Mixed oil hydrogenation micro-interface enhanced reaction system and method

A technology of hydrogenation reaction and reaction system, applied in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve the problem of high hydrogen energy consumption, achieve low process severity, sufficient and stable emulsification and mixing, and reduce material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

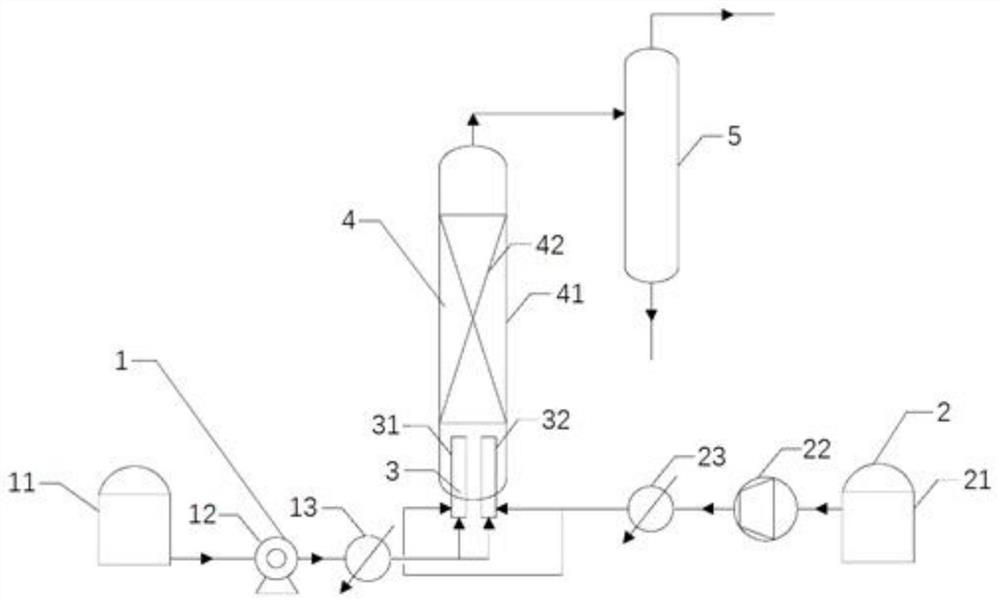

Embodiment 1

[0101] In this embodiment, the standard volume ratio of hydrogen and mixed oil in the first micro-interface generator is 0.45:1; the standard volume ratio of hydrogen and mixed oil in the micro-interface generator is 600:1; the average diameter of the microbubbles is greater than or equal to 1μm, less than 1mm microbubbles; the air pressure inside the fixed reactor 4 is controlled at 0.8MPa; the reaction temperature is controlled at 300°C; the catalyst is iron-molybdenum catalyst; the space velocity is controlled at 1h -1 . Test results: the sulfur content in raw gasoline before treatment was 110ppm, and the sulfur content in the treated mixed oil after treatment dropped to 35ppm.

Embodiment 2

[0103] In this example, the standard volume ratio of hydrogen to mixed oil in the first microinterface generator is 0.20:1; the standard volume ratio of hydrogen to mixed oil in the second microinterface generator is 655:1; the average diameter of microbubbles Microbubbles greater than or equal to 1μm and less than 1mm; the air pressure inside the fixed reactor 4 is controlled at 1MPa; the reaction temperature is controlled at 330°C; the catalyst is iron-cobalt catalyst; the space velocity is controlled at 3h -1 . Test results: the sulfur content in raw gasoline before treatment was 110ppm, and the sulfur content in the treated mixed oil after treatment dropped to 43ppm.

Embodiment 3

[0105] In this example, the standard volume ratio of hydrogen to mixed oil in the first microinterface generator is 0.35:1; the standard volume ratio of hydrogen to mixed oil in the second microinterface generator is 720:1; the average diameter of microbubbles Microbubbles greater than or equal to 1μm and less than 1mm; the air pressure inside the fixed reactor 4 is controlled at 1.2MPa; the reaction temperature is controlled at 350°C; the catalyst is a molybdenum-nickel catalyst; the space velocity is controlled at 6.5h -1 . Test results: the sulfur content in raw gasoline before treatment was 110ppm, and the sulfur content in the treated mixed oil dropped to 38ppm after treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com