Method for reducing acidity of isooctyl nitrate synthesized by taking waste acid as raw material

A technology of isooctyl nitrate and raw materials, which is applied in the field of refining isooctyl nitrate with high acidity, can solve the problems of low cost and high acidity of isooctyl nitrate, and achieve the effects of low cost, easy decomposition, and reduced acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

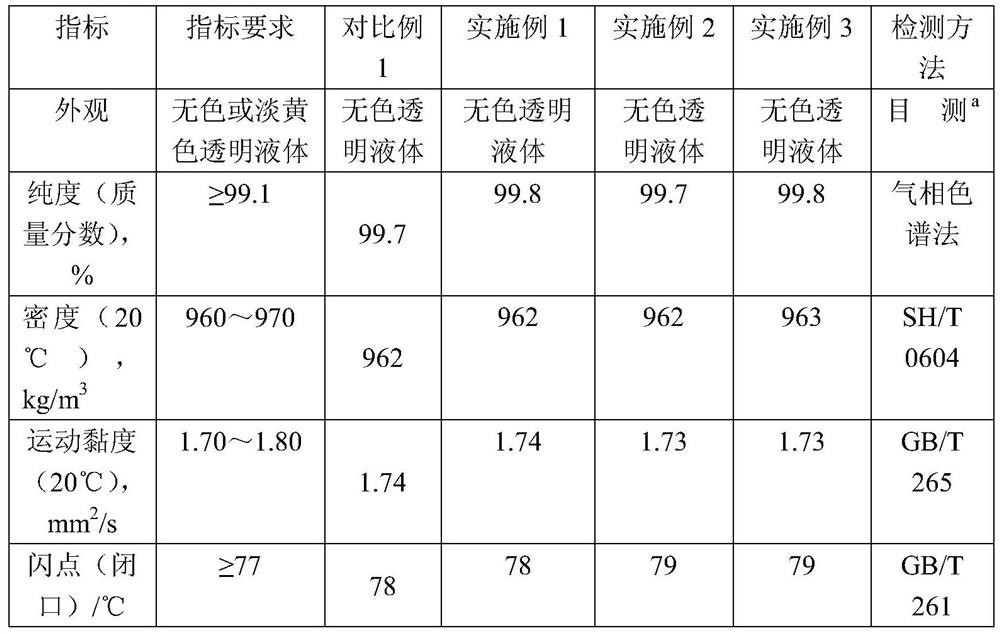

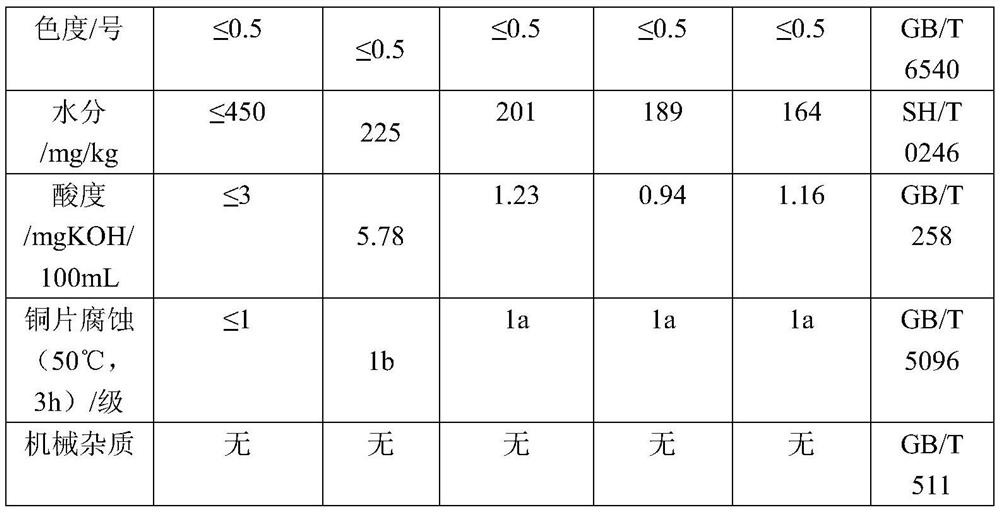

Embodiment 1

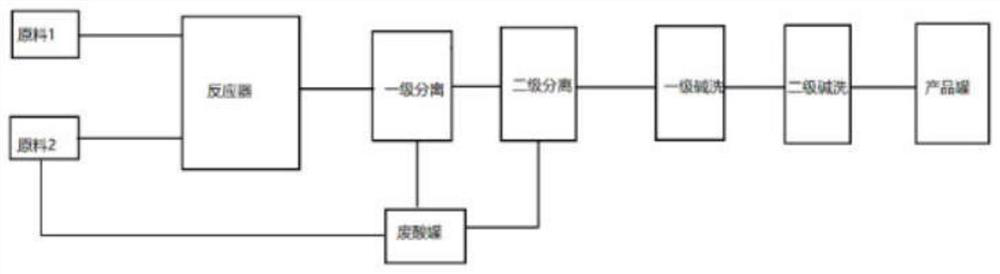

[0023] A kind of method that reduces taking spent acid as raw material synthetic isooctyl nitrate acidity:

[0024] (1) Configuration of mixed acid: with reused waste acid, 98% sulfuric acid, 98% nitric acid as raw material, configure mixed acid according to reused waste acid: 98% sulfuric acid: 98% nitric acid=1.8:1.2:1 (mass ratio), to be use;

[0025] (2) Set the reaction temperature to 15°C, and put the mixed acid and isooctyl alcohol into the microchannel reactor through the feed pump according to the molar ratio of 1.02:1 to react.

[0026] (3) A liquid separation tank is installed at the outlet of the reactor, and the reaction product enters the liquid separation tank. The crude ester enters the crude ester tank from the upper opening of the liquid separation tank, and the waste acid enters the waste acid secondary separation through the U-shaped pipe at the bottom of the liquid separation tank. Can.

[0027] (4) The crude ester in the secondary separation tank enters...

Embodiment 2

[0032] A kind of method that reduces taking spent acid as raw material synthetic isooctyl nitrate acidity:

[0033] (1) Configuration of mixed acid: with reused waste acid, 98% sulfuric acid, 98% nitric acid as raw materials, configure mixed acid according to reused waste acid: 98% sulfuric acid: 98% nitric acid=3:0.6:1 (mass ratio), to be use;

[0034] (2) Set the reaction temperature to 25°C, and put the mixed acid and isooctyl alcohol into the microchannel reactor through the feed pump according to the molar ratio of 1.1:1 to react.

[0035] (3) A liquid separation tank is installed at the outlet of the reactor, and the reaction product enters the liquid separation tank. The crude ester enters the crude ester tank from the upper opening of the liquid separation tank, and the waste acid enters the waste acid secondary separation through the U-shaped pipe at the bottom of the liquid separation tank. Can.

[0036] (4) The crude ester in the secondary separation tank enters t...

Embodiment 3

[0041] A kind of method that reduces taking spent acid as raw material synthetic isooctyl nitrate acidity:

[0042] (1) Configuration of mixed acid: with reused waste acid, 98% sulfuric acid, 98% nitric acid as raw material, configure mixed acid according to reused waste acid: 98% sulfuric acid: 98% nitric acid=2.2:1.2:1 (mass ratio), to be use;

[0043] (2) Set the reaction temperature to 20°C, put the mixed acid and isooctyl alcohol into the microchannel reactor through the feed pump according to the molar ratio of 1.05:1 to react.

[0044] (3) A liquid separation tank is installed at the outlet of the reactor, and the reaction product enters the liquid separation tank. The crude ester enters the crude ester tank from the upper opening of the liquid separation tank, and the waste acid enters the waste acid secondary separation through the U-shaped pipe at the bottom of the liquid separation tank. Can.

[0045] (4) The crude ester in the secondary separation tank enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com