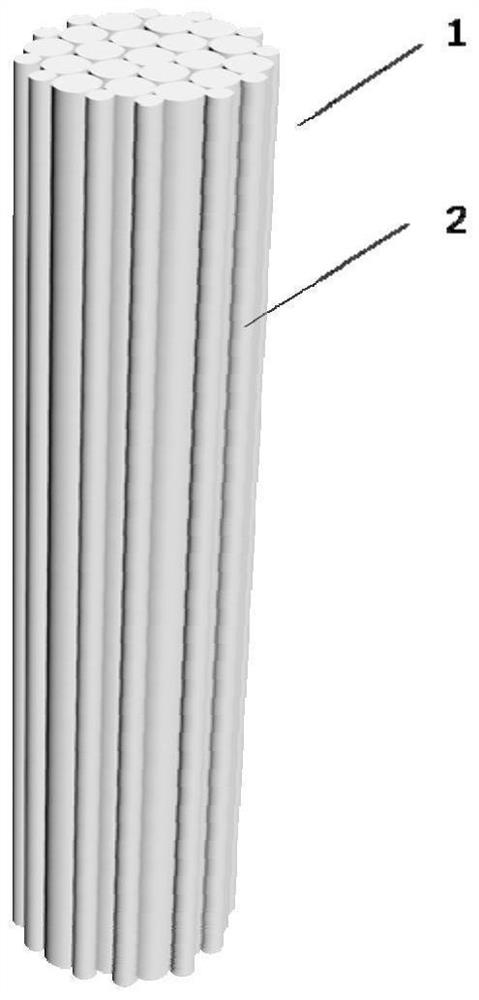

A kind of wood spring and preparation method thereof

A wood and lignin technology, used in springs, wood processing appliances, manufacturing tools, etc., can solve the problems of difficult interaction, complex fiber force, limited elastic limit of wood, etc., and achieve a wide range of elasticity and improved fatigue limit. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

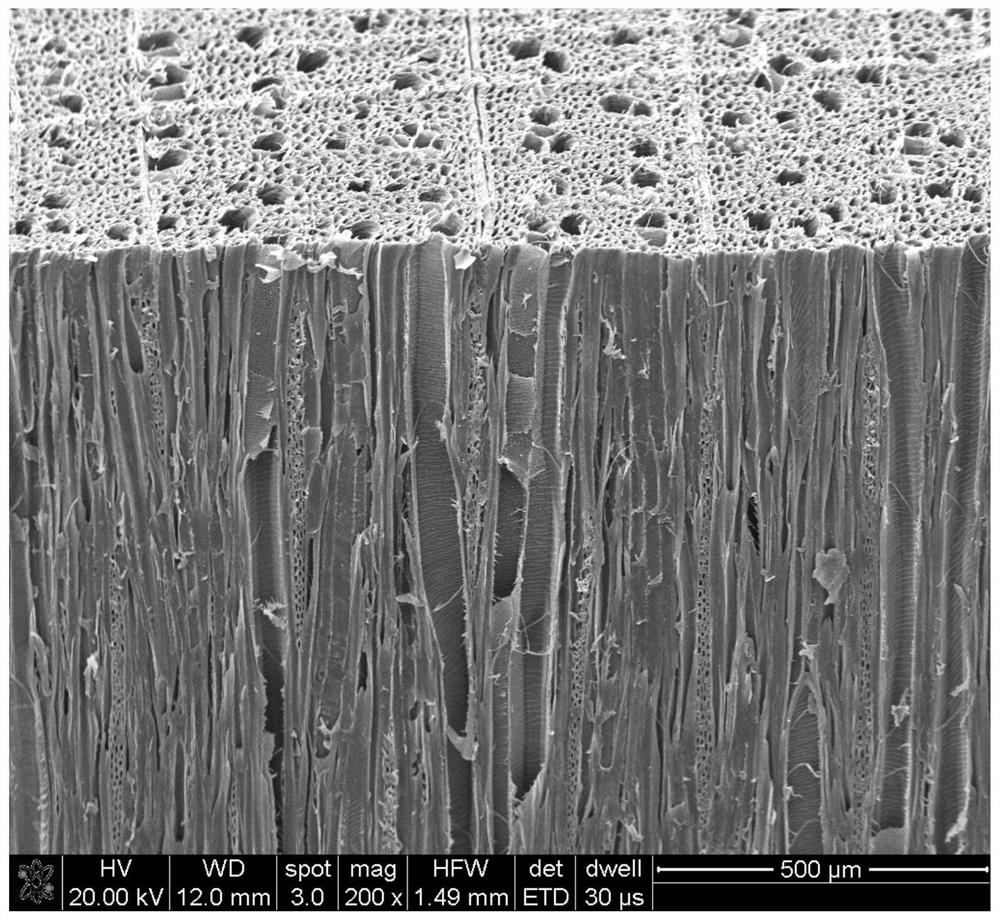

Method used

Image

Examples

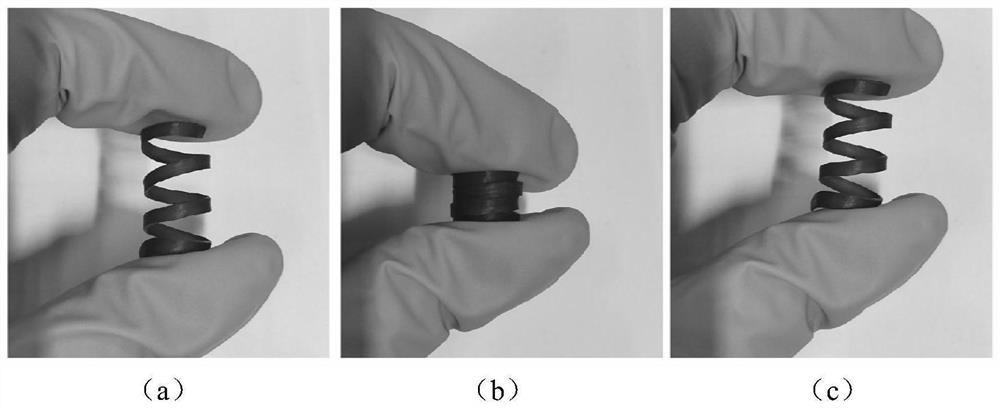

Embodiment 1

[0031] The basswood with a height of 30 cm and a diameter of 1 mm was placed in a 2.0 mol / L sodium hydroxide and 0.03 mol / L sodium sulfite aqueous solution for 10 hours, and the excess chemicals were washed with water and dried. Then placed in N,N-dimethylacetamide solution, 165℃, kept for 40 minutes, then cooled to 110℃, added a certain amount of lithium chloride, lithium chloride: the mass of N,N-dimethylacetamide solution Ratio=1:8, react for 40 minutes, after taking out, stand for 24 hours, immerse in water for 10 hours, then wash with deionized water for many times, then roll, shape and dry into a wood coil spring, with a tensile strength along the grain of 422MPa. The wood spring prepared in this example is as figure 2 As shown, it can be seen that it has a good elastic function and can replace the industrial application of metal springs.

Embodiment 2

[0033] Basswood with a height of 30cm, a length of 2mm and a thickness of 1mm was placed in 30% hydrogen peroxide and boiled for 2 hours, and the excess chemicals were washed with water, and then dried. Then placed in N,N-dimethylacetamide solution, 160℃, kept for 30 minutes, then cooled to 110℃, added a certain amount of lithium chloride, lithium chloride:N,N-dimethylacetamide solution=1 : 9, react for 60 minutes, after taking it out, let it stand for 10 hours, after taking it out, immerse it in water for 5 hours, then wash it with deionized water for many times, then roll it, shape it and dry it into a wood spiral compression spring, and its tensile strength along the grain is about 375MPa.

Embodiment 3

[0035] The pine sylvestris with a height of 30cm and a diameter of 1mm was cooked in water at high temperature and pressure for 10 hours, washed with water and then dried. The sample was placed in lithium chloride / DMAc=8g: 100ml solution and mixed, and reacted at a temperature of 165°C for 60min. The obtained mixed system was allowed to stand for 10 hours, then washed with deionized water for several times, then rolled, shaped and dried to form a wood helical tension spring with a tensile strength along the grain of about 401 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com