UV antibacterial and mildew-proof finish paint and preparation method thereof

An antibacterial, antifungal, and topcoat technology, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of UV coatings that are prone to aging and yellowing, and achieve improved color stability and less irritation Sexual odor, high efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

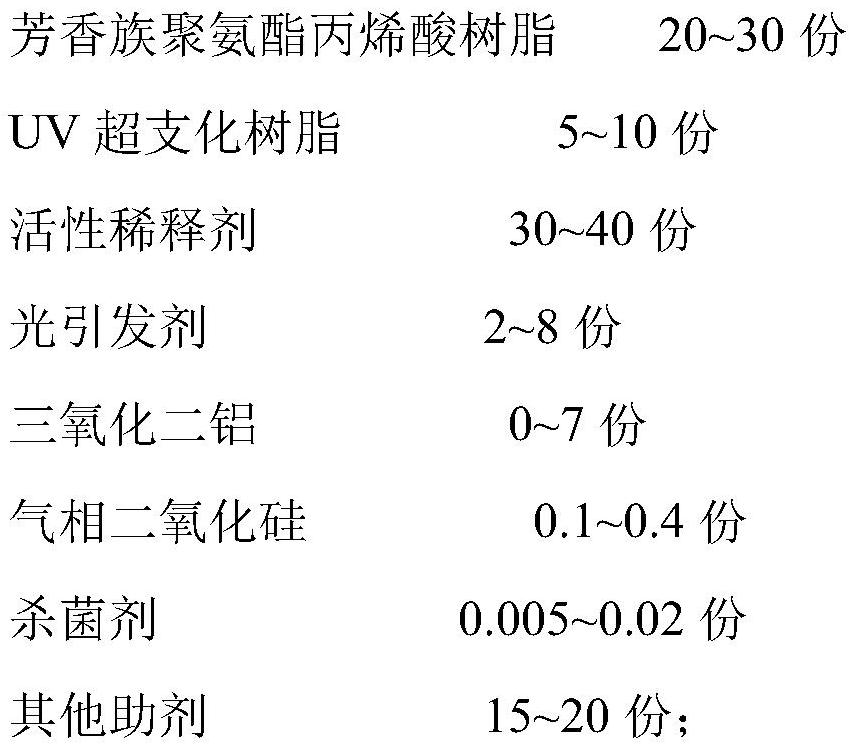

[0095] A kind of UV antibacterial mildew-proof finish paint, its preparation raw material composition and content are as follows:

[0096]

[0097] Above-mentioned reactive diluent is made up of DPGDA, TMPTA, HEMA and NPGDA, calculates by mass ratio, namely DPGDA: TMPTA: HEMA: NPGDA is 1:0.533:0.333:0.667 (15 parts: 8 parts: 5 parts: 10 parts); The above-mentioned photoinitiator is composed of TPO photoinitiator, 1173 photoinitiator and 1046 photoinitiator, calculated by mass ratio, that is, TPO photoinitiator: 1173 photoinitiator: 1046 photoinitiator is 1:4:5.6 (0.5 parts :2 copies: 2.8 copies);

[0098] Above-mentioned fungicide is isothiazolinone;

[0099] The above-mentioned other additives are composed of polyethylene wax, dispersant, matting agent, leveling agent, defoamer and sensitizer, and its composition is calculated by mass ratio, that is, polyethylene wax: dispersant: matting agent: leveling agent : Defoamer: Sensitizer 1:0.75:5.343:0.15:0.05:1.9 (2 parts: 1....

Embodiment 2

[0111] A kind of UV antibacterial mildew-proof finish paint, its preparation raw material composition and content are as follows:

[0112]

[0113]

[0114] Above-mentioned reactive diluent is made up of DPGDA, TMPTA, HEMA and NPGDA, calculates by mass ratio, namely DPGDA: TMPTA: HEMA: NPGDA is 1:0.534:0.334:0.667 (11.84 parts: 6.32 parts: 3.95 parts: 7.9 parts);

[0115] The above photoinitiator is composed of TPO photoinitiator, 1173 photoinitiator and 1046 photoinitiator, calculated by mass ratio, that is, TPO photoinitiator: 1173 photoinitiator: 1046 photoinitiator is 1:4:5 (0.2 parts : 0.8 copies : 1 copies);

[0116] Above-mentioned fungicide is isothiazolinone;

[0117] The above-mentioned other additives are composed of polyethylene wax, dispersant, matting agent, leveling agent, defoamer and sensitizer, and its composition is calculated by mass ratio, that is, polyethylene wax: dispersant: matting agent: leveling agent : Defoamer: Sensitizer 1:0.75:3.75:0.05:0...

Embodiment 3

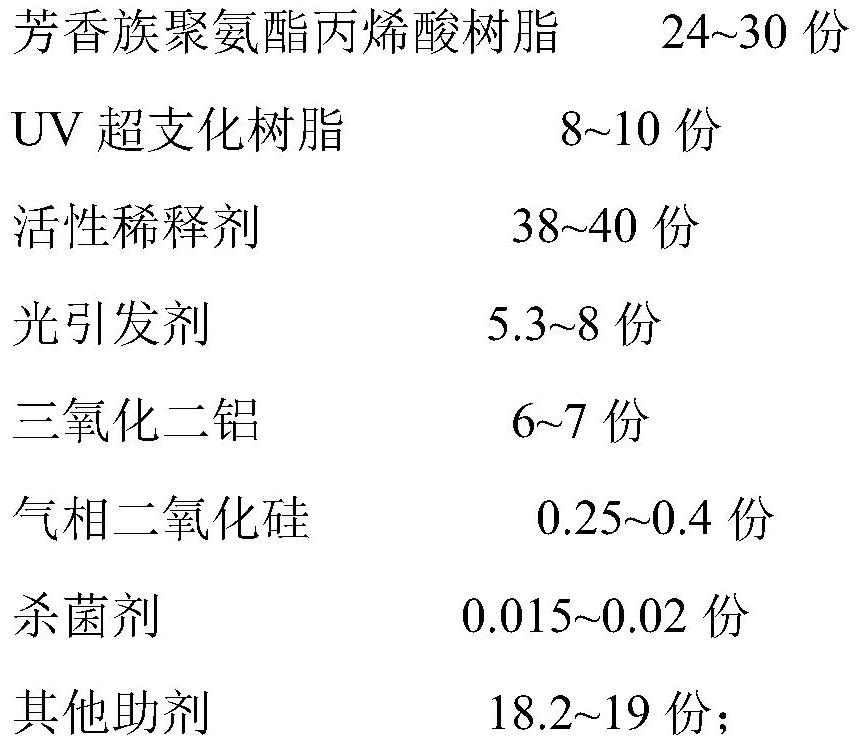

[0129] A kind of UV antibacterial mildew-proof finish paint, its preparation raw material composition and content are as follows:

[0130]

[0131]Above-mentioned reactive diluent is made up of DPGDA, TMPTA, HEMA and NPGDA, calculates by mass ratio, namely DPGDA: TMPTA: HEMA: NPGDA is 1:0.534:0.333:0.667 (15.75 parts: 8.41 parts: 5.25 parts: 10.5 parts);

[0132] The above-mentioned photoinitiator is composed of TPO photoinitiator, 1173 photoinitiator and 1046 photoinitiator, calculated by mass ratio, that is, TPO photoinitiator: 1173 photoinitiator: 1046 photoinitiator is 1:3:4 (1 part :3 copies: 4 copies);

[0133] Above-mentioned fungicide is isothiazolinone;

[0134] The above-mentioned other additives are composed of polyethylene wax, dispersant, matting agent, leveling agent, defoamer and sensitizer, and its composition is calculated by mass ratio, that is, polyethylene wax: dispersant: matting agent: leveling agent : Defoamer: Sensitizer 1:1.15:5.25:0.15:0.05:1.9 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com