Preparation method and application of polyhydroquinone film coated ferrocobalt magnetic catalyst

A magnetic catalyst, cobalt-iron alloy technology, applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of difficult recovery of metal ions, Secondary pollution and other problems, to achieve the effect of rapid separation, easy separation and recovery, and easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 6mmol of cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) be dissolved in 40mL deionized water, add polyvinylpyrrolidone (PVP) of 5g / L, fully stir;

[0031] (2) Weigh 4mmol of potassium ferricyanide (K 3 [Fe(CN) 6 ])) was dissolved in 40 mL deionized water to obtain K 3 [Fe(CN) 6 ] solution, this solution is added dropwise in the cobalt chloride solution of step (1), after stirring for 30min, leave it to stand for aging for 24h to obtain the cobalt iron Prussian blue analogue Co 3 [Fe(CN) 6 ] 2 .

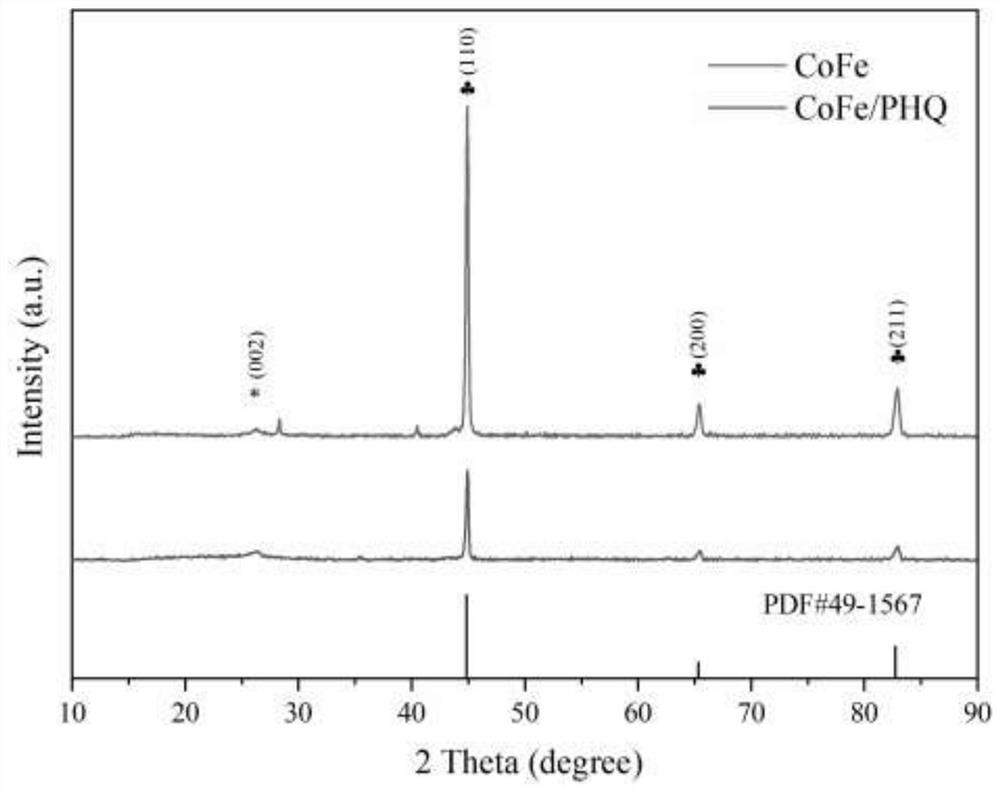

[0032] (3) will Co 3 [Fe(CN) 6 ] 2 After centrifugal separation and vacuum drying, it was placed in a muffle furnace for calcination at 600° C. (under nitrogen, heating rate 5° C. / min) for 2 hours to obtain cobalt-iron alloy magnetic powder.

[0033](4) Dissolve 0.8g of hydroquinone in ultrapure water, then add 0.4g of cobalt-iron alloy magnetic powder (mass ratio to PHQ is 1:2), and stir for 30min.

[0034] (5) within 1h, add 3mL of ferrous sulfate (FeSO 4...

Embodiment 2

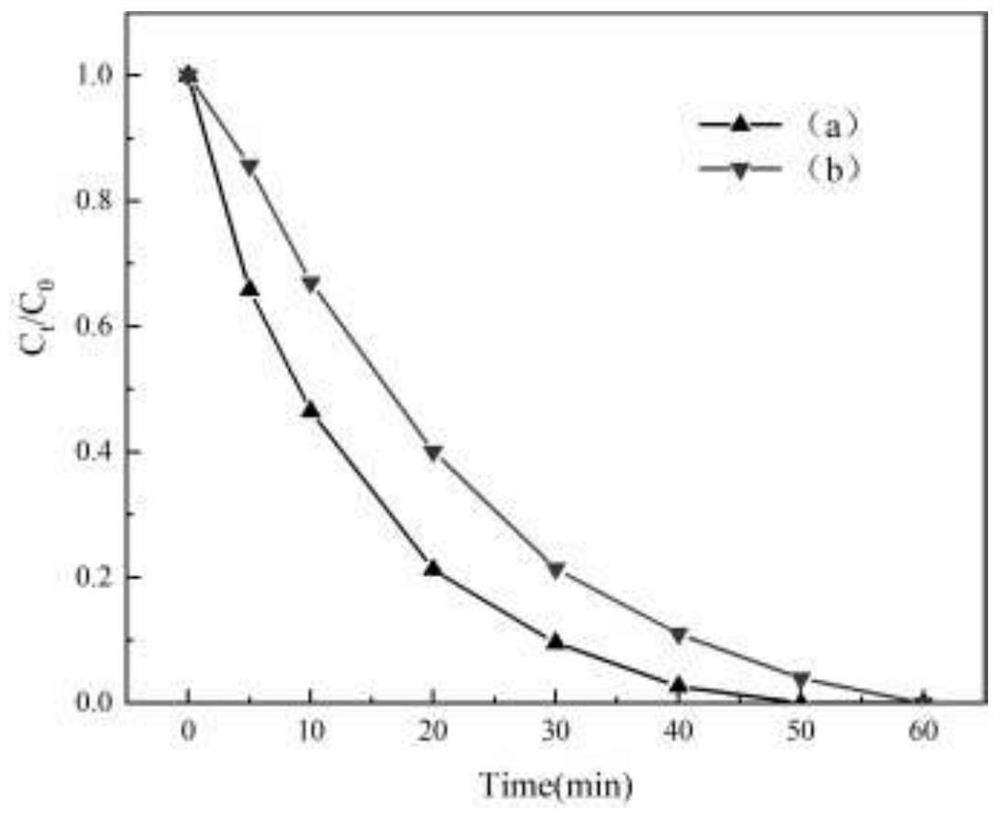

[0039] The difference between the preparation process of this example and Example 1 is that step (4) ensures that the mass ratio of cobalt-iron alloy magnetic powder to PHQ is 1:3, and other preparation steps are the same. The above-prepared CoFe / PHQ (1:3) was applied to PS and H 2 o 2 Advanced oxidation system removes ATZ. The degradation conditions are as in Example 1. The removal ability of PS advanced oxidation system ATZ is as follows: Figure 4 Shown in curve (a), reaction carries out 60min, and ATZ removal rate reaches 100%; H 2 o 2 The removal ability of advanced oxidation system ATZ is as follows: Figure 4 As shown in the curve (b), the removal rate of ATZ reached 89.3% after the reaction was carried out for 60 minutes.

Embodiment 3

[0041] The difference between the preparation process of this example and Example 1 is that step (4) ensures that the mass ratio of cobalt-iron alloy magnetic powder to PHQ is 1:1, and other preparation steps are the same. The above-prepared CoFe / PHQ (1:1) was applied to PS and H 2 o 2 Advanced oxidation system removes ATZ. The degradation conditions are as in Example 1. The removal ability of PS advanced oxidation system ATZ is as follows: Figure 5 Shown in curve (a), reaction carries out 60min, and ATZ removal rate reaches 100%; H 2 o 2 The removal ability of advanced oxidation system ATZ is as follows: Figure 5 As shown in the curve (b), the removal rate of ATZ reached 88.1% after the reaction was carried out for 60 minutes.

[0042] As can be seen from Example 1, Example 2, and Example 3, changing the mass ratio of cobalt-iron alloy magnetic powder and PHQ has a greater impact on the catalytic ability of the catalyst, and when the mass ratio is 1:2, PS and H 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com