Preparation method of lithium ion battery positive electrode material NCM811

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of increasing Li+ diffusion kinetic resistance, poor high temperature performance, restricting commercialization, etc., and achieves suppression of cation mixing. , the effect of reducing the possibility and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

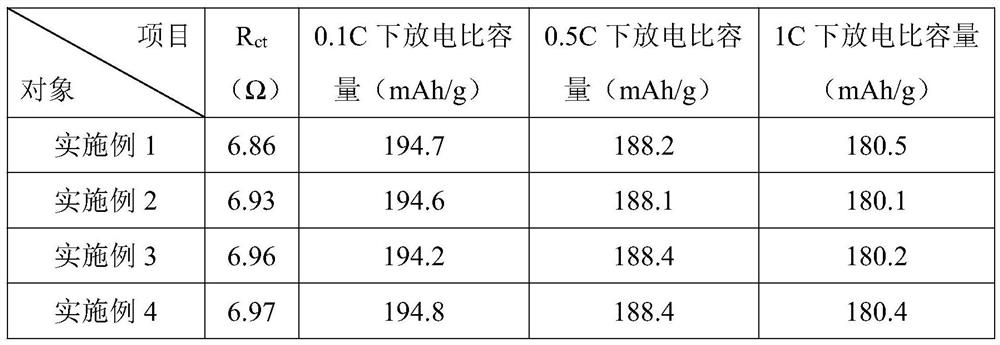

[0022] A preparation method of lithium-ion battery cathode material NCM811, specifically comprising the steps of:

[0023] S1: Add nickel sulfate, cobalt sulfate and manganese sulfate into deionized water according to the molar ratio n(Ni):n(Co):n(Mn)=0.8:0.1:0.1, stir ultrasonically to dissolve them fully, and then add the concentration It is 8.2mol / L ammonia solution, adjust the pH value to 11.3, heat to 65°C, stir for 15h, filter, and dry the filter residue at 80°C to obtain the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 .

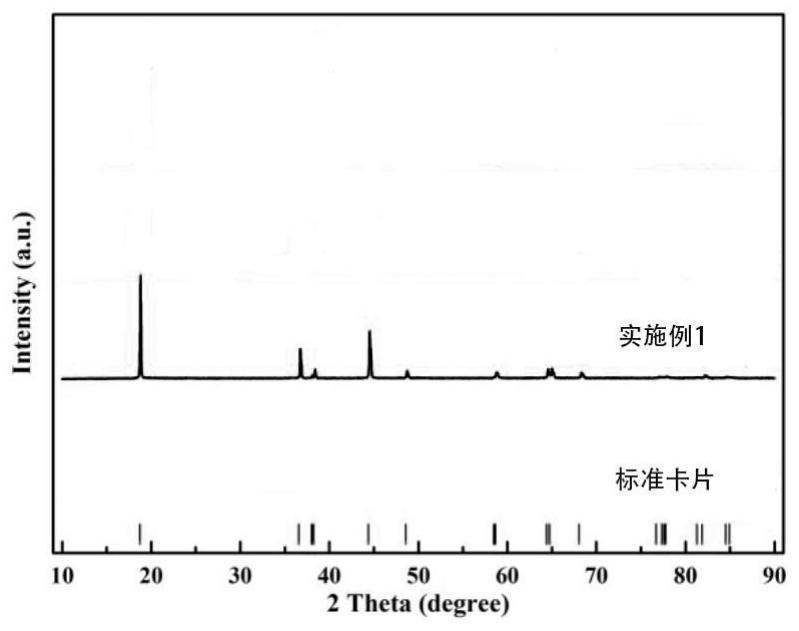

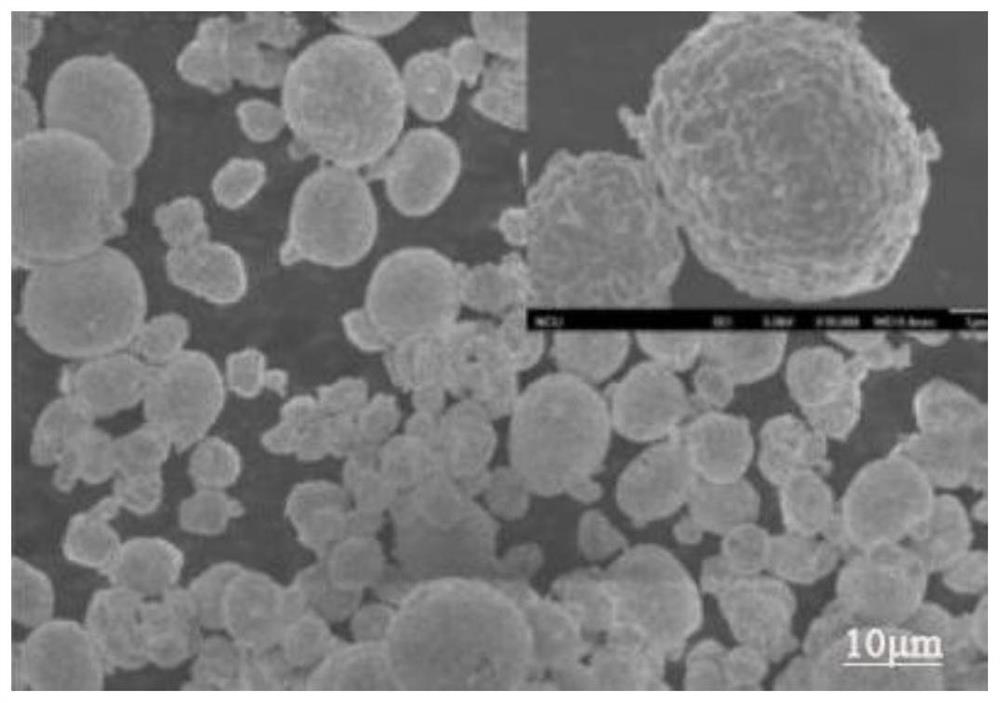

[0024] S2: the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 and lithium hydroxide were added to the mortar, and the grinding was continued for 30min, in which the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio of lithium hydroxide to lithium hydroxide is 1:1.06, and then placed in a tube furnace, the air is first evacuated with nitrogen, and then oxygen is introduced at a flow rate of 0.18L / min, and the temperature is raised to 350°C and then kept ...

Embodiment 2

[0027] A preparation method of lithium-ion battery cathode material NCM811, specifically comprising the steps of:

[0028] S1: Add nickel sulfate, cobalt sulfate and manganese sulfate into deionized water according to the molar ratio n(Ni):n(Co):n(Mn)=0.8:0.1:0.1, stir ultrasonically to dissolve them fully, and then add the concentration It is 8.5mol / L ammonia solution, adjust the pH value to 11.6, heat to 85°C, stir for 24h, filter, and dry the filter residue at 90°C to obtain the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 .

[0029] S2: the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 and lithium hydroxide were added to the mortar, and the grinding was continued for 50min, in which the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio of lithium hydroxide to lithium hydroxide is 1:1.21, and then placed in a tube furnace, the air is first evacuated with nitrogen, and then oxygen is introduced at a flow rate of 0.21L / min, and the temperature is raised to 380°C and then kept ...

Embodiment 3

[0032] A preparation method of lithium-ion battery cathode material NCM811, specifically comprising the steps of:

[0033] S1: Add nickel sulfate, cobalt sulfate and manganese sulfate into deionized water according to the molar ratio n(Ni):n(Co):n(Mn)=0.8:0.1:0.1, stir ultrasonically to dissolve them fully, and then add the concentration It is 8.3mol / L ammonia solution, adjust the pH value to 11.4, heat to 70°C, stir and react for 18h, filter, and dry the filter residue at 85°C to obtain the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 .

[0034] S2: the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 and lithium hydroxide were added to the mortar, and the grinding was continued for 40min, in which the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio of lithium hydroxide to lithium hydroxide is 1:1.12, and then placed in a tube furnace, the air is first evacuated with nitrogen, and then oxygen is introduced at a flow rate of 0.19L / min, and the temperature is raised to 360°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com