Starch-based polymer composite flocculant for sewage treatment and preparation method thereof

A composite flocculant and polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high cost of use and poor effect of wastewater treatment, and achieve the effect of low cost, good decolorization, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

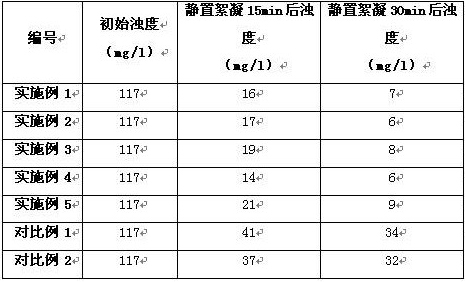

Examples

Embodiment 1

[0034] (a). Potato peels are dried and pulverized and passed through a 100-mesh sieve, and the under-sieve is taken to obtain potato peel powder, and 500g of potato peel powder is added to distilled water to prepare a suspension to obtain a potato peel starch suspension;

[0035] (b). Adding a concentration of 1 mol / L NaOH solution 1L to the potato peel starch suspension prepared in step (a) activates the chemical functional groups of the potato peel powder to obtain solution A;

[0036] (c). Add 50 g of hexamethylenediamine to solution A in step (b) and react at 40°C for 1.5 hours to obtain solution B;

[0037] (d). Add 10 g of cross-linking agent dimethyl diallyl ammonium chloride and 2 g of initiator potassium persulfate to the solution B prepared in step (c), react at 30°C for 2 hours, and then add The total mass of 0.5% polyaluminum chloride is fully stirred evenly and dried to obtain a starch-based polymer composite flocculant product.

Embodiment 2

[0039] (a). Potato peels are dried and pulverized and passed through a 100-mesh sieve, and the under-sieve is taken to obtain potato peel powder, and 500g of potato peel powder is added to distilled water to prepare a suspension to obtain a potato peel starch suspension;

[0040] (b). Adding 0.5L of NaOH solution with a concentration of 2mol / L to the potato peel starch suspension prepared in step (a) to activate the chemical functional groups of the potato peel powder to obtain solution A;

[0041] (c). Add 60 g of hexamethylenediamine to solution A in step (b) and react at 40°C for 1.5 hours to obtain solution B;

[0042] (d). Add 12 g of cross-linking agent dimethyl diallyl ammonium chloride and 2 g of initiator potassium persulfate to the solution B prepared in step (c), react at 30°C for 2 hours, and then add The total mass of 0.5% polyaluminum chloride is fully stirred evenly and dried to obtain a starch-based polymer composite flocculant product.

Embodiment 3

[0044] (a). Potato peels are dried and pulverized and passed through a 100-mesh sieve, and the under-sieve is taken to obtain potato peel powder, and 500g of potato peel powder is added to distilled water to prepare a suspension to obtain a potato peel starch suspension;

[0045] (b). Adding 0.5L of NaOH solution with a concentration of 1mol / L to the potato peel starch suspension prepared in step (a) to activate the chemical functional groups of the potato peel powder to obtain solution A;

[0046] (c). Add 80 g of hexamethylenediamine to solution A in step (b) and react at 40°C for 1.5 hours to obtain solution B;

[0047] (d). Add 20 g of cross-linking agent dimethyl diallyl ammonium chloride and 2 g of initiator potassium persulfate to solution B prepared in step (c), react at 30°C for 2 hours, and then add The total mass of 0.5% polyaluminum chloride is fully stirred evenly and dried to obtain a starch-based polymer composite flocculant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com