Power assembly rear suspension and clutch booster integrated support and rear suspension device

A technology of powertrain and booster, applied in the direction of power unit, control unit, jet propulsion unit, etc., can solve the problems of poor stability and large number of parts, and achieve the effect of improving stability and reducing the number of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

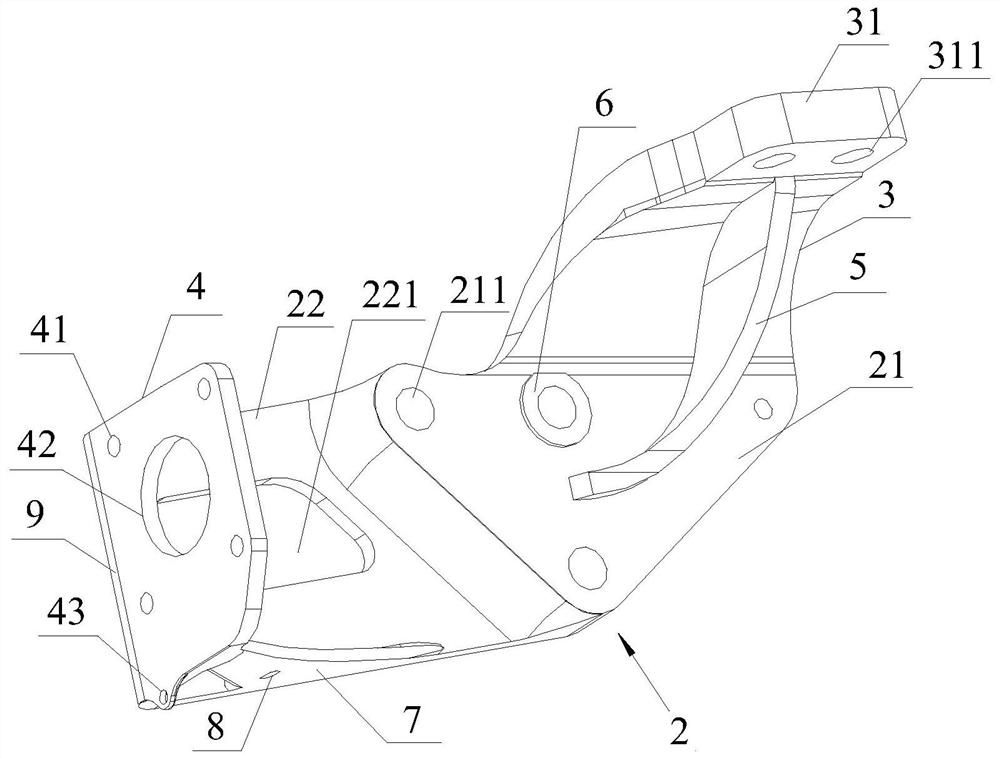

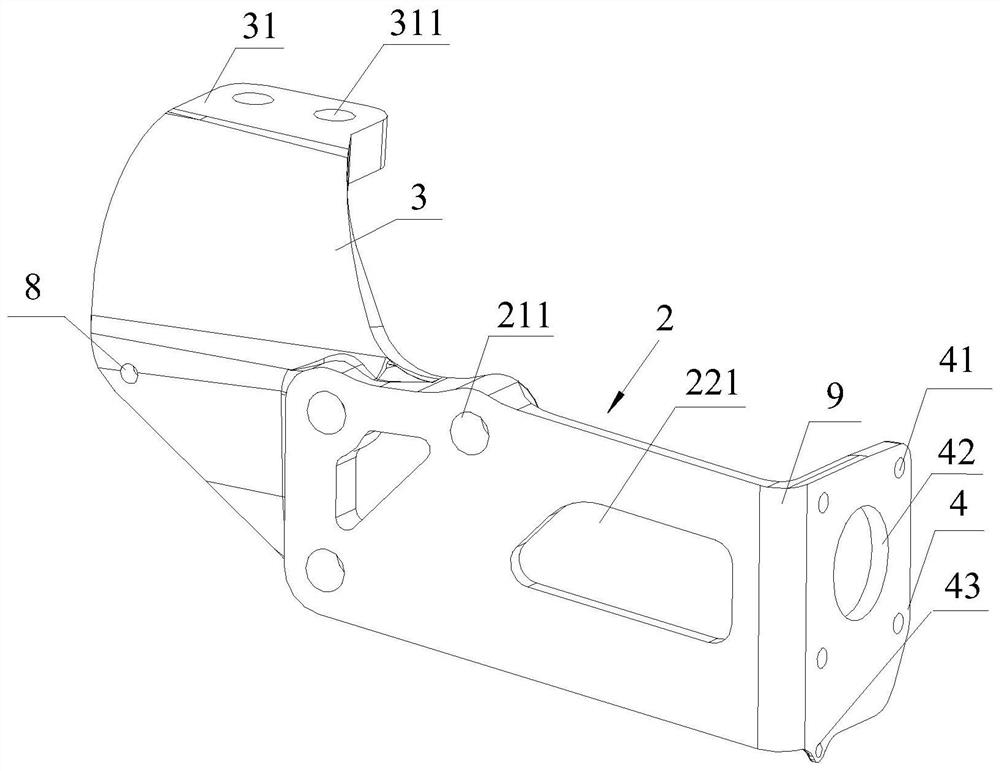

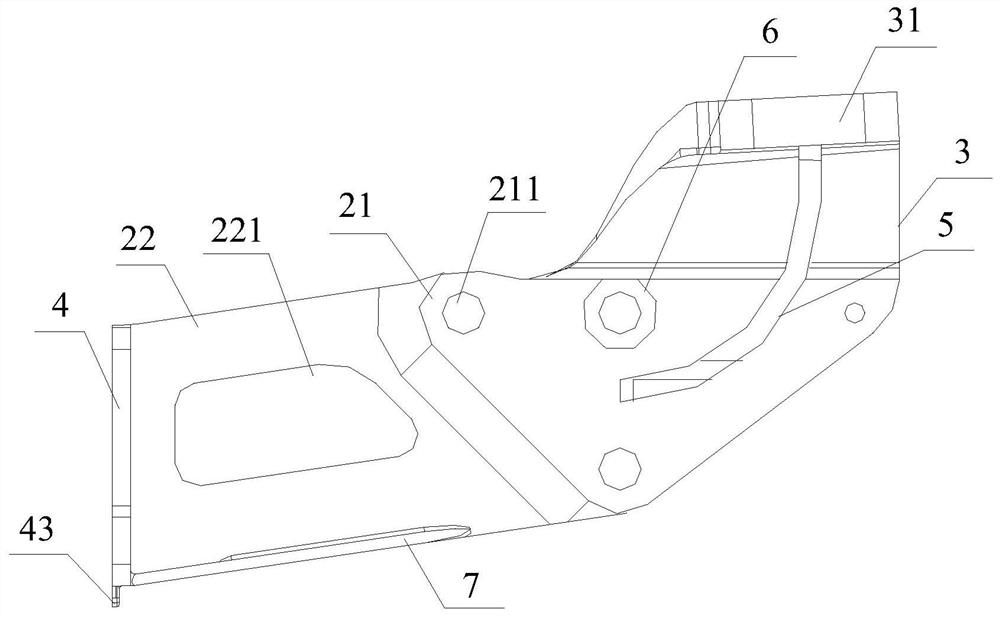

[0030] see Figure 1 to Figure 3 As shown, the embodiment of the present application provides a powertrain rear suspension and clutch booster integrated bracket, which includes a base 2, a variable-section connecting plate 3 and a fixing plate 4, and the base 2 includes a closely connected mounting plate 21 and an extension plate 22. The thickness of the extension plate 22 is lower than that of the mounting plate 21, and it is used to place the clutch booster 10. The mounting plate 21 is provided with a plurality of first mounting holes 211, and the number of the first mounting holes 211 is preferably three. The base 2 Installed on the side of the gearbox 1 through three first mounting holes 211 with a diameter of 18 mm, the height of the base 2 can be set to 105 mm, the width to 110 mm, and the thickness to 28 mm, and the three third bottom parts of the base 2 can be set to A part of the center of a mounting hole 211 is dug out to further reduce the weight of the bracket to a...

Embodiment 2

[0036] On the basis of embodiment 1:

[0037] see figure 1 As shown, the integrated bracket also includes a reinforced connecting plate 7, the reinforced connecting plate 7 is set to be arc-shaped and its rounded edge is also set to be arc-shaped, one side is connected with the extension plate 22, and the other side is connected with the fixed plate 4, That is, the extension plate 22 of the base 2 is fixedly connected to the fixed plate 4 through the reinforced connecting plate 7, which can disperse the stress between the extended plate 22 and the fixed plate 4, avoid stress concentration, and further strengthen the stability of the integrated bracket ; see figure 1 with figure 2 As shown, the reinforcing connecting plate 7 and the mounting plate 21 are provided with pipe clip fixing holes 8, and the pipe clip fixing holes 8 are used for fixing pipelines, so as to facilitate the wiring and arrangement of pipelines.

Embodiment 3

[0039] On the basis of embodiment 1:

[0040] see figure 2 As shown, the extension plate 22 of the base 2 is provided with a hollow structure 221, which is to hollow out part of the structure in the extension plate 22, so that there is no redundant material in the integrated bracket, and the hollow structure 221 can further play a role in weight reduction. function, and then realize the lightweight purpose of the integrated bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com