Method for recovering cobalt, copper and iron from waste cobalt-containing lithium ion battery

A lithium-ion battery and ion battery technology, applied in the field of metallurgy, can solve problems such as unrecoverable metal elements, difficult use of heat, and complicated process flow, and achieve excellent magnetic and physical and chemical properties, reduce slag viscosity, and short process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

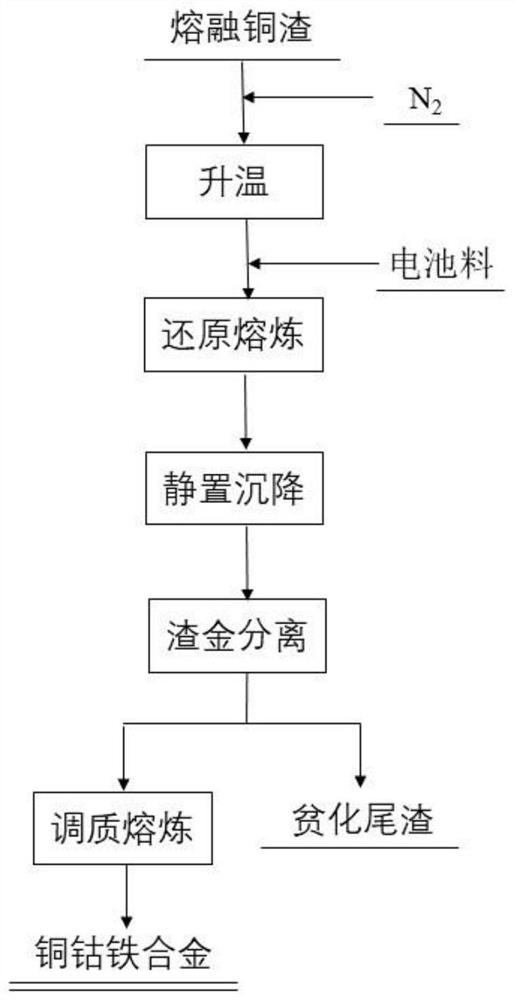

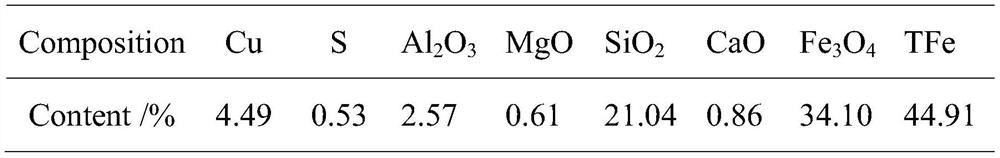

[0058] (1) 60g of molten copper slag produced by the rotary furnace at a temperature of 1200-1250°C is introduced into the depletion furnace, and N 2 Control the atmosphere, the purpose is to prevent O in the air 2 Interfering with the reduction smelting atmosphere, the gas flow rate is 200ml / min, and the molten copper slag is heated to 1400°C at a heating rate of 8°C / min, so that part of the Fe in the slag 3 o 4 Decomposed into FeO and Fe 2 o 3 .

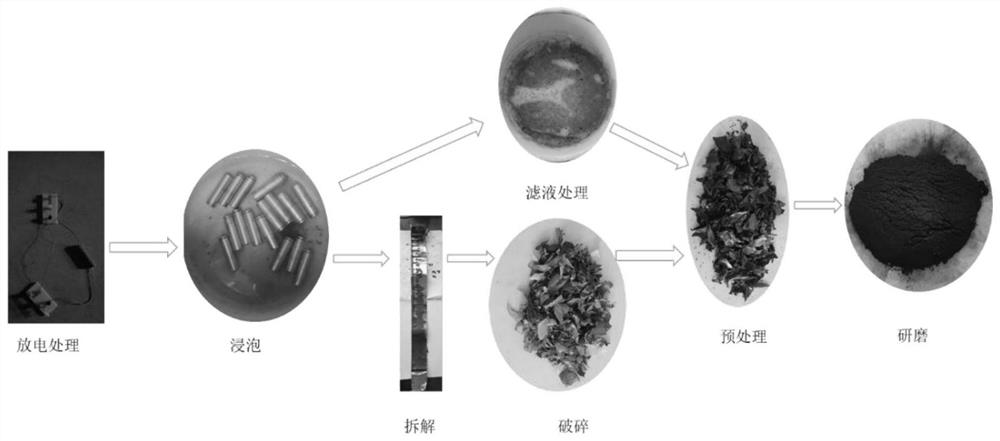

[0059] (2) Pretreatment of waste lithium cobalt oxide battery electrode materials: physical discharge - immersion inactivation treatment - disassembly after drying - crushing - pre-calcination at 200 ° C - grinding to 160 mesh.

[0060] (3) Grind the positive and negative electrode materials of 10g waste lithium cobaltate lithium ion battery after pretreatment to 160 mesh, and use N 2 The carrier gas is sprayed to the upper layer of the slag through the powder injection device for reduction smelting. The injection flow rate is...

Embodiment 2

[0063] (1) 160g of molten copper slag produced by the rotary furnace at a temperature of 1200-1250°C is introduced into the depletion furnace, and N 2 Control the atmosphere, the purpose is to prevent O in the air 2 Interfering with the reducing smelting atmosphere, the gas flow rate is 200ml / min, and the molten copper slag is heated to 1450°C at a heating rate of 10°C / min, so that part of the Fe in the slag 3 o 4 Decomposed into FeO and Fe 2 o 3 .

[0064] (2) Pretreatment of waste lithium cobalt oxide battery electrode materials: physical discharge - immersion inactivation treatment - disassembly after drying - crushing - pre-calcination at 200 ° C - grinding to 160 mesh.

[0065] (3) Grind the positive and negative electrode materials of 10g waste lithium cobaltate lithium ion battery after pretreatment to 160 mesh, and use N 2 The carrier gas is sprayed to the upper layer of the slag through the powder injection device for reduction smelting. The injection flow rate i...

Embodiment 3

[0068] (1) 60g of molten copper slag produced by the rotary furnace at a temperature of 1200-1250°C is introduced into the depletion furnace, and N 2 Control the atmosphere, the purpose is to prevent O in the air 2 Interfering with the reducing smelting atmosphere, the gas flow rate is 200ml / min, and the molten copper slag is heated to 1500°C at a heating rate of 10°C / min, so that part of the Fe in the slag 3 o 4 Decomposed into FeO and Fe 2 o 3 .

[0069] (2) Pretreatment of waste lithium cobalt oxide battery electrode materials: physical discharge - immersion inactivation treatment - disassembly after drying - crushing - pre-calcination at 200 ° C - grinding to 160 mesh.

[0070] (3) Grind the positive and negative electrode materials of 8.6g waste lithium cobaltate lithium ion battery after pretreatment to 160 mesh, and use N 2 The carrier gas is sprayed to the upper layer of the slag through the powder injection device for reduction smelting. The injection flow rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com