Refining method of omeprazole

A technology of omeprazole and a purification method is applied in the field of purification of 5-methoxy-2-[[methyl]sulfinyl]-1H-benzimidazole, and can solve the problem of low dispersibility of omeprazole , unsuitable for industrial production, large amount of impurities in omeprazole, etc., to reduce the risk of increased impurities, facilitate pH adjustment, and improve the effect of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Omeprazole refining process:

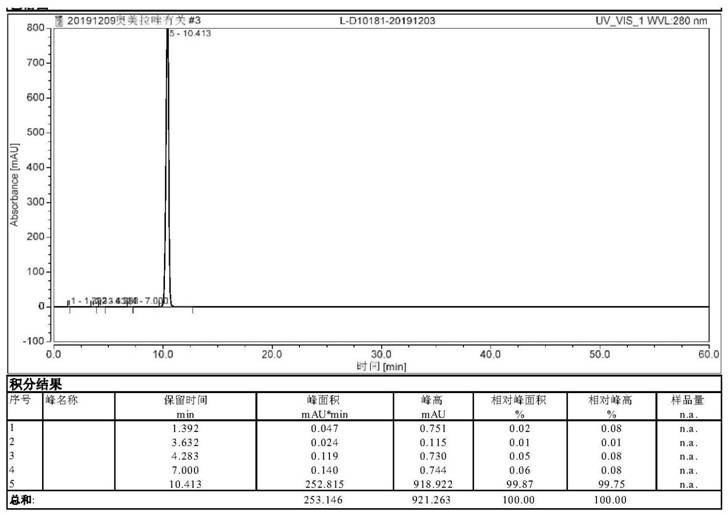

[0038] Step 1: Pump 5.0kg of purified water into a 20L reaction kettle, then put 2.0kg of sodium hydroxide into the kettle, and stir at room temperature until it dissolves. Drop into omeprazole crude product 1.0kg (HPLC:98.5%, as figure 1 ), stirred at room temperature until dissolved. Pump 2.5kg of dichloromethane into the kettle, stir at room temperature for 15±5 minutes, let stand and separate the liquid, the dichloromethane phase enters the waste water bucket, and the upper water layer is added to the clean reaction kettle. Add 30g of EDTA and 36g of sodium dithionite to the water layer.

[0039] Step 2: Pump 5 kg of dichloromethane into the water phase kettle, and adjust the pH to 8.5 with sodium bicarbonate. After pH adjustment, let stand and separate liquids. The aqueous phase was extracted with 2 kg of dichloromethane. The upper aqueous phase enters the waste water tank, and the organic phase is combined and pumped into a clea...

Embodiment 2

[0042] Step 1: Pump 6.0kg of purified water into a 20L reaction kettle, then put 2.7kg of sodium carbonate into the kettle, and stir at room temperature until it dissolves. Drop into omeprazole crude product 1.0kg (HPLC:98.5%, as figure 1 ), stirred at room temperature until dissolved. Pump 3kg of ethyl acetate into the kettle, stir at room temperature for 15±5 minutes, let it stand and separate the liquid, the ethyl acetate phase enters the waste water bucket, and the upper water layer is added to the clean reaction kettle. Add 30g of EDTA and 18g of sodium dithionite to the water layer.

[0043] Step 2: Pump 5 kg of dichloromethane into the water phase kettle, and adjust the pH to 7.0 with glacial acetic acid. After pH adjustment, let stand and separate liquids. The aqueous phase was extracted with 2 kg of dichloromethane. The upper aqueous phase enters the waste water tank, and the organic phase is combined and pumped into a clean reactor.

[0044] Step 3: Control the ...

Embodiment 3

[0046]Step 1: Pump 5.0kg of purified water into a 20L reaction kettle, then put 2.8kg of potassium hydroxide into the kettle, stir at room temperature until dissolved. Drop into omeprazole crude product 1.0kg (HPLC:98.5%, as figure 1 ), stirred at room temperature until dissolved. Pump 3kg of toluene into the kettle, stir at room temperature for 15±5 minutes, let stand and separate the liquid, the toluene phase enters the waste water bucket, and the upper water layer is added to the clean reaction kettle. 15g of EDTA, 17g of tetrasodium ethylenediaminetetraacetic acid, and 72g of sodium dithionite were added to the water layer.

[0047] Step 2: Pump 5 kg of dichloromethane into the water phase kettle, and adjust the pH to 7.5 with glacial acetic acid. After pH adjustment, let stand and separate liquids. The aqueous phase was extracted with 2 kg of dichloromethane. The upper aqueous phase enters the waste water tank, and the organic phase is combined and pumped into a clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com