Desulfurization method and device for blast furnace gas

A blast furnace gas and desulfurization device technology, which is applied to furnaces, gas dust removal, furnace components, etc., can solve the problems of low practicability, high operating costs, large investment, etc., and achieves high practicability, low operating costs, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

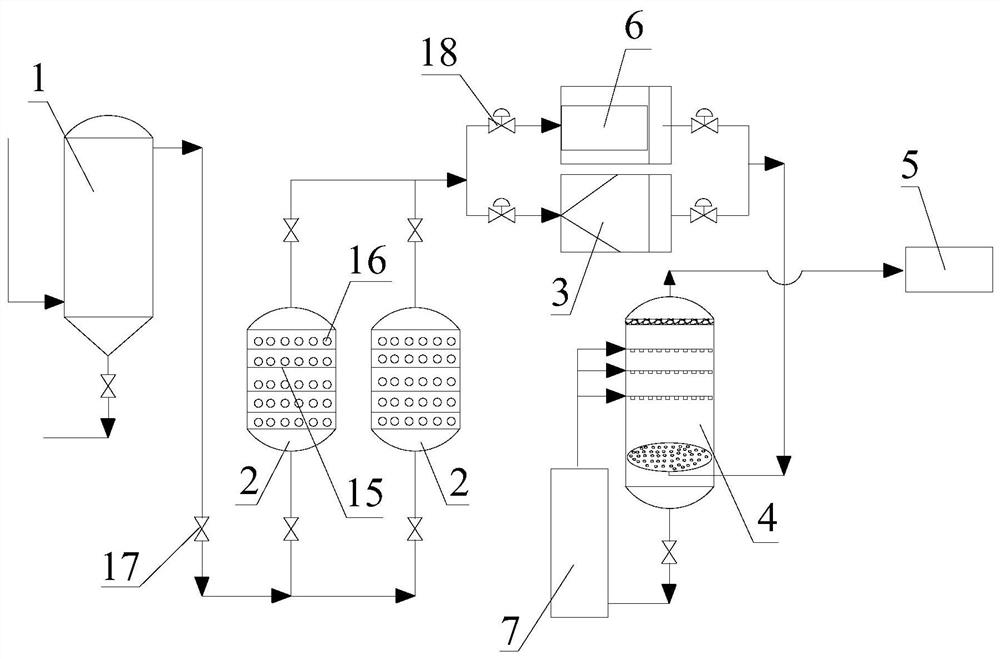

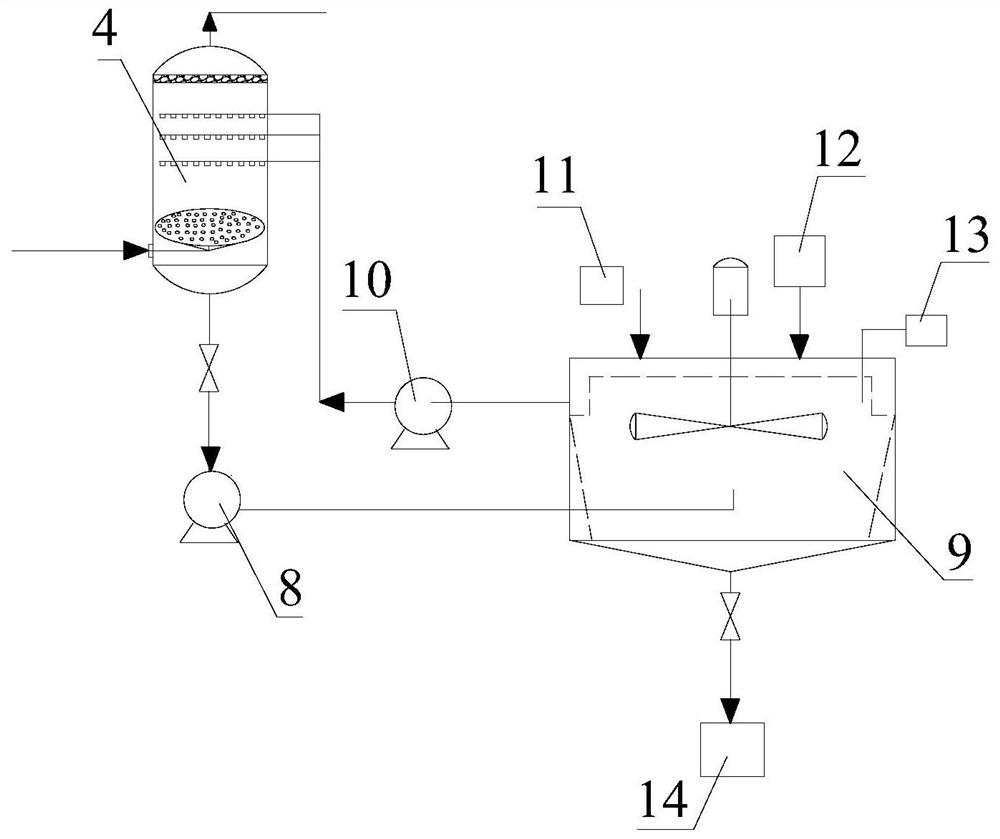

[0035] refer to figure 1 , figure 2 The shown blast furnace gas desulfurization process flow chart is carried out according to the following steps:

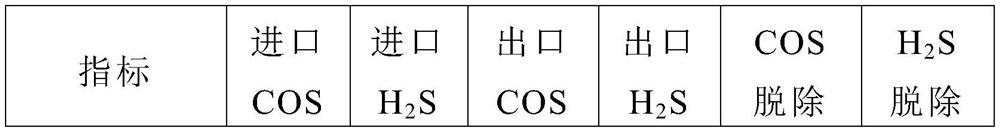

[0036] The temperature ~ 60 ℃ and pressure ~ 0.2MPa after fine dust removal by the bag filter 1 is sent to the parallel-connected hydrolysis catalytic tower 2 for hydrolysis catalytic desulfurization. The blast furnace gas is heated in the hydrolysis catalyst (γ-Al 2 O 3 As the carrier, the alkali metal K 2 Under the action of O is the active component catalyst), part of the COS is converted into H 2 S, the blast furnace gas is then depressurized by the blast furnace gas residual pressure turbine power generation device 3 or the pressure reducing valve 6 and then sent to the desulfurization cooling tower 4. In the desulfurization and cooling tower 4, the gas and the lye are in countercurrent contact, and an absorption reaction occurs, thereby completing the sulfide, HCl and CO in the gas. 2 The partial removal of acid gas c...

Embodiment 2

[0042] refer to figure 1 , figure 2 The shown blast furnace gas desulfurization process flow chart is carried out according to the following steps:

[0043] The temperature ~ 90 ℃ and pressure ~ 0.22MPa after being finely dedusted by the bag filter 1 are sent to the parallel-connected hydrolysis catalytic tower 2 for hydrolysis catalytic desulfurization. 2 As the carrier, the alkali metal K 2 Under the action of O is the active component catalyst), part of the COS is converted into H 2 S, the blast furnace gas is then depressurized by the blast furnace gas residual pressure turbine power generation device 3 or the pressure reducing valve 6 and then sent to the desulfurization cooling tower 4. In the desulfurization and cooling tower 4, the gas and the lye are in countercurrent contact, and an absorption reaction occurs, thereby completing the sulfide, HCl and CO in the gas. 2 The partial removal of acid gas can achieve the purpose of blast furnace gas purification. The g...

Embodiment 3

[0049] refer to figure 1 , figure 2 The shown blast furnace gas desulfurization process flow chart is carried out according to the following steps:

[0050] The temperature ~ 120 ℃ and pressure ~ 0.25MPa after the fine dust removal by the bag filter 1 is sent to the parallel connected hydrolysis catalytic tower 2 for hydrolysis catalytic desulfurization. The blast furnace gas is heated in the hydrolysis catalyst (ZrO 2 As the carrier, the alkali metal K 2 Under the action of O is the active component catalyst), part of the COS is converted into H 2 S, the blast furnace gas is then depressurized by the blast furnace gas residual pressure turbine power generation device 3 or the pressure reducing valve 6 and then sent to the desulfurization cooling tower 4. In the desulfurization and cooling tower 4, the gas and the lye are in countercurrent contact, and an absorption reaction occurs, thereby completing the sulfide, HCl and CO in the gas. 2 The partial removal of acid gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com