Simulation method for multi-gate-finger gallium nitride device electric heating joint modeling

A technology of gallium nitride device and simulation method, which is applied in the fields of instruments, electrical digital data processing, special data processing applications, etc. The effect of improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A simulation method for electrothermal joint modeling of a multi-gate finger gallium nitride device according to the present invention, the following steps are performed in sequence:

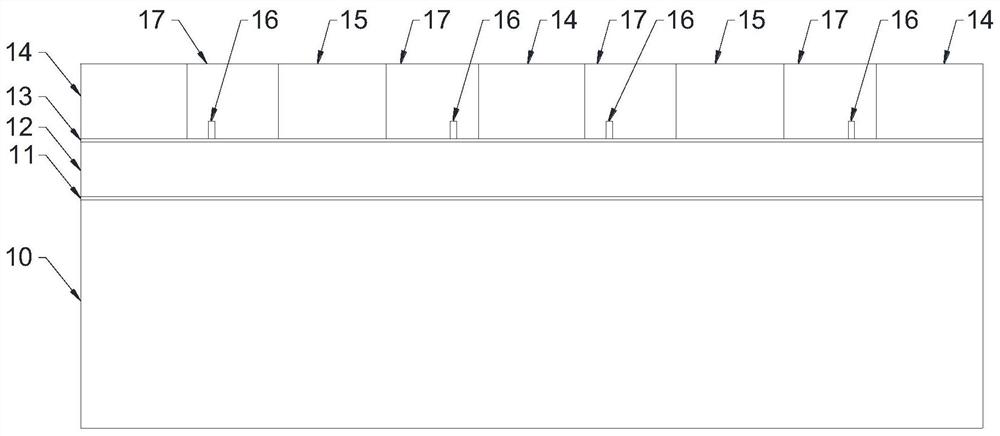

[0024] First, a two-dimensional model structure of a GaN device with multiple gate fingers is constructed. The so-called multi-gate finger refers to a device structure with 2N gate indices, where N is a natural number, that is, the minimum gate index is two.

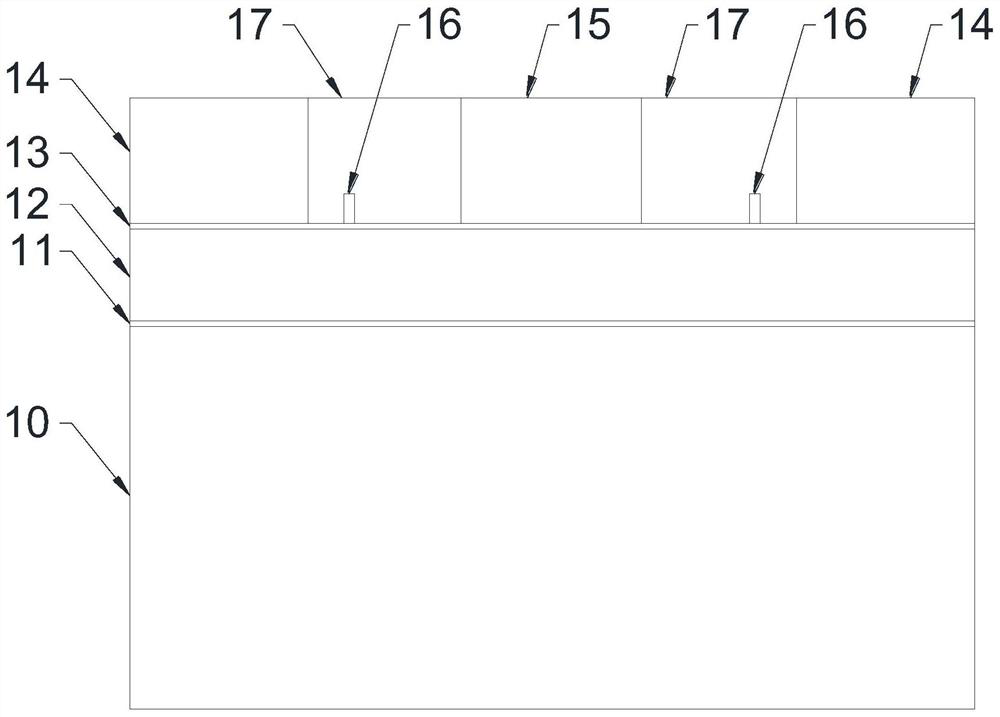

[0025] The structure of the two-dimensional model with grid index two is as follows figure 1 As shown, a substrate 10 , an aluminum nitride layer 11 , a gallium nitride layer 12 , and an aluminum gallium nitride layer 13 are stacked from bottom to top. A source 14 is arranged at both ends of the upper surface of the aluminum gallium nitride layer 13 , and a drain 15 is arranged in the middle. A gate 16 is respectively arranged between the two source electrodes 14 and the drain electrodes 15 , and the gate electrodes 16 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com