in the field of coatings, can solve the problems of decreased ability to induce negative ions, decreased pyroelectric and piezoelectric properties of anion materials, low deodorization and formaldehyde removal capabilities, etc., to achieve good deodorization and The ability to remove formaldehyde, improve the photocatalytic effect, and the effect of strong negative ion induction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

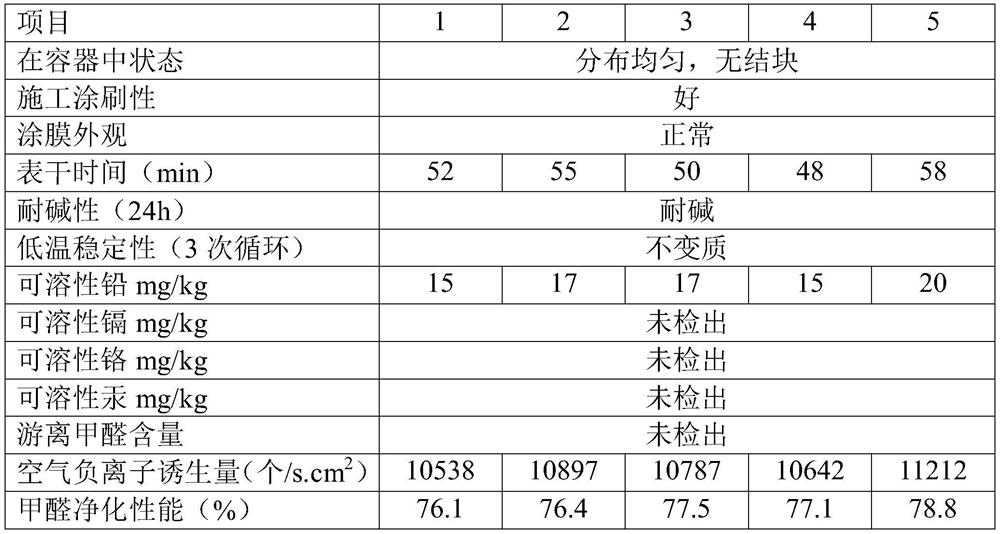

Examples

preparation example Construction

[0026] A method for preparing a clean-odour anti-corrosion finish paint, weighing each component by parts by weight; The agent is uniformly dispersed in water under the condition of medium-speed stirring, and then add R706 titanium dioxide, kaolin, talcum powder, heavy calcium carbonate, and loaded TiO 2 Composite photocatalytic material, modified negative ion powder, high-speed stirring for 50-80 minutes, then grinding and dispersing to make the slurry fineness below 40 μm, then adding deodorizing emulsion and stirring at high speed for 40-60 minutes, mixing evenly, adjusting the viscosity, and obtaining the coating. Obtain clean odor anti-corrosion finish paint.

[0027] The stirring speed of medium-speed stirring is 400-550r / min, and the stirring speed of high-speed stirring is 1550-1700r / min.

Embodiment 1

[0028] Embodiment 1, a kind of anti-corrosion finish paint of net odor, comprises components by mass parts: 30 parts of water, 0.8 part of dispersant, 0.3 part of defoamer, 0.2 part of wetting agent, 0.2 part of preservative, anti-mildew 0.5 parts of agent, 1 part of deodorizing film-forming aid, 1.8 parts of environmental protection antifreeze, 20 parts of R706 titanium dioxide, 4 parts of kaolin, 3 parts of talcum powder, 8 parts of heavy calcium carbonate, 27 parts of deodorant emulsion, and TiO 2 2 parts of composite photocatalytic material, 3 parts of modified anion powder.

[0029] Attached TiO 2 Composite photocatalytic materials including natural diatomaceous earth support and nano-TiO 2 Catalytic active component, nano TiO 2 The loading amount of the catalytically active component is 30%.

[0030] Attached TiO 2 Composite photocatalytic material preparation, mix natural diatom concentrate and water at a ratio of 1:15, and slowly add concentrated hydrochloric acid ...

Embodiment 2

[0036] Embodiment 2, a kind of clean antiseptic finish paint, comprises components by mass parts: 32 parts of water, 0.9 part of dispersant, 0.4 part of defoamer, 0.3 part of wetting agent, 0.4 part of preservative, anti-mildew 0.6 parts of agent, 2 parts of deodorizing film-forming aid, 2 parts of environmental protection antifreeze, 22 parts of R706 titanium dioxide, 6 parts of kaolin, 4 parts of talcum powder, 12 parts of heavy calcium carbonate, 35 parts of deodorizing emulsion, and TiO 2 2.5 parts of composite photocatalytic material, 4 parts of modified anion powder.

[0037] Attached TiO 2 Composite photocatalytic materials including natural diatomaceous earth support and nano-TiO 2 Catalytic active component, nano TiO 2 The loading amount of the catalytically active component is 35%.

[0038] Attached TiO 2 Composite photocatalytic material preparation, mix natural diatom concentrate and water at a ratio of 1:15, and slowly add concentrated hydrochloric acid and 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com