Manufacturing method of medical instrument detection plate

A technology of medical equipment and manufacturing method, which is applied in the field of circuit boards, can solve problems such as the insulation of the solder barrier layer is easy to fall off, and achieve the effects of high product value, strong competitiveness, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0033] A method for manufacturing a medical instrument detection board, comprising the following steps:

[0034] (1) Cutting, cutting the base material according to the preset size;

[0035] (2) Inner layer graphics and inner layer etching; complete the inner layer circuit production, and then conduct internal inspection to screen out unqualified products;

[0036] (3) The multi-layer substrate is pressed into a whole board, and then drilled after lamination, and then copper sinking or plate electrical is carried out to realize the electrical conduction of the multi-layer substrate;

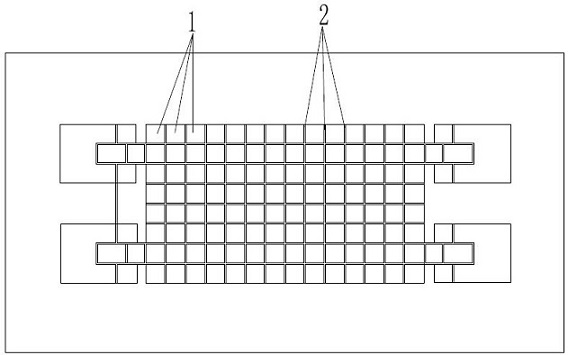

[0037] (4) Circuit pattern (1), etching (1): make circuit pattern (1) by pressing dry film, exposure and development, the entire board is provided with pads 1 arranged in arrays, and etching will etch out the pad spacing 2, Pad spacing 2 is the solder-proof area betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com