Single-component modified geopolymer and application thereof

A geopolymer and one-component technology, applied in the field of one-component modified geopolymers, can solve the problems of failure to eliminate hidden dangers of quality, high requirements for construction operations, and blockage of grouting equipment, etc., and achieve simple structure and solidification Slow speed, reducing the effect of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

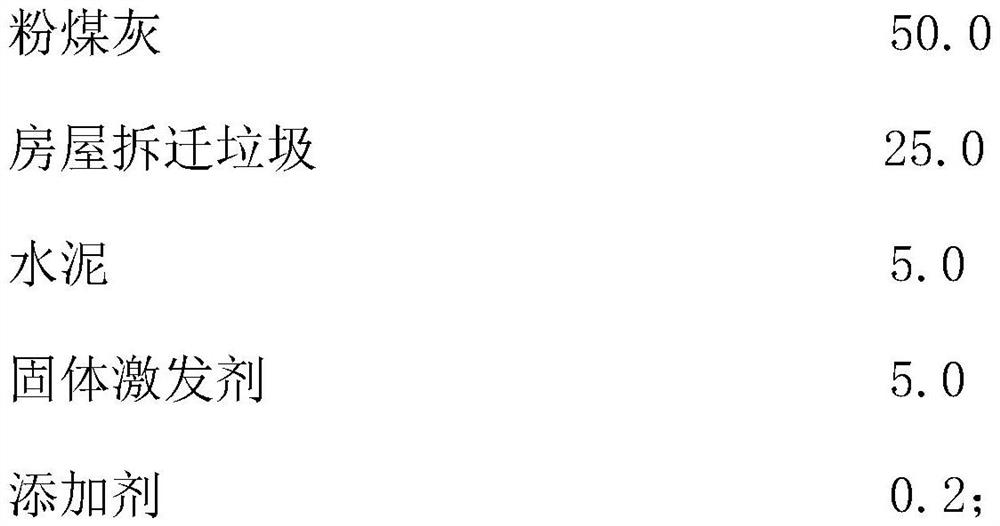

[0037] A one-component modified geopolymer, comprising the following raw materials in parts by mass:

[0038]

[0039] Solid activator comprises the raw material of following mass parts:

[0040] Instant Sodium Silicate 50.0

[0041] Instant dissolving sodium fluorosilicate 15.0

[0043] The modulus of instant sodium silicate is 1.4;

[0044] Additive comprises the raw material of following mass parts:

[0045] Polycarboxylate superplasticizer 65.0

[0046] Defoamer 10.0

[0047] Diutin 5.0.

[0048] The one-component modified geopolymer and water are mixed at a high speed at a mass ratio of 1:0.3 before grouting construction.

[0049] Fly ash crushed stone cold regeneration treatment process has the following steps:

[0050] (1) Spread and mix the one-component modified geopolymer and the milling material for the base course of lime-fly ash gravel at a mass ratio of 8.0:100.0;

[0051] (2) Level the evenly mixed fly ash and gravel r...

Embodiment 2

[0054] A one-component modified geopolymer, comprising the following raw materials in parts by mass:

[0055]

[0056] Solid activator comprises the raw material of following mass parts:

[0057] Instant Sodium Silicate 52.0

[0058] Instant dissolving sodium fluorosilicate 19.0

[0059] Sodium carbonate 21.0;

[0060] The modulus of instant sodium silicate is 1.5;

[0061] Additive comprises the raw material of following mass parts:

[0062] Polycarboxylate superplasticizer 70.0

[0063] Defoamer 12.0

[0064] Diutin 6.5.

[0065] The one-component modified geopolymer and water are mixed at a high speed at a mass ratio of 1:0.32 before grouting construction.

[0066] Fly ash crushed stone cold regeneration treatment process has the following steps:

[0067] (1) Spread and mix the one-component modified geopolymer and the milling material of the fly ash gravel base in a mass ratio of 9.5:100.0;

[0068] (2) Level the evenly mixed fly ash and gravel recycled materials...

Embodiment 3

[0071] A one-component modified geopolymer, comprising the following raw materials in parts by mass:

[0072]

[0073] Solid activator comprises the raw material of following mass parts:

[0074] Instant Sodium Silicate 55.0

[0075] Instant dissolving sodium fluorosilicate 22.5

[0076] Sodium carbonate 22.5;

[0077] The modulus of instant sodium silicate is 1.7;

[0078] Additive comprises the raw material of following mass parts:

[0079] Polycarboxylate superplasticizer 72.5

[0080] Defoamer 15.0

[0081] Diutin 7.5.

[0082] The one-component modified geopolymer and water are mixed at a high speed at a mass ratio of 1:0.35 before grouting construction.

[0083] Fly ash crushed stone cold regeneration treatment process has the following steps:

[0084] (1) Spread and mix the one-component modified geopolymer and the milling material for the base course of fly ash crushed stone at a mass ratio of 11.5:100.0;

[0085] (2) Level the evenly mixed fly ash and grav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com